Motivation

Scalability of high power fiber lasers is closely linked to new fiber designs. As a consequence, new fiber optical components and processes are also necessary.

Characteristics and Technology

The Fraunhofer IOF Jena develops new joining technologies and processes for fiber optics and its components based on a CO2-laser.

High purity processes without any contaminations for splicing and tapering tasks can be provided.

Application

A CO2-laser is an efficient tool for manufacturing of different fiber laser components and fiber preparation processes with high precision, purity, and reproducibility:

- Splicing of fibers with similar or different fiber cross-sections

- Tapering of fibers and capillaries

- Collapsing of Photonic Crystal Fibers

- Stripping of coated fiber material

- Shaping of fiber end facets

- Cleaning of fiber tips

- Splicing of special rod type fibers, etc.

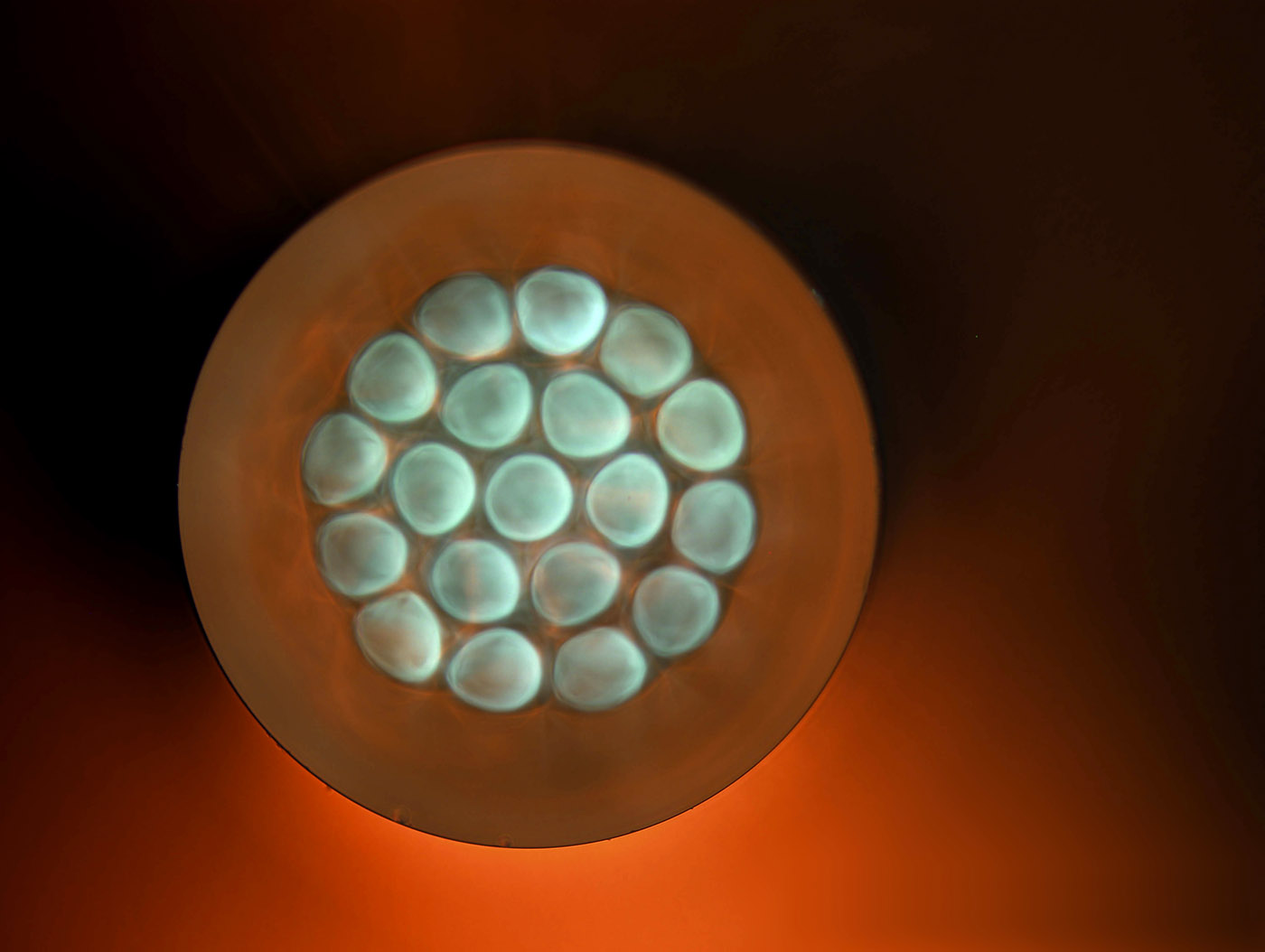

Furthermore, pump couplers and beam shaping elements are manufactured.

The development of special customized processes and devices are possible.