Highly individualized integration of functions

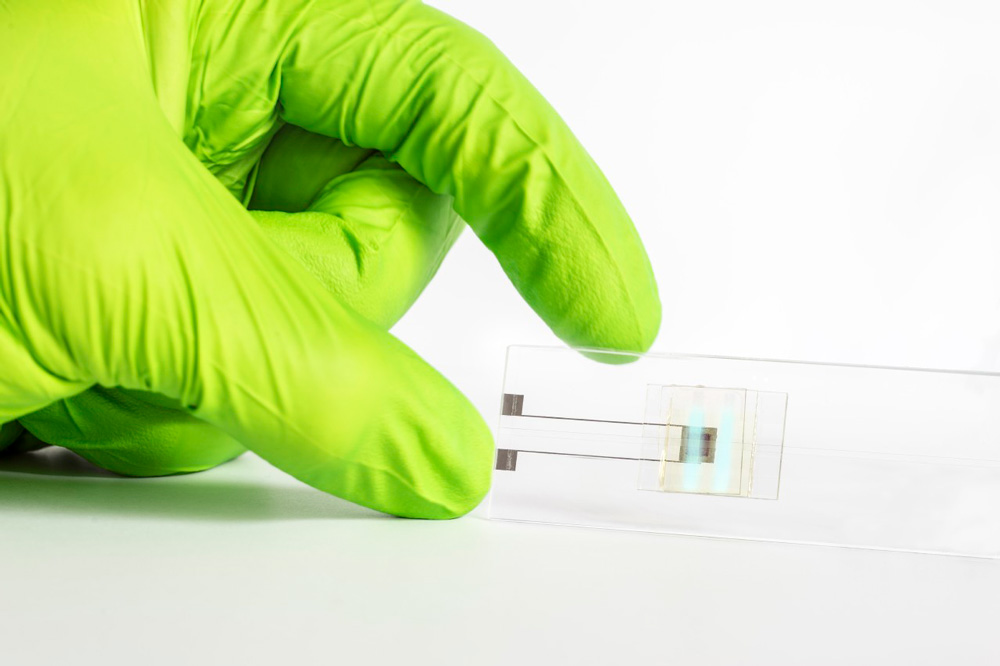

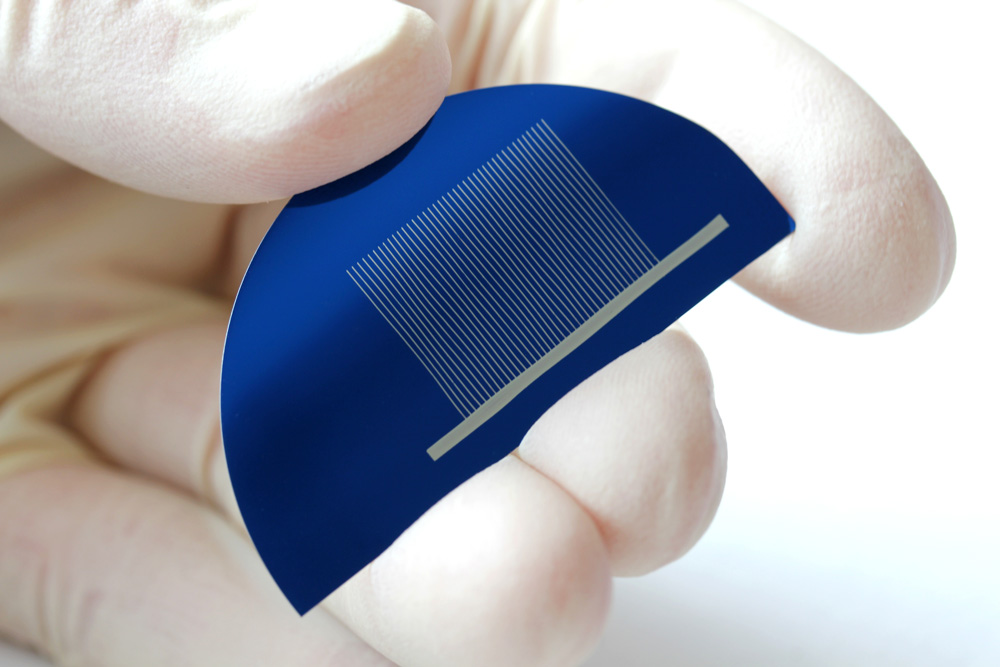

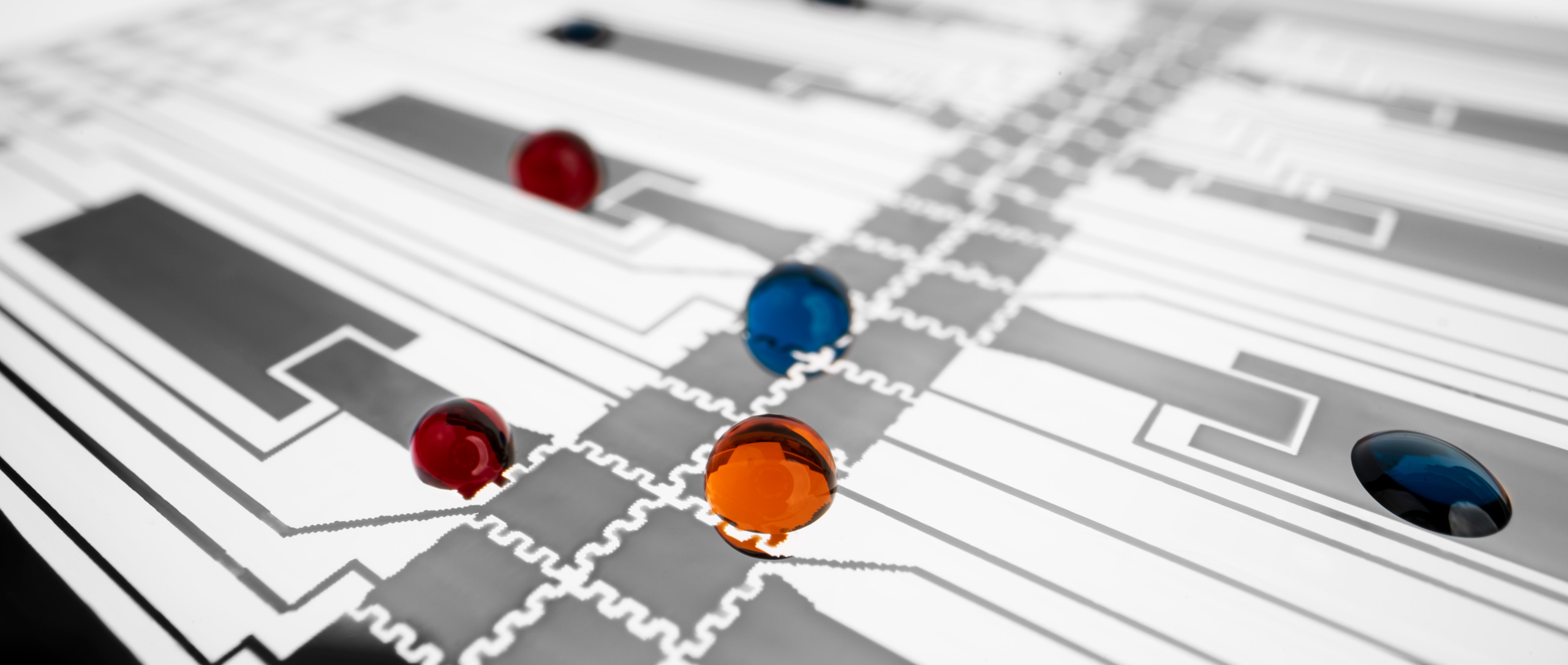

Inkjet printing of functional materials is a resource-saving digital structuring process which can be used to apply a wide range of different materials locally and contactless. Metals, polymers, and ceramics transferred into low viscous inks can thus be applied to any surface. The combination of different materials enables the production of numerous structures such as electrical conductors and sensory surfaces, as well as more complex components such as actuators, organic LEDs, organic solar cells, and much more.

The inkjet printing process mostly takes place in a normal atmosphere and at low process temperatures. This makes the entire process very cost-effective. It is also particularly suitable for the production of single components and rapid prototyping due to the high potential to customize the individual printed structures. Scaling up to high volumes is easily possible due to the digital design.

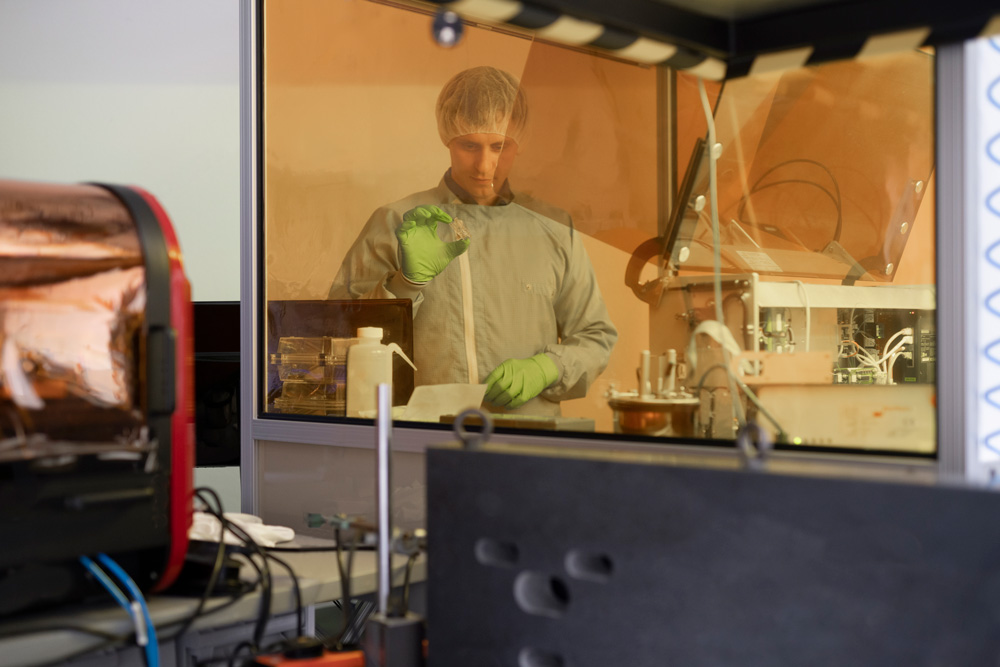

At Fraunhofer IOF, the entire process chain is investigated and developed, ranging from the pre-treatment of the substrates and the development of the printing process, to the targeted post-treatment of the printed structures. Our many years of experience lead to a targeted parameter optimization of the entire printing process.

Our range of services

We realize tailor-made solutions for our customers with the development of individual processes and process chains. Our range of services includes the selection of suitable materials and the development of inks, the development of targeted substrate preparation processes, the development of printing processes for the various materials and inks, and the targeted post-treatment of printed structures. In addition, extensive optical, electrical, and mechanical characterization of the printed structures is carried out at the customer's request.