Motivation

Semiconductor substrates such as Si wafers or masks for the next generation of extreme ultraviolet lithography (EUVL) are handled in a vacuum.

For nm structures and exact overlay, the reproducibility of the substrate evenness is a crucial factor, as unevenness results in structural distortions. Particles are problematic and heat input as well as thermal expansion must be taken into account.

Mechanical clamping devices (3-point suspension) cause sagging substrates, abrasion and poor heat contact.

Electrostatic “clamping” to a chuck with “zero expansion” is one alternative. With an electrical voltage between the chuck electrodes, the substrate can be held and, as required, even smoothed.

Benefits

- Substrate holder of highest evenness (< 50 nm PV for chucks for the EUVL masks) with precision manufacturing

- Thermal invariance with “zero expansion” materials

- Electrostatic forces (switchable and adjustable)

- Abrasion and particle generation are negligible

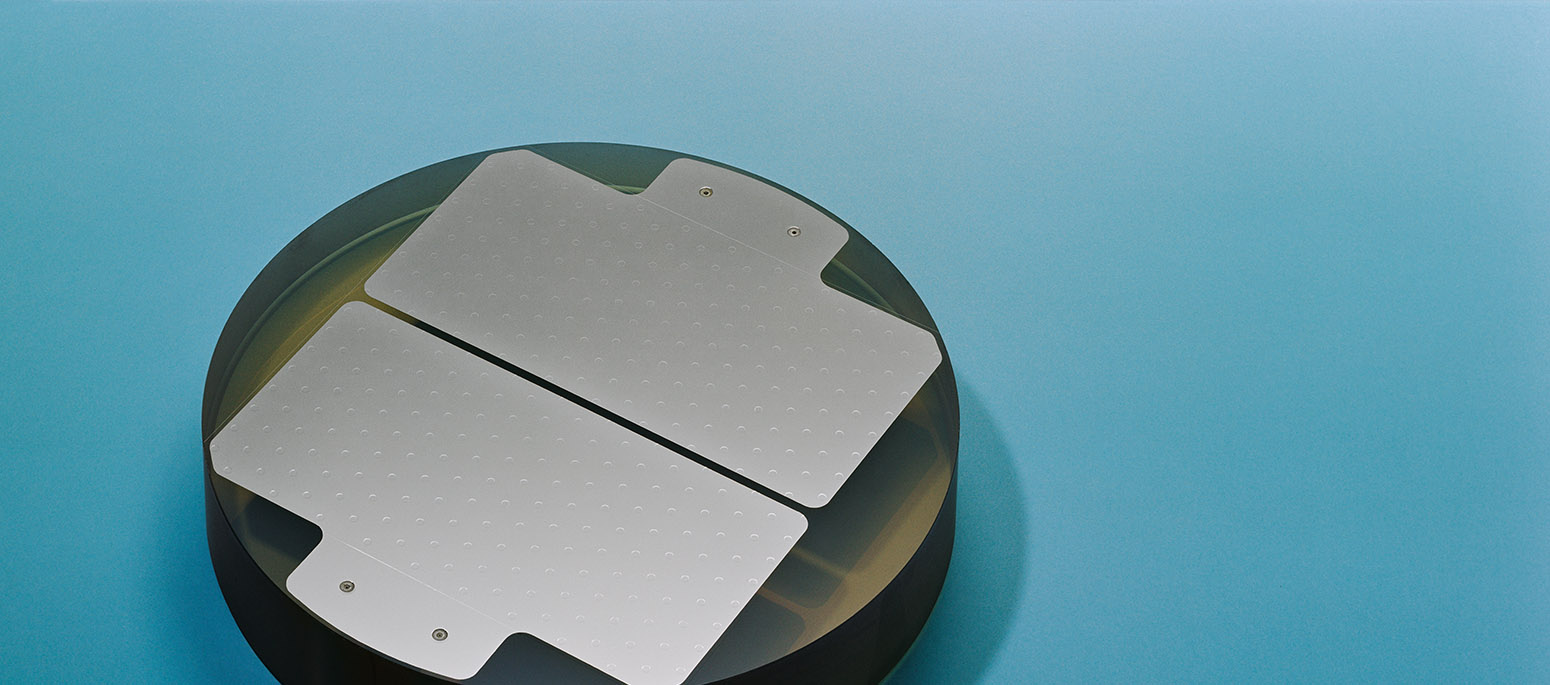

- Pin structured surface minimizes particle risk

- Lightweight design and cooling channels possible

Our work

The Fraunhofer IOF develops electrostatic chucks of the highest evenness for lithography applications. Unipolar and multipolar electrode structures are used:

- Development (CAD/FEM simulation) of next-generation wafer chucks (Si wafers with 450 mm diameter) for 22 nm node and below

- Diameter up to 12 inches

- Vacuum-compatible, non-magnetic

- Chuck materials with minimum (“zero”) thermal expansion

- Surface structuring with honeycomb or pin pattern

- In accordance with SEMI P40

- Kinematic chuck mounting

- Chuck characterization

- Integration in handling and metrology systems

- Sensor integration