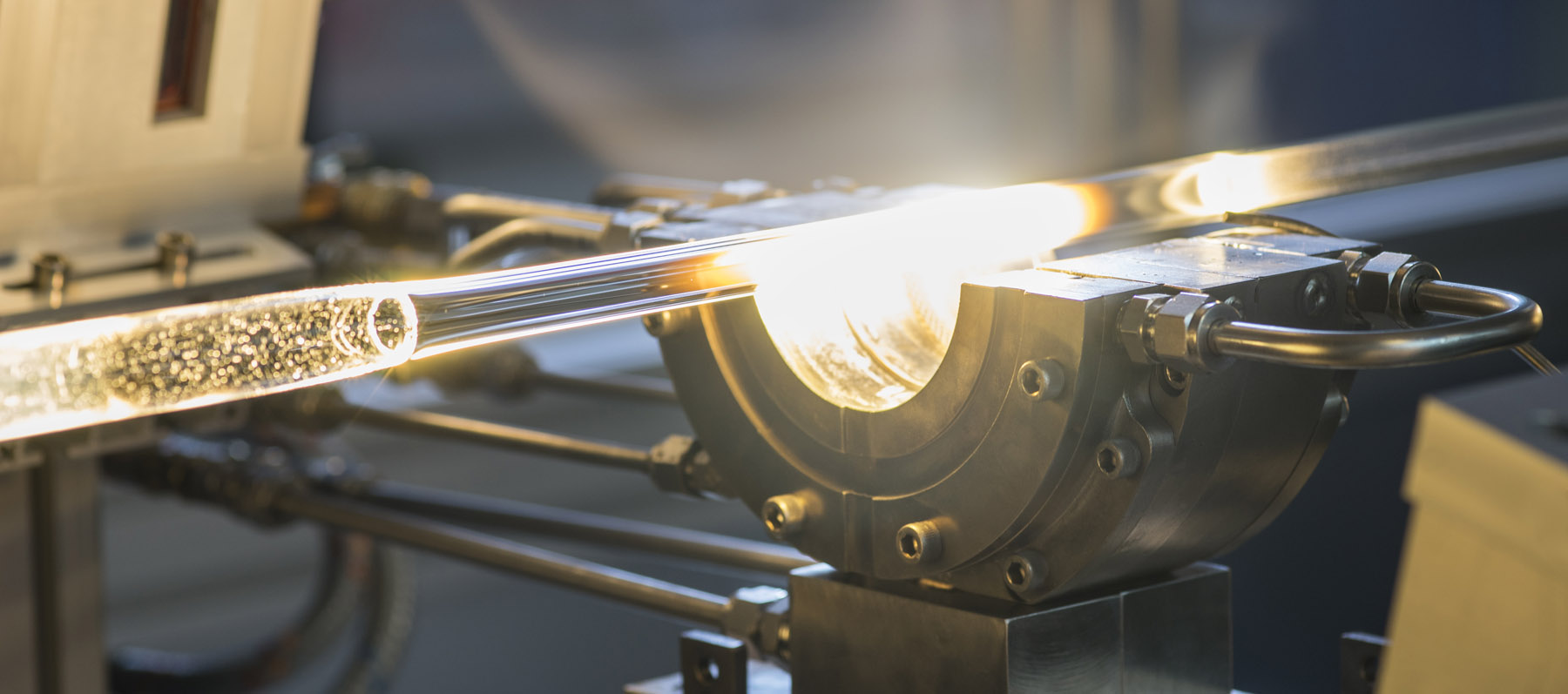

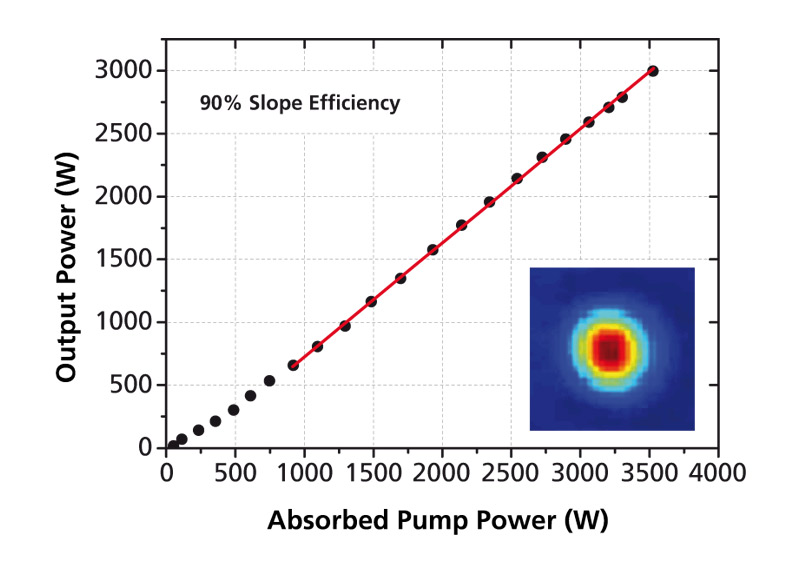

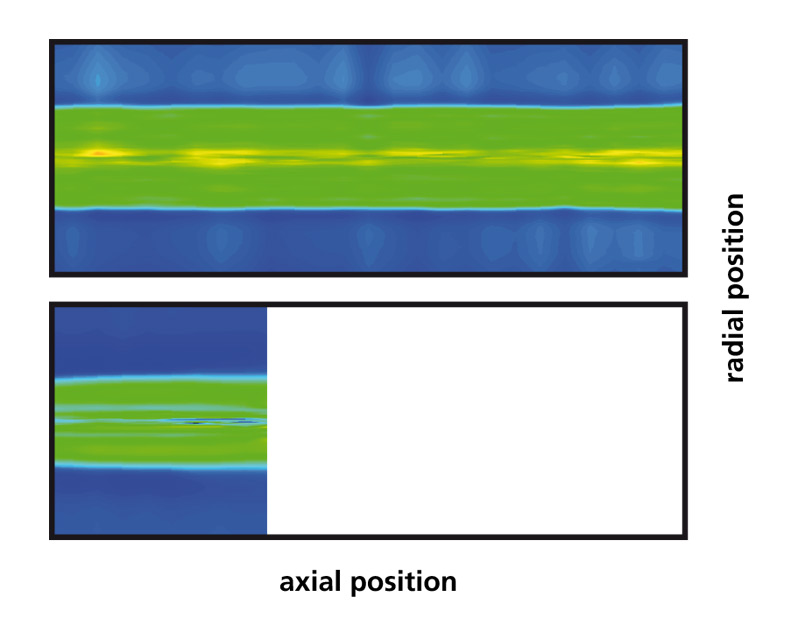

It is well known that lasers are important information and energy carriers, as wear-free tools, and contact-free measuring devices with widely spread applications in industry and science. For high power applications in particular, fiber lasers have many advantages in comparison to other laser concepts, for example with regard to highest output power levels with excellent beam quality. In spite of the outstanding properties of fiber lasers after an initial exponential increase of output power, further power scaling has dropped in the last few years. This is not because of barriers of applications but a new fundamental physical limit called thermally induced mode instability. Since 2011 the technology for preform fabrication has been constructed at Fraunhofer IOF with the aim of pushing and overcoming the existing limits by realizing innovative, new fiber designs. The fibers fabricated at the Fraunhofer IOF Jena are produced by MCVD (modified chemical vapor deposition) technology combined with solution doping technology. To prevent unwanted nonlinear effects, fibers with comparable large core diameters are fabricated. In combination with the requirement of fibers allowing for excellent beam quality, one consequence is that the fiber core must have a very small increase of refractive index. This requirement is challenging and places great demands on the precision of many process parameters for fiber fabrication. For the first time, a new record of 3 kW output power with excellent beam quality and a very high slope efficiency could be demonstrated with a fiber laser system built from fibers fabricated at the Fraunhofer IOF (Fig. 2). Previously, power levels up to 2.3 kW were reached in similar setups built from commercially available fibers. The necessity of combing the whole process chain from fiber design to application, which guarantees short paths of information, is demonstrated by the great success with the fibers fabricated at the Fraunhofer IOF. In future the development fibers at the Fraunhofer IOF will be pushed further. Besides the development of new fiber designs, the improvement of fiber homogeneities and yield will also be important work packages (Fig. 3).

Authors: Nicoletta Haarlammert, Stefan Kuhn, Christian Hupel, Franz Beier, Johannes Nold, Thomas Schreiber