Functional Surfaces and Coatings

Surfaces and coatings play a decisive role in the function and performance of optical components and systems. Through surface treatment and coating, new optical and functional properties can be realized precisely. We develop solutions to problems along the entire process chain, both in the laboratory and in cooperation with companies in the coating industry and end users.

Our services

- Design of suitable surface, layer and material structures

- Coating of thin single layers up to complex interference layer systems

- Development of technologies for coating and nanostructuring

- Technology transfer from laboratory to industrial applications

- Surface and layer characterization, comprehensive and application-oriented

- Resistance tests and failure analysis

- Development and implementation of practical and scalable process chains

Extensive competencies and special expertise at Fraunhofer IOF

Functional coatings and surfaces are essential components of optical systems. Extensive expertise exists in the design of optical coating systems, in the development of coating processes for different applications and in the characterization of surfaces and coatings. Highly reflective coating systems for optics in the EUV and X-ray range as well as the functionalization of plastic surfaces deserve special mention.

We can also offer outstanding experience in the following areas:

- Design of optical coatings

- Virtual coating runs for design and process optimization

- Characterization of optical coatings

- Scattered light measurement and modeling of surfaces, multilayer systems and materials

- Elucidation of functionally relevant structural properties of surfaces and coatings

- Design and analysis of functional surface structures: hydrophobicity, oleophilia etc.

- EUV and X-ray coatings

- VUV, NIR and VIS coatings

- Coating of plastic optics (especially also scratch resistant and super broadband anti-reflective coatings)

- Conformal coating of highly curved components and grating structures

- Transparent and conductive coatings

- Production of 2D materials

Coating technologies at Fraunhofer IOF

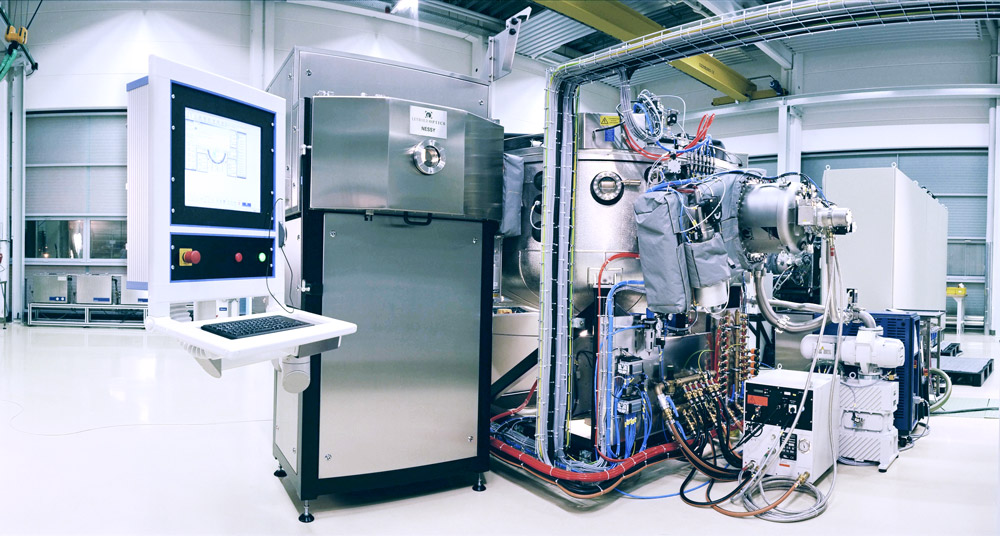

In order to effectively develop solutions for a wide range of applications and requirement profiles, especially in the field of optical components and systems, Fraunhofer IOF has a broad pool of coating processes at its disposal, ranging from commercially available industrial facilities to customized individual solutions.

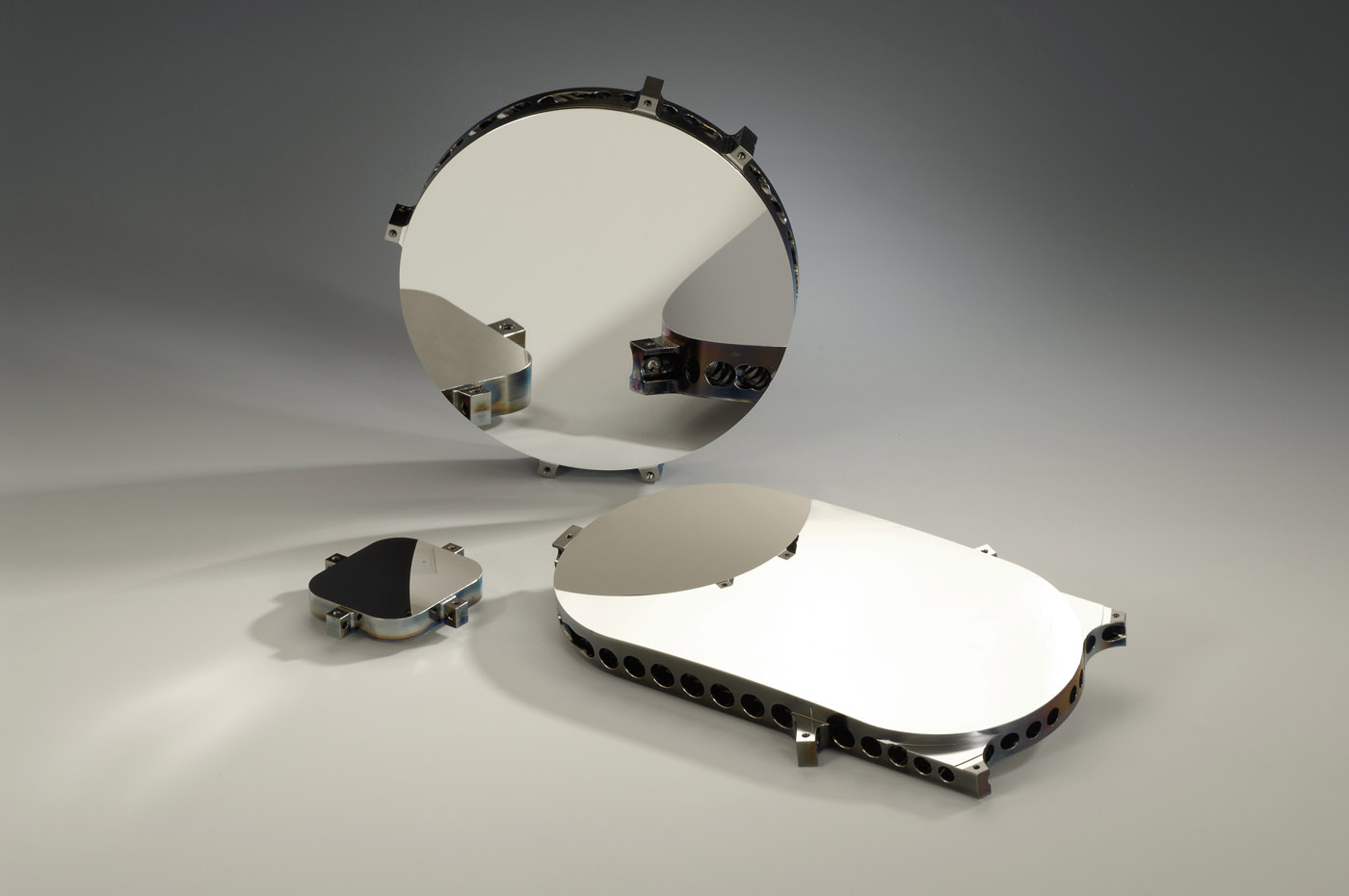

The possible diameters of the components to be coated range from small microlenses with a few millimeters to large mirrors with diameters of up to 500 mm. The most important coating technologies currently are:

- (Plasma- and ion-assisted) vapor deposition

- (Magnetron-) sputtering

- Atomic layer deposition

- Sol-gel coating

Analysis methods at Fraunhofer IOF

An essential prerequisite for these developments is a comprehensive pool of analysis and characterization methods as well as solid interfaces to the design and production of optical components and systems. Both commercial tools and special in-house developments are used. Our key focus areas are:

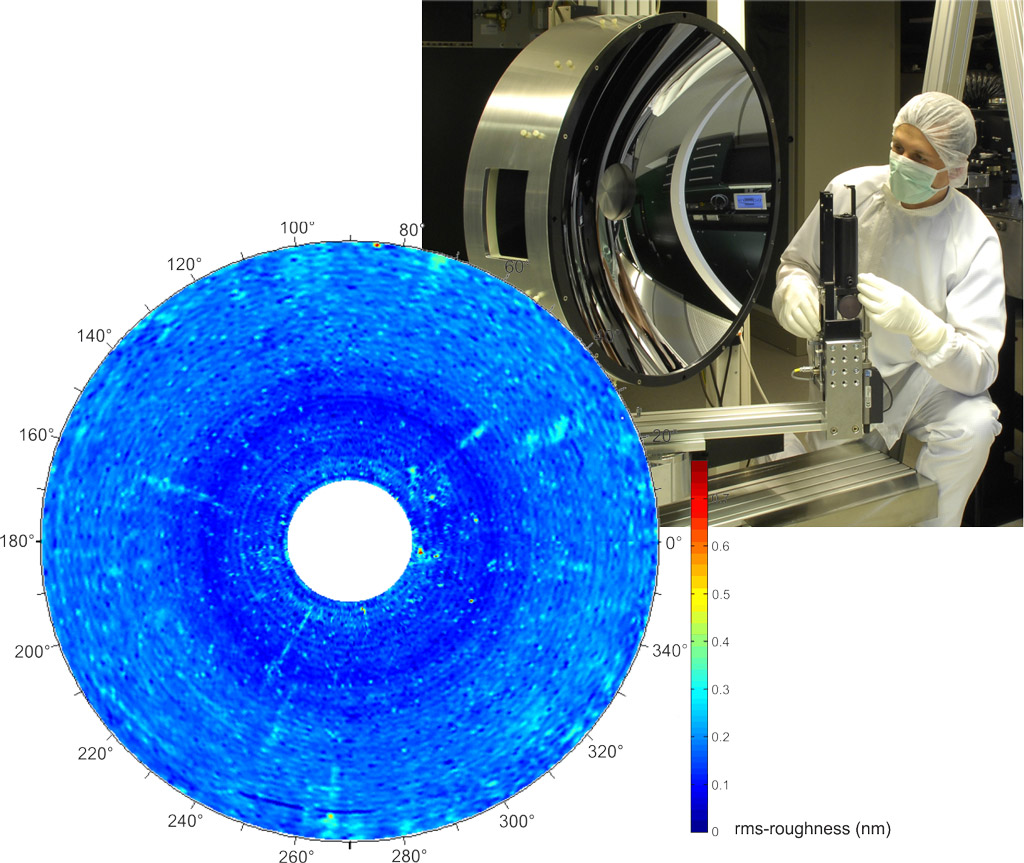

- High-resolution methods for the analysis of roughness and morphology (atomic force microscopy, scanning electron microscopy, white light interferometry, laser scanning microscopy)

- Analysis of optical properties (spectrophotometry, highly sensitive angle-resolved and total scattered light measurement)

- Analysis of functional properties (wetting analysis, adhesive strength, scratch resistance / tribology, environmental resistance)

We develop and apply methods which are highly sensitive and allow maximum gain of knowledge. They should, however, also be economical and practicable. Additionally, we especially strive for standardization and resilient integration into certified process chains. We are an active member in VDI committees and in DIN/ISO TC 172/SC 9 “Laser and electro-optical systems”.

In addition, we develop customized scattered light-based measuring systems and sensors, which allow a highly efficient, contactless and fast determination of roughness and defects. The systems can be used in a wide range of applications - from machine components to optical surfaces and can be directly integrated into existing manufacturing processes.

Fields of application

Our solutions cover a wide range of applications from extreme UV to the infrared spectral range. Our key focus areas are among others:- Highly reflective and durable mirrors for astronomy and space applications

- Precision coatings for lithography, inspection and measuring systems

- Broadband antireflection coating of plastic optics for camera and sensor systems (AR-plas and AR-plas2)

- Scratch-resistant antireflective coatings for display covers in automotive engineering, LIDAR systems and glasses

- Conformal coatings of complex components and microstructures

- Functional surfaces for bio- and medical technology

- Components for laser and quantum communication systems

- Coatings for crystals

We also transfer our expertise in the field of optical components and systems to technical surfaces and vice versa. This fusion enables multifunctional surfaces that combine, for example, excellent optical properties with high scratch resistance and self-cleaning properties.