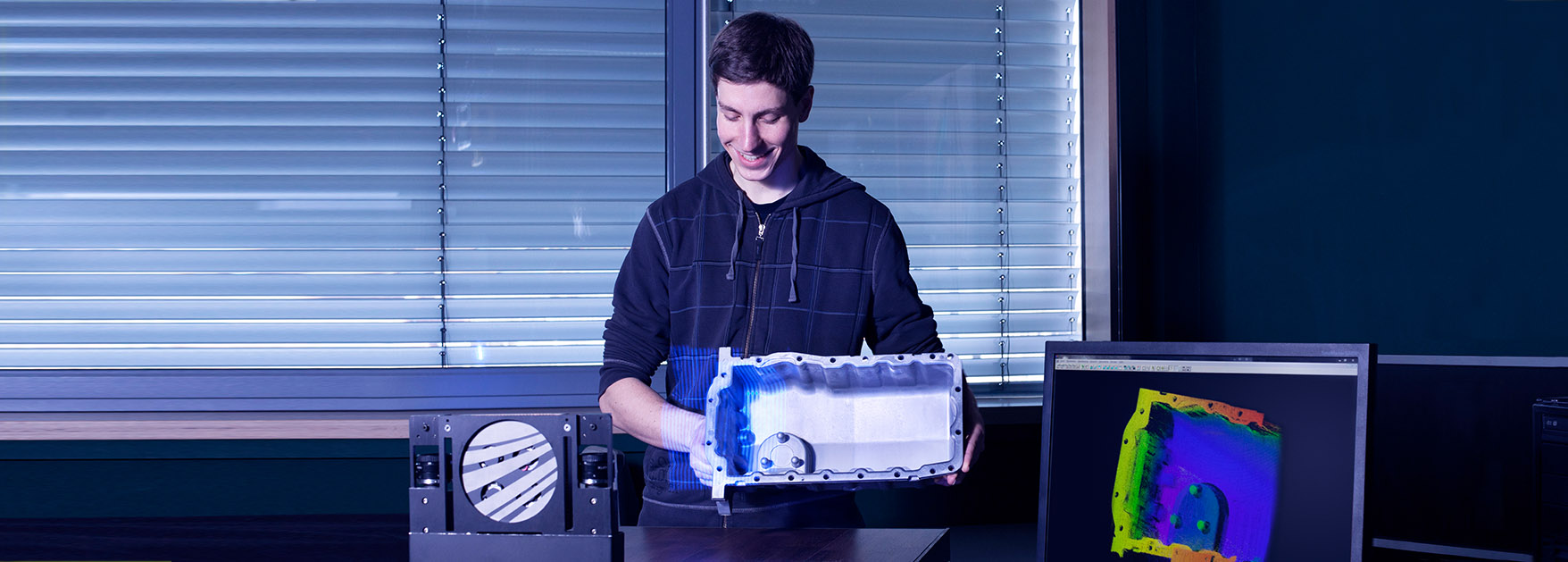

Fraunhofer IOF develops innovative optical measurement methods and systems according to customer-specific requirements. This includes optical 3D measurement systems with high metrological accuracy for a wide range of applications. Measurement volumes from a few cubic centimeters

to several cubic meters can be acquired with measurement frequencies of up to 55,000 3D data sets per second.

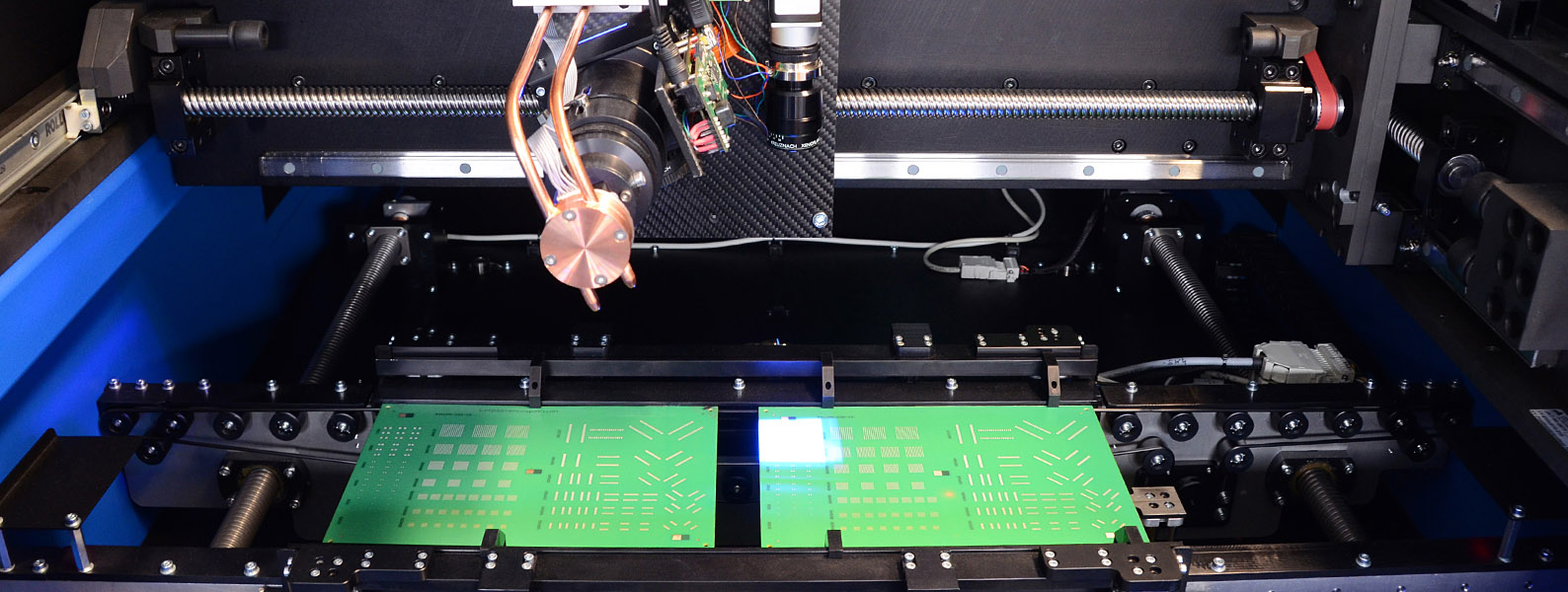

Furthermore, miniaturized micro-optical imaging systems based on single- and multi-aperture systems are developed and realized. The production can be performed on a wafer-scale and can be implemented directly on an industrial level.

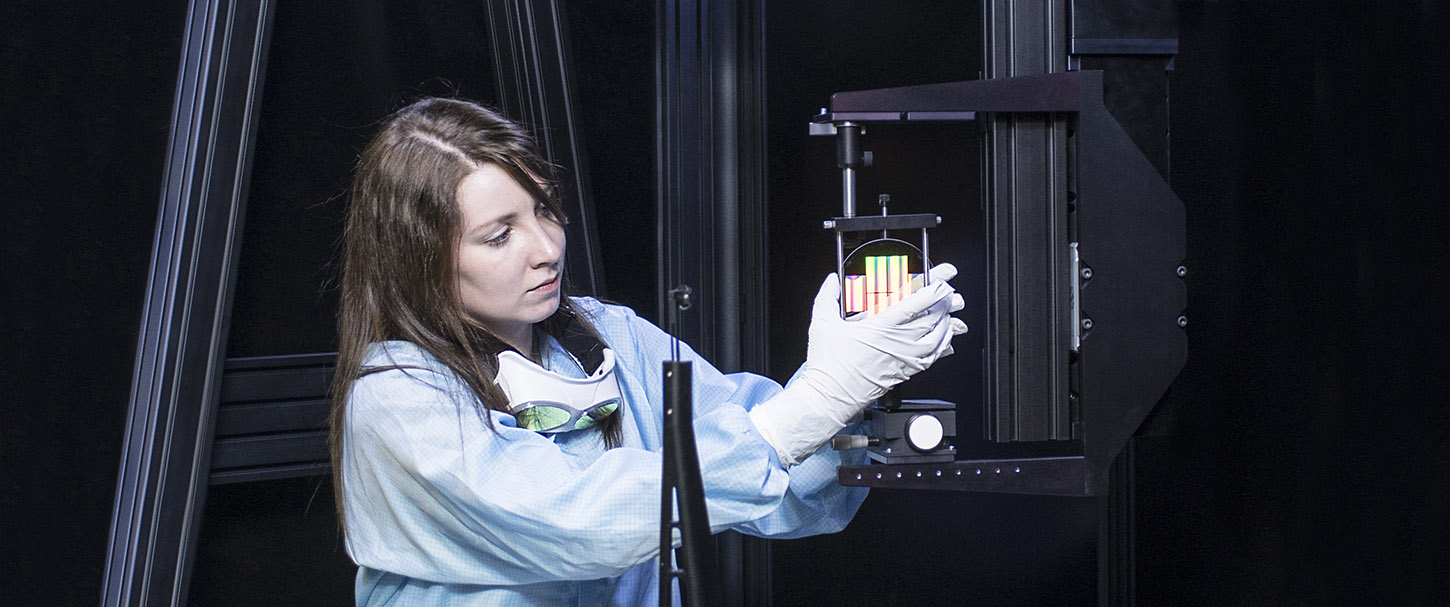

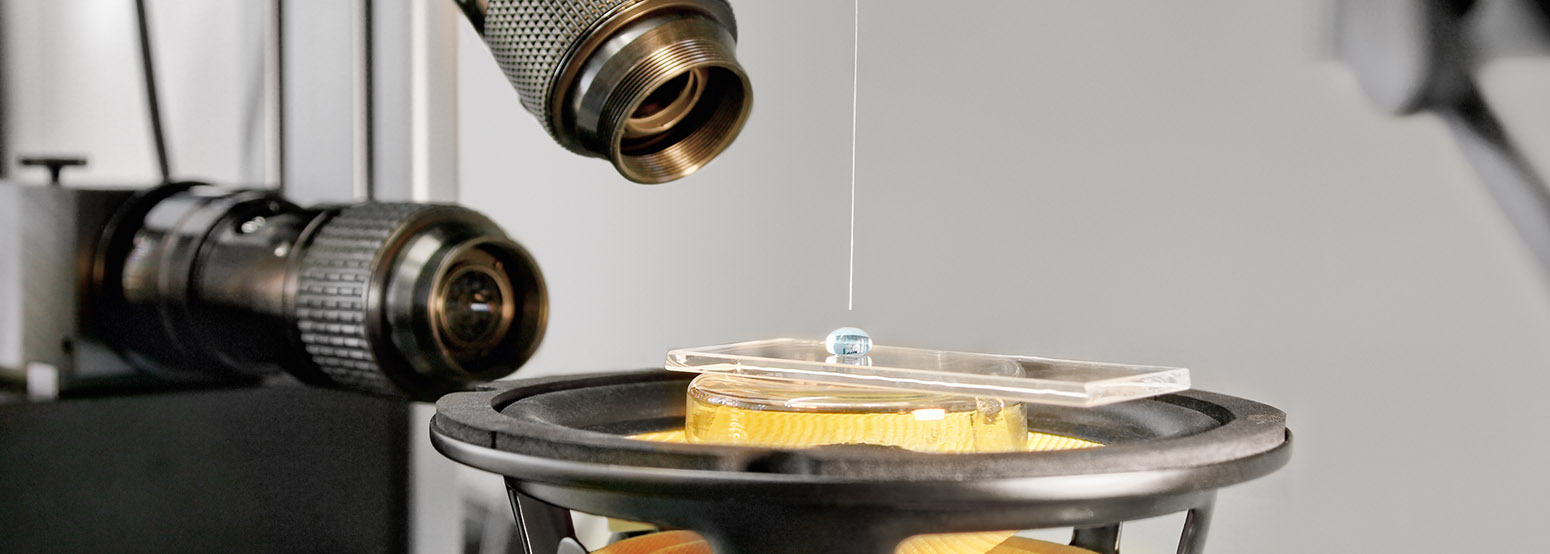

Fraunhofer IOF also holds a wide variety of optical and non-optical measuring systems. Examples are interferometers using CGHs (Computer Generated Holograms) as well as a computer tomograph with a resolution down to the micrometer range.