The production of microlens arrays using photoresist reflow and following transfer with reactive ion etching (RIE) is an established technology.

Using an additional combination with polymer molding, a series of interesting further properties can be achieved.

Concave microlenses in SiO2 and Si

Reflow photoresist structures are normally convex. With an additional polymer molding step, however, the structure can be inverted and then transferred to the underlying silicon or glass substrate using RIE. One example is the realization of ultra-precise concave mirror arrays in silicon.

Aspherical lens profiles

The lens structures created during photoresist reflow usually have spherical surfaces. A desired aspherical profile (elliptical, parabolic) can be achieved using special RIE processes.

Structures generated in this way are also used as masters for subsequent production using polymer molding.

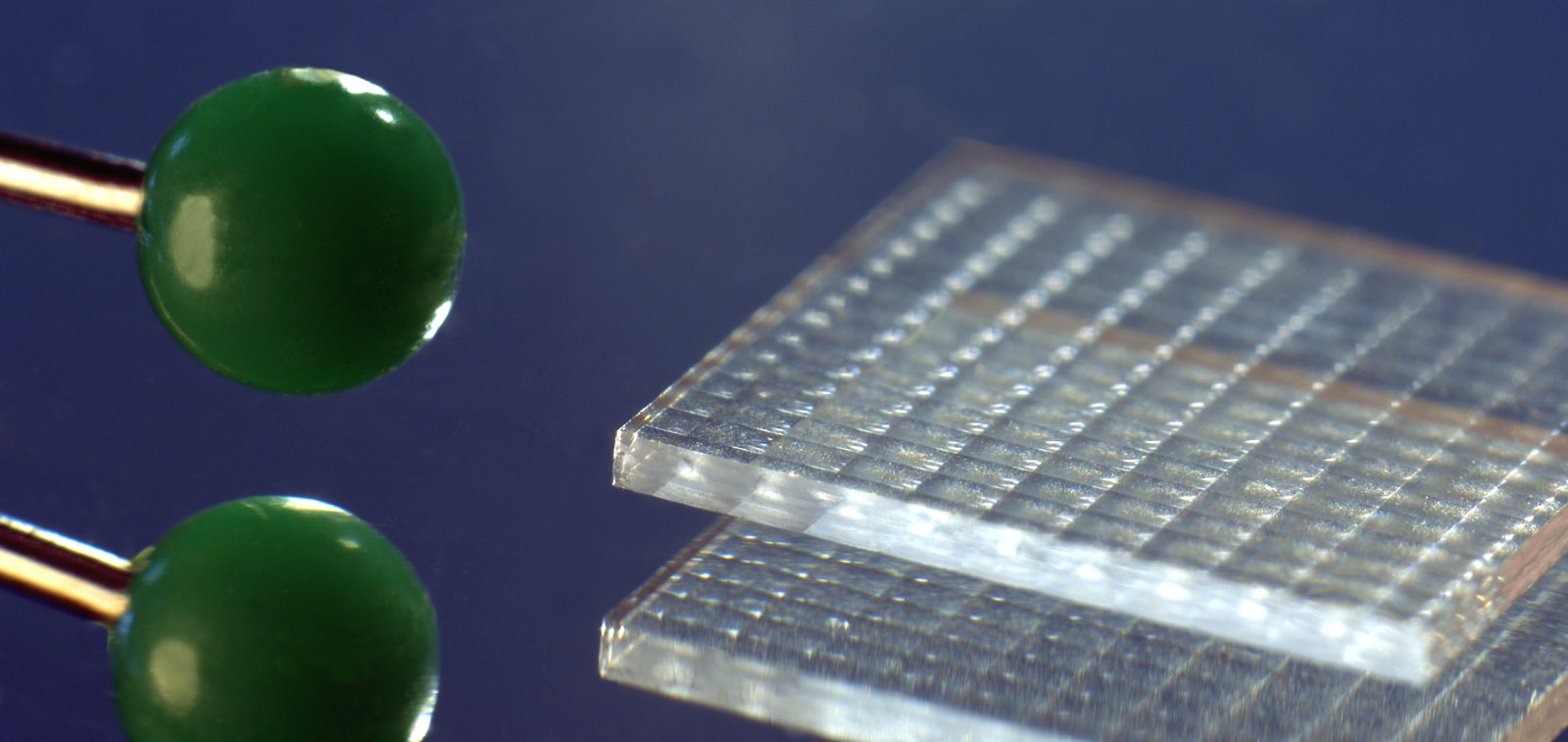

Microlens arrays with 100 % space factor

Photoresist reflow microlens arrays exhibit dead zones due to the lithographic resolution and the packing density of round lens bases.

With their virtually isotropic etching characteristics, RIE etching processes can modify the space factor. This makes it possible, for example, to produce hexagonally packed arrays of spherical lenses with 100 % space factor. These can, in turn, serve as molding masters.