The University of New Mexico, with the support of Fraunhofer IOF, was able to show that in the future the list of coolants and refrigerants will have to be extended: Optically cooled fused silica.

Optically cooled fused silica

The University of New Mexico, with the support of Fraunhofer IOF, was able to show that in the future the list of coolants and refrigerants will have to be extended: Optically cooled fused silica.

Normally, a material heats up when it is irradiated with laser light. However, under certain circumstances the material may cool down. This cooling effect is achieved in glass, as well as in solids in general, with laser light by exciting individual ions within the material to fluoresce. If the average wavelength of the fluorescence is smaller than the excitation wavelength, energy, and thus heat, is transported out of the material with the light emission.

Our colleagues from the USA have succeeded for the first time in reducing the temperature in fused silica with the aid of a laser. Although fused silica is used everywhere in optics due to its exceptionally good properties, in previous experiments it could not be cooled due to very small but unfortunately for laser cooling too high losses.

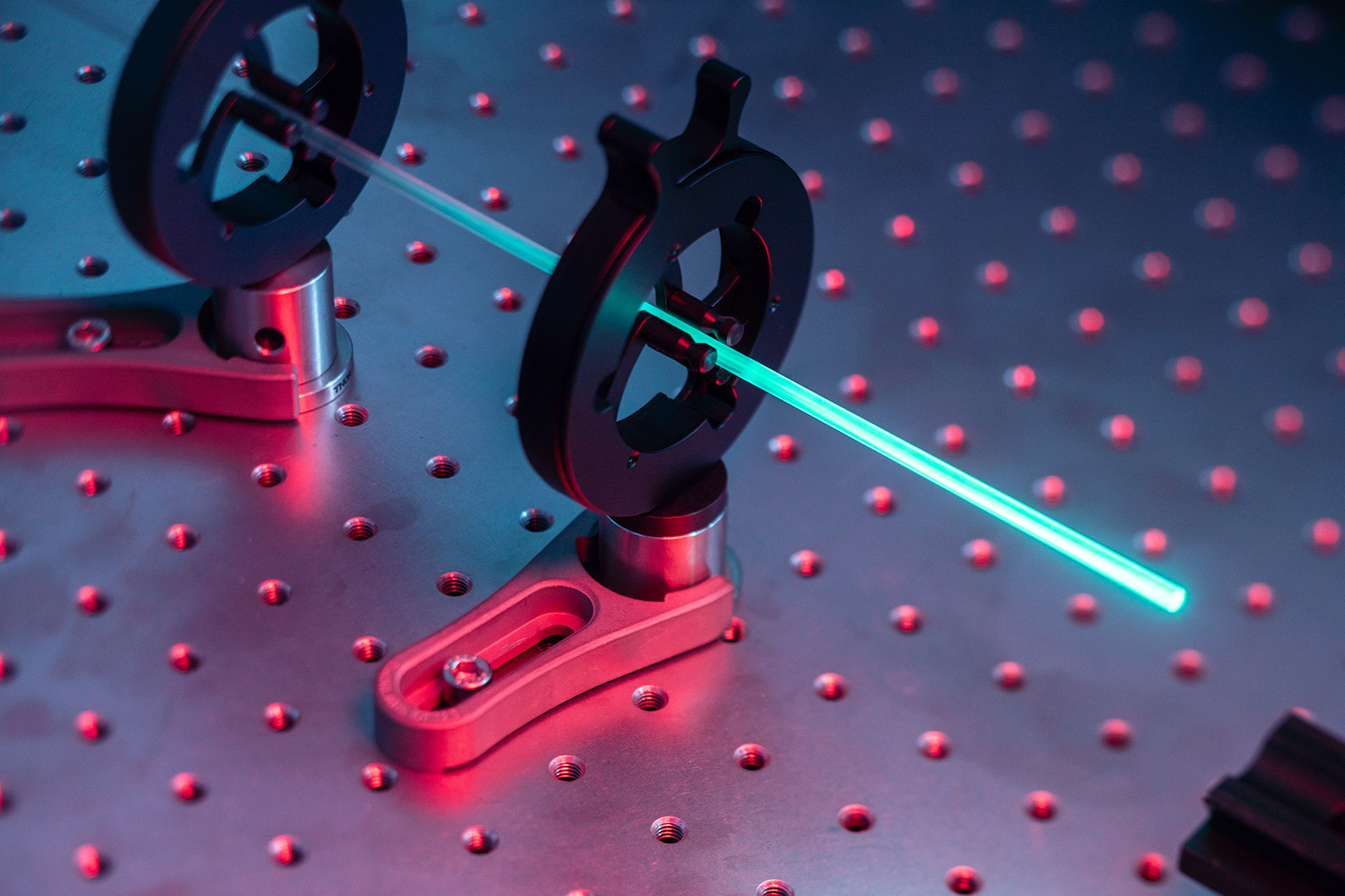

For their first series of experiments to cool fused silica with laser light, the researchers at the "Center for High Technology Materials" at the University of New Mexico (USA) needed high-purity glass doped with laser ions. The Fraunhofer IOF uses processes for this purpose that are otherwise used to manufacture Ytterbium-doped glass fibers for fiber laser systems. Here, too, low losses are required to generate high output power levels - a stroke of luck for both research areas.

Dr. N. Haarlammert, responsible for the fiber technology and therefor glass manufacturing, explains: “During the MCVD manufacturing process, a tube of fused silica is heated uniformly with several burners while a gas mixture is passed through. The enormous heat causes a chemical reaction of the gases with the glass tube. The gases, which also contain the laser ions, are converted into glass dust and finally fused into glass.”

In summary, Dr. T. Schreiber, head of the Laser- and Fiber Technology department, adds: “We are very grateful for the work of our colleagues at the University of New Mexico. The realization of the laser cooling impressively demonstrates the quality and purity of the process, that was established at the Fraunhofer IOF Jena.”

In the future, advances in solid-state laser cooling may lead to all-optical, compact and vibration-free cryogenic cooling, and as an application, reduce thermal noise in semiconductor-based single-photon detectors or quantum information processing circuits, among others.

Mobini, E., Rostami, S., Peysokhan, M. et al. Laser cooling of ytterbium-doped silica glass. Commun Phys 3, 134 (2020).