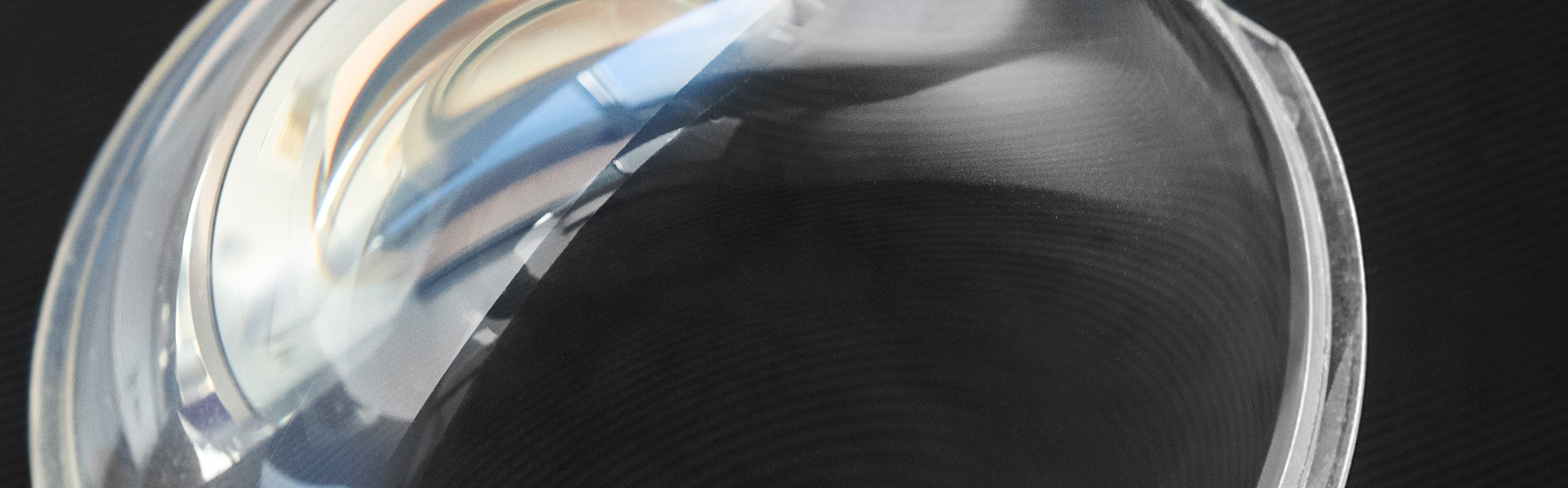

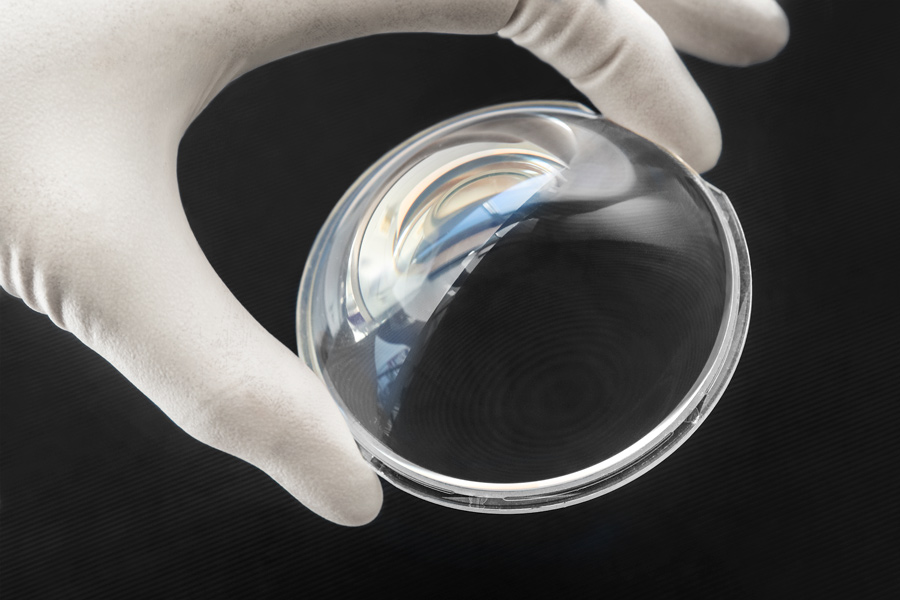

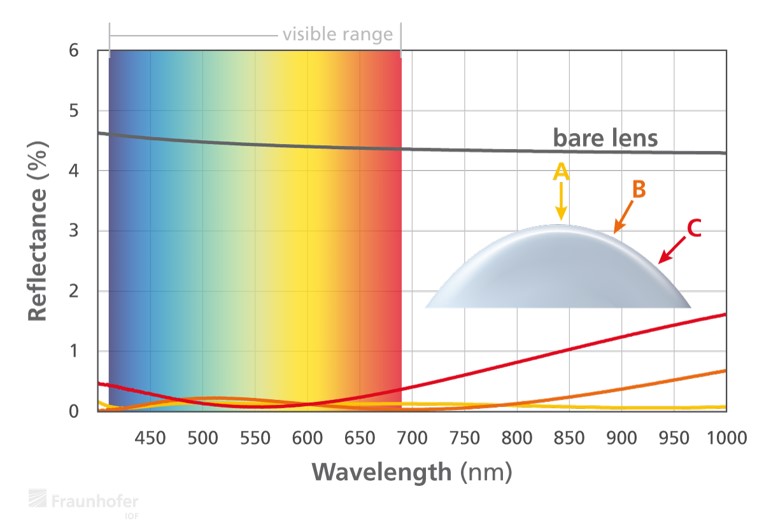

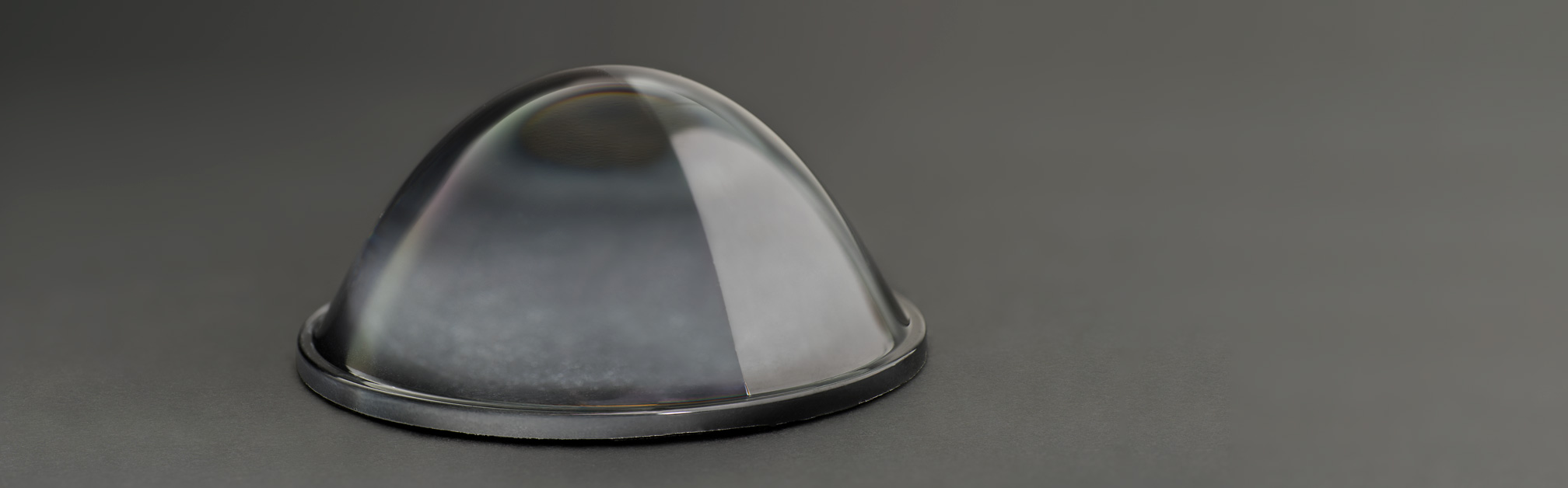

Transparent optical coatings play an important role in tailoring light. Through the use of thin films, it is possible to modify the surface depending on the environmental conditions. Fogging, which is a disturbing effect, occurs when small droplets adhere to the surface. It reduces the efficiency of optical surfaces and can also pose a significant safety risk (e. g. visors and glasses).

An extensive analysis of commercially available antifogging products concluded that hydrophilic or water-absorbing materials are theoretically suitable to counteract fogging. However, these are too soft or not long-lasting enough for most practice-orientated applications. The chemical components that achieve the antifogging effect must be buried deep in the composite material. It should therefore affect the mechanical stability, but not the optical properties of the surface.

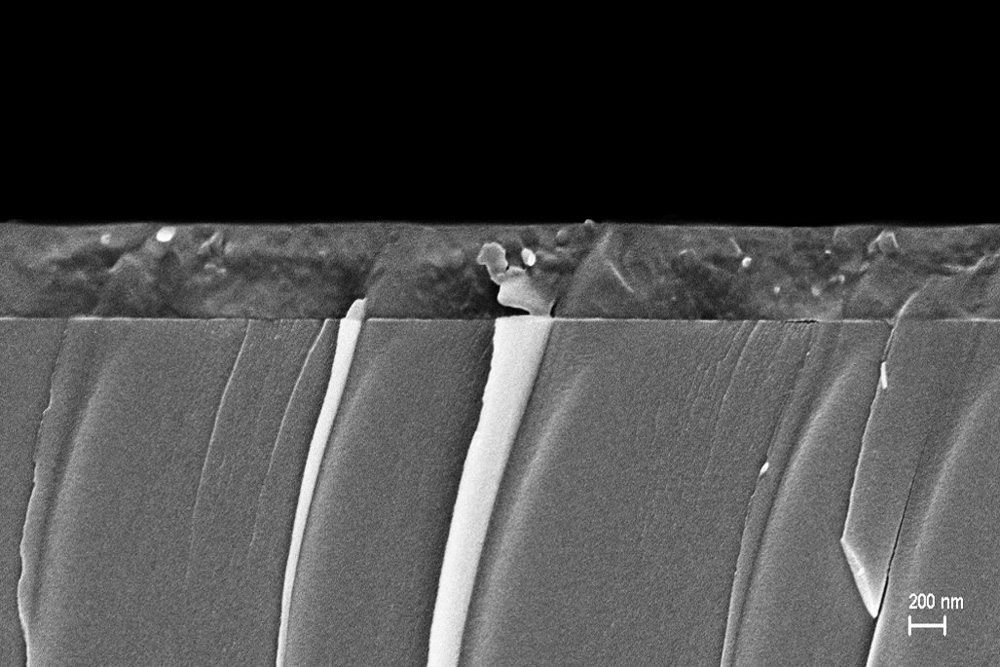

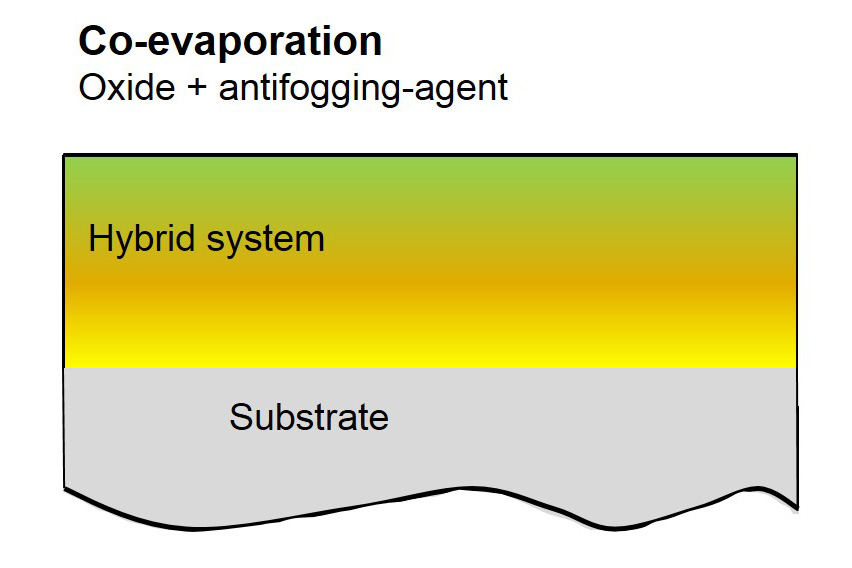

In the course of the evaluation of different low molecular hydrophilic polymers, for the first time cellulose acetate (CA) could be deposited by thermal evaporation. The homogeneous layers have a contact angle lower than 10° which emphasizes the good hydrophilic property even in long-term tests. Subsequently, first experiments of combined evaporation of CA and SiO2 have been carried out and lead to good approaches for functional surfaces.

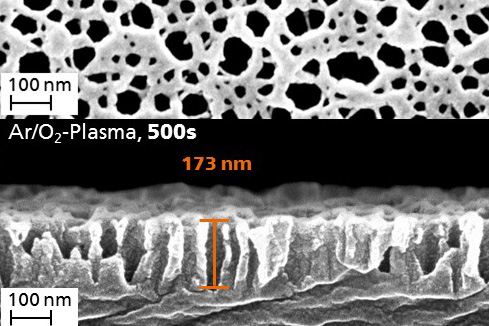

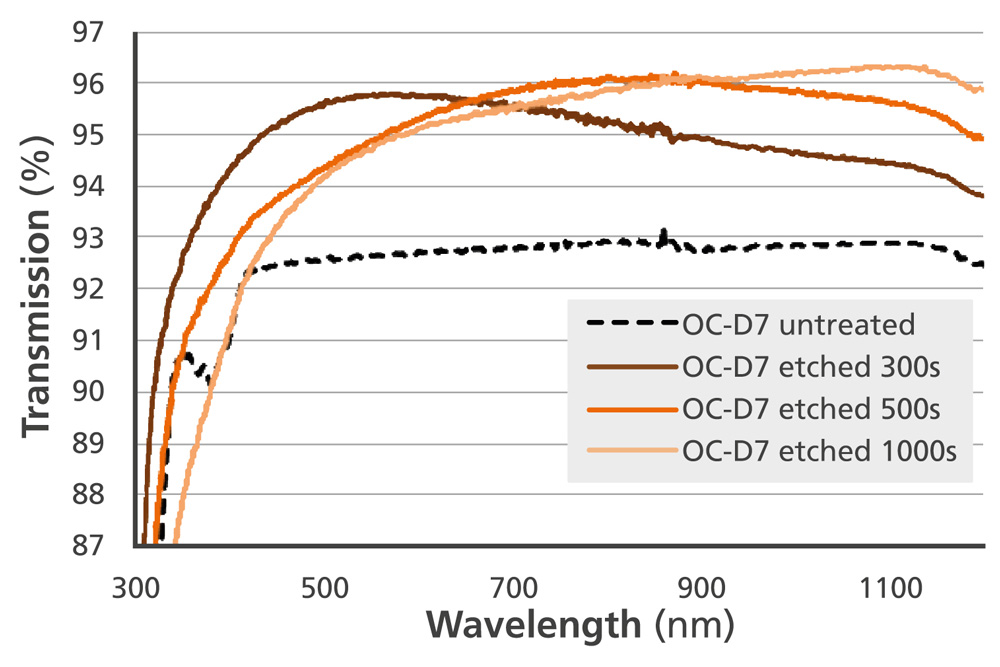

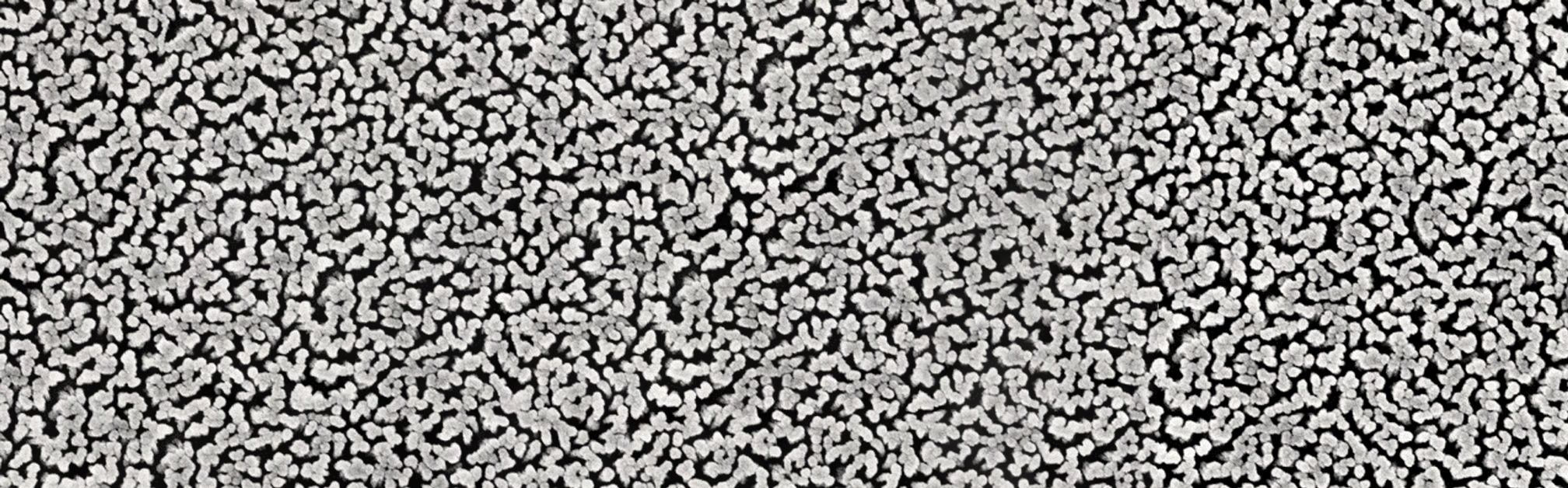

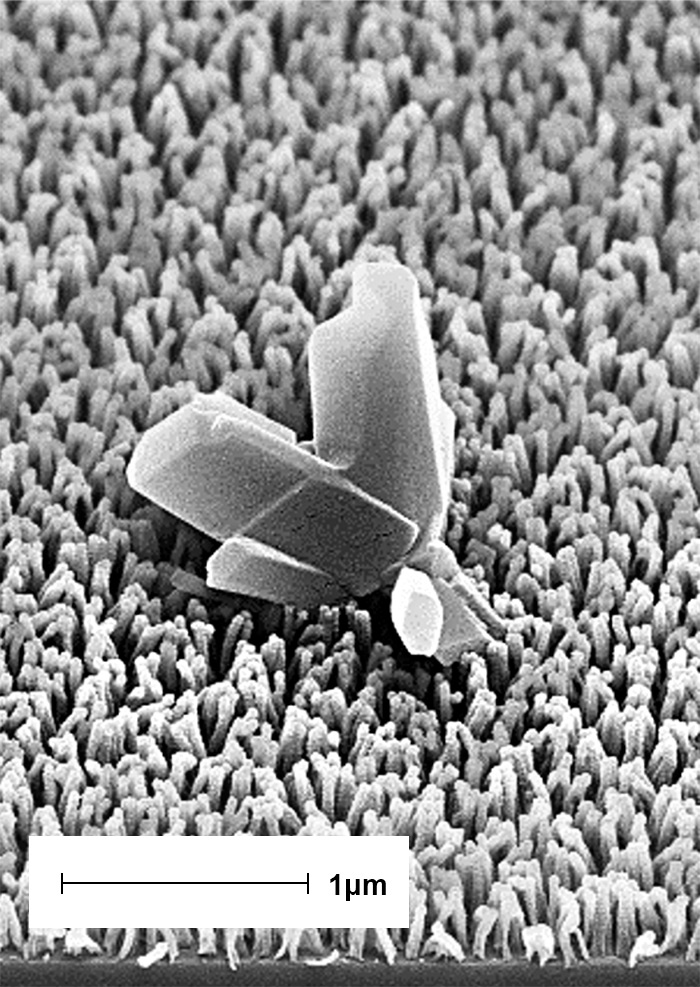

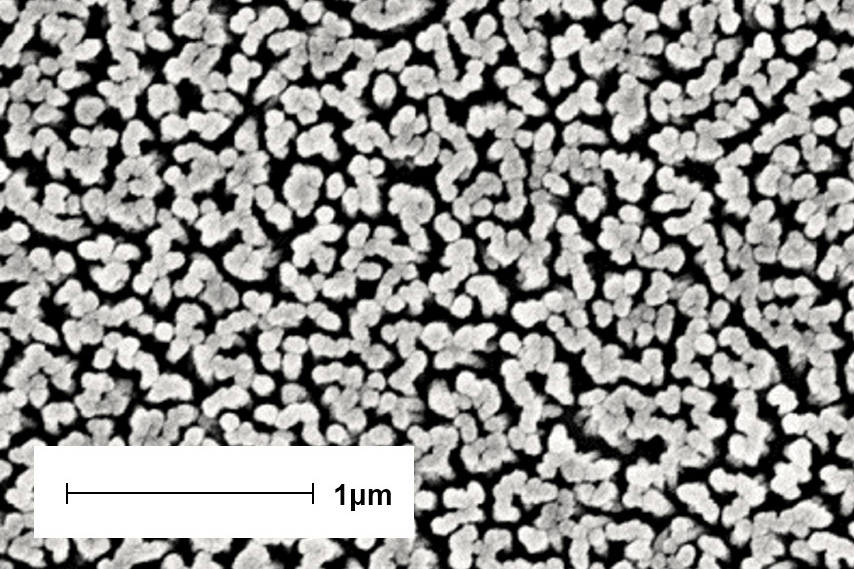

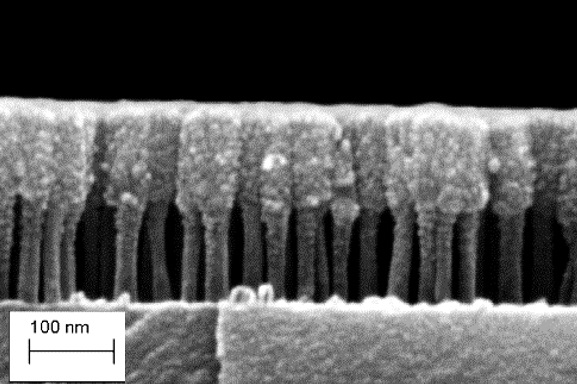

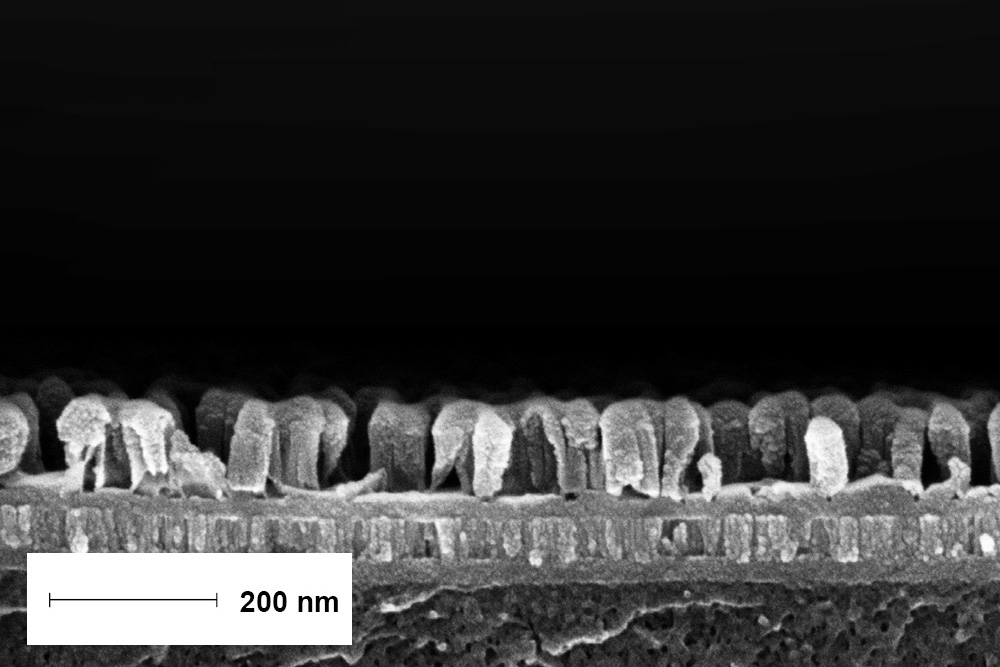

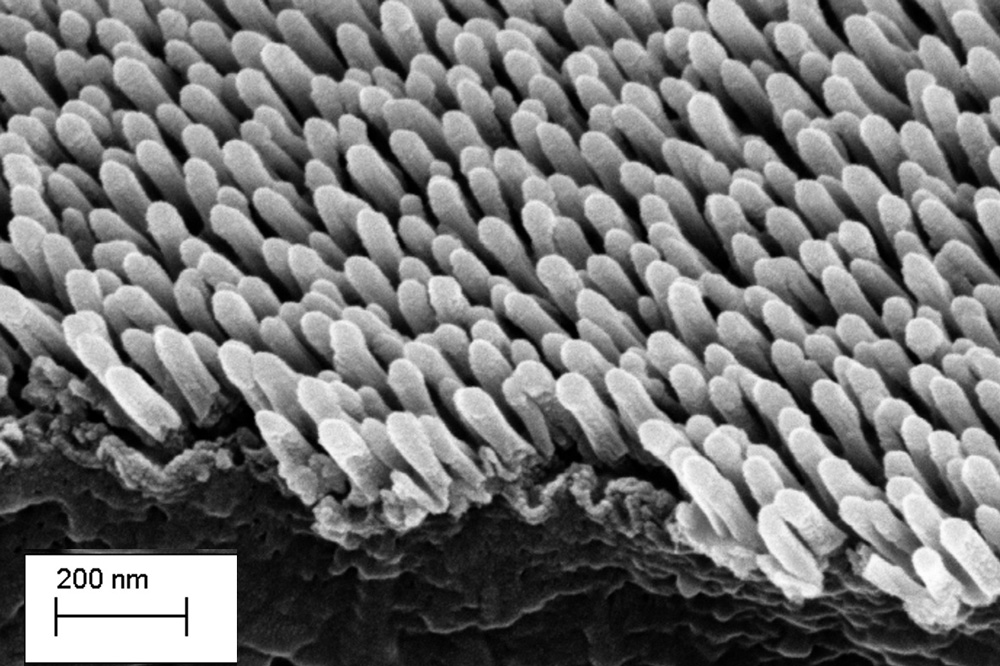

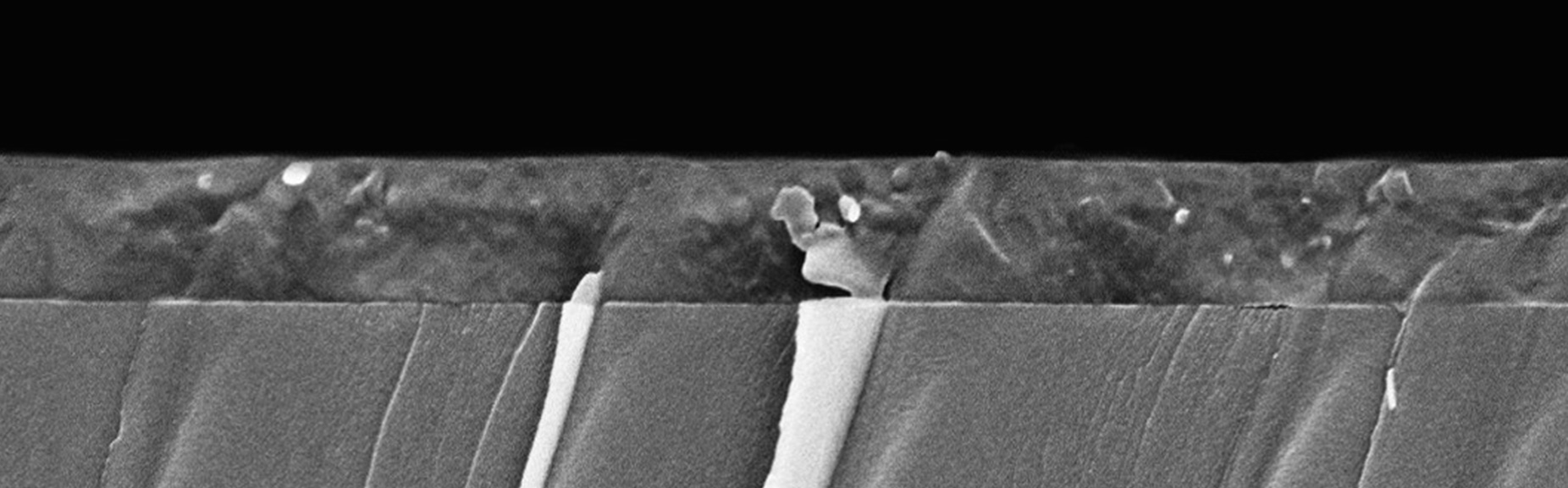

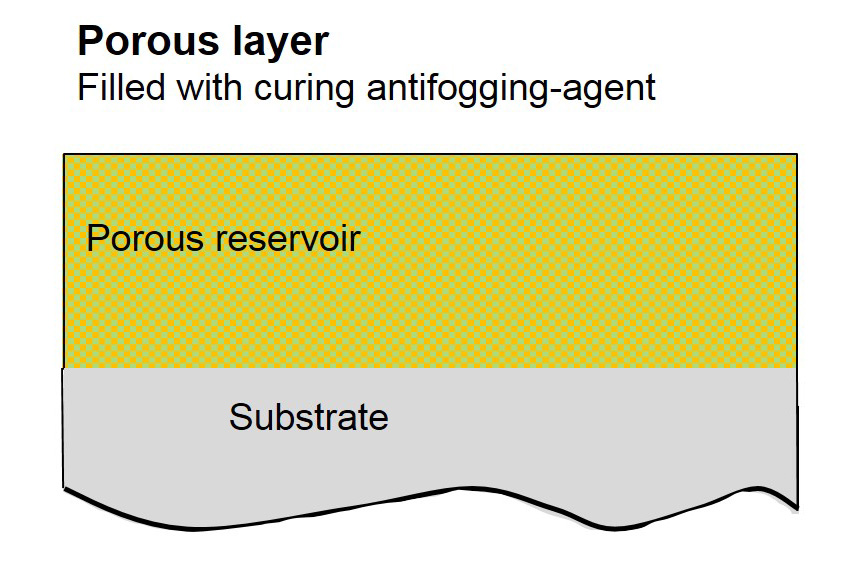

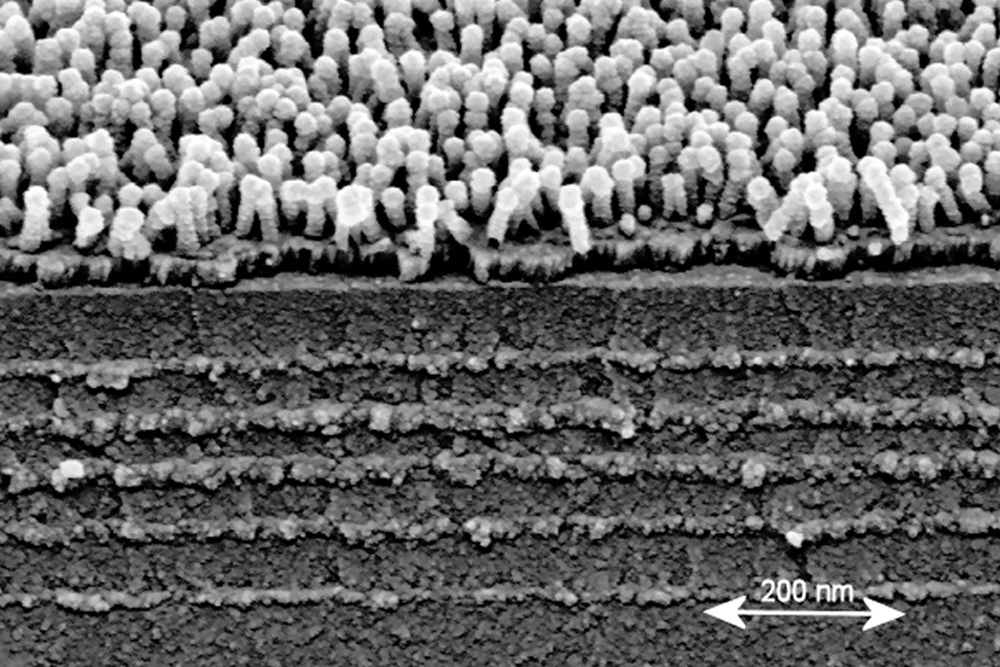

To protect the hydrophilic components, the organic compounds can also be incorporated in porous oxide layers. Such a reservoir-system can be obtained, for example, by co-evaporation of two materials (e. g. Al2O3/SiO2) followed by dissolving and removing one component. Alternatively, porous SiOx-layers produced by Combustion Chemical Vapor Deposition (CCVD) can be filled. For filling experiments, antifogging lacquers provided by the industrial partners and some alternative hydrophilic materials will be tested.

Eight industrial partners of various research areas such as ophthalmic lenses, automotive engineering and specialty chemicals collaborate for this current project of the European Society for Thin Films (EFDS) supported by the Industrial Research Associations (grant number: 18778 BR).