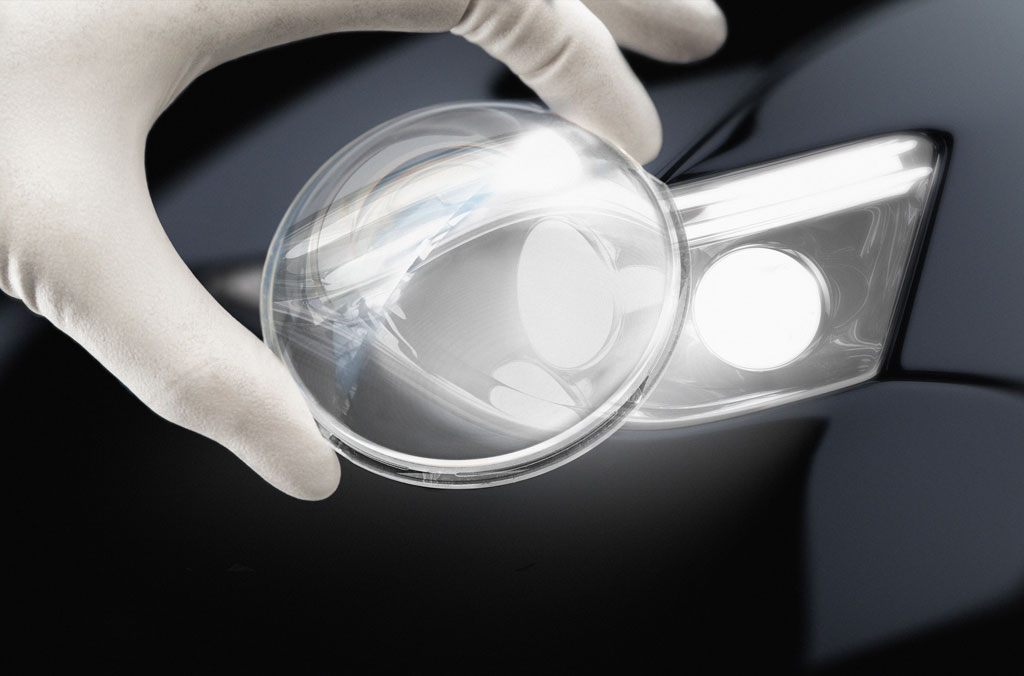

Individual functionalization of plastic optical surfaces

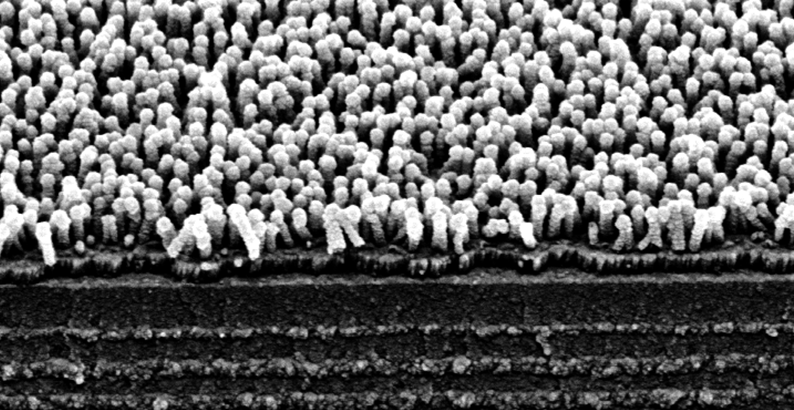

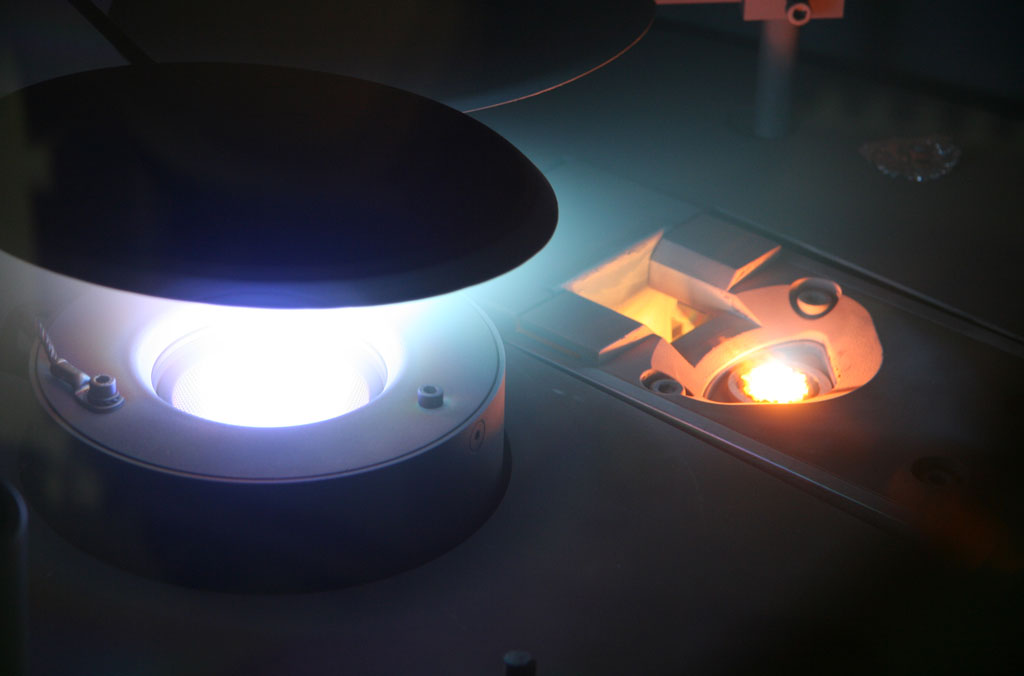

The processes used for coating glasses are not easily transferable to plastic optical components. The special properties of polymers must be taken into account, e.g., water and gas exchange with the environment, expansion coefficients and interactions with high-energy radiation.

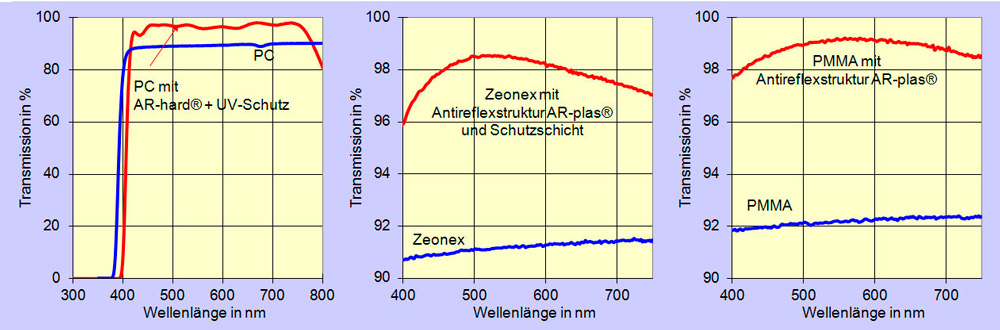

Along with the optical performance (usually as an antireflective function, AR, antireflection coating), the adaptation of intrinsic layer properties plays a decisive role in this context. Additional functions such as higher scratch resistance, antifingerprint or antifog properties are often requested and incorporated into the coating development.