Objective

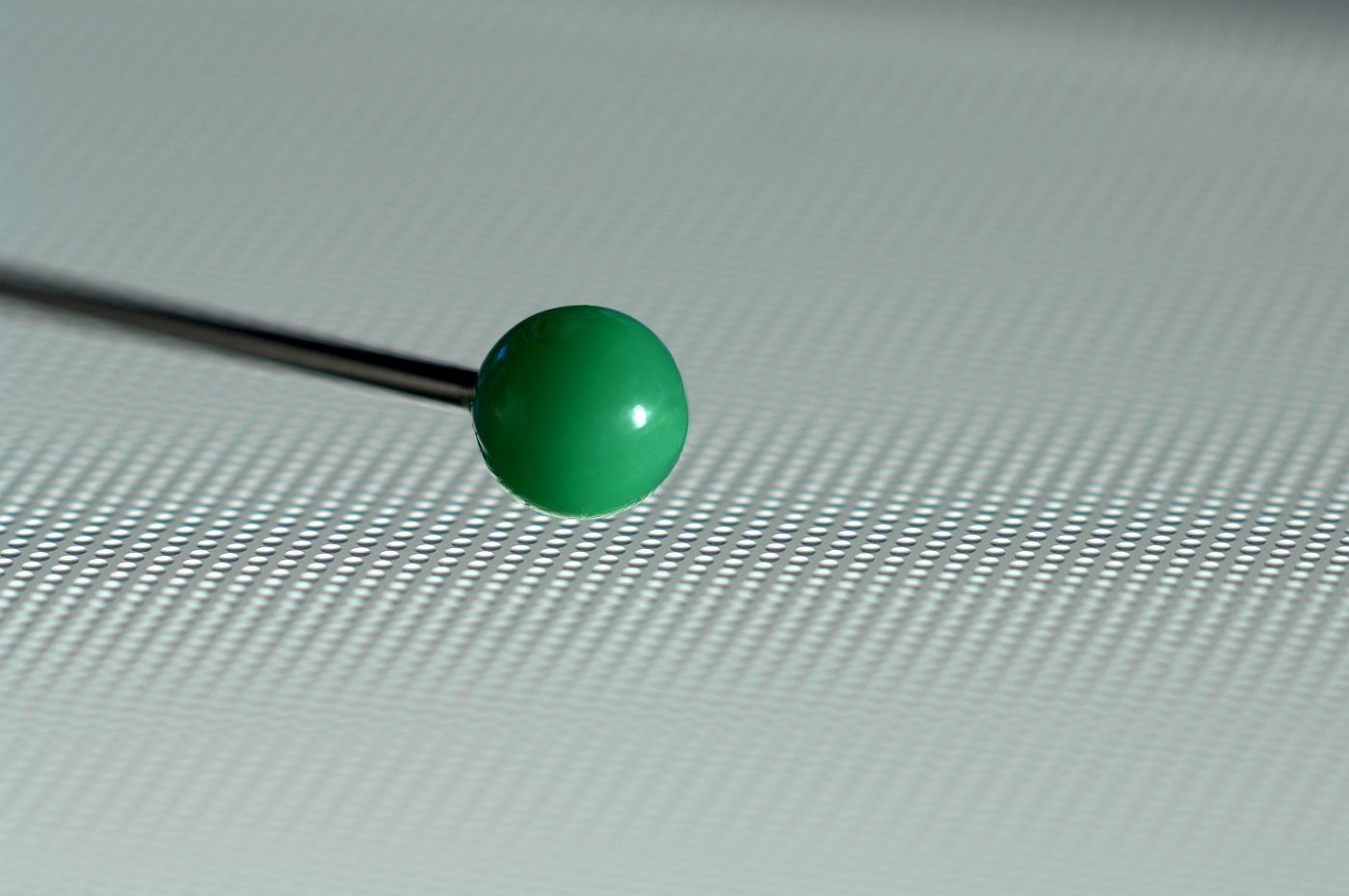

Fabrication of micro-optical elements with high durability, high laser damage threshold and transparency ranging from UV to IR in fused silica, borosilicate glass and silicon.

Technology

- Wafer-scale process technology on silicon, fused silica or borosilicate glass

- Primary pattern generation by lithography and polymer reflow or variable dose laser lithography

- Proportional transfer by plasma dry etching (RIE, ICP)

- Double-sided aligned processing

- Surface AR-Coatings

- Separation by chip dicing

Characteristics

- Spherical and cylindrical lenses

- Diffractive elements

- Arrays with sub-μm position accuracy

- Aspherical lens profiles

- Lens sag: up to approx. 50 μm

- Uniformity: ±2 % on 100 mm wafer

- Reproducibility: ±2 %

- rms profile accuracy: ±0.3 % of lens height within 95 % of lens diameter

- Base material: Wafer Ø 100/150 mm, up to ca. 6 mm thickness

Applications

- UV, VIS and IR-optics

- Laser / fiber collimation

- Beam forming elements

- Homogenization

- Fill factor enhancement of detector arrays