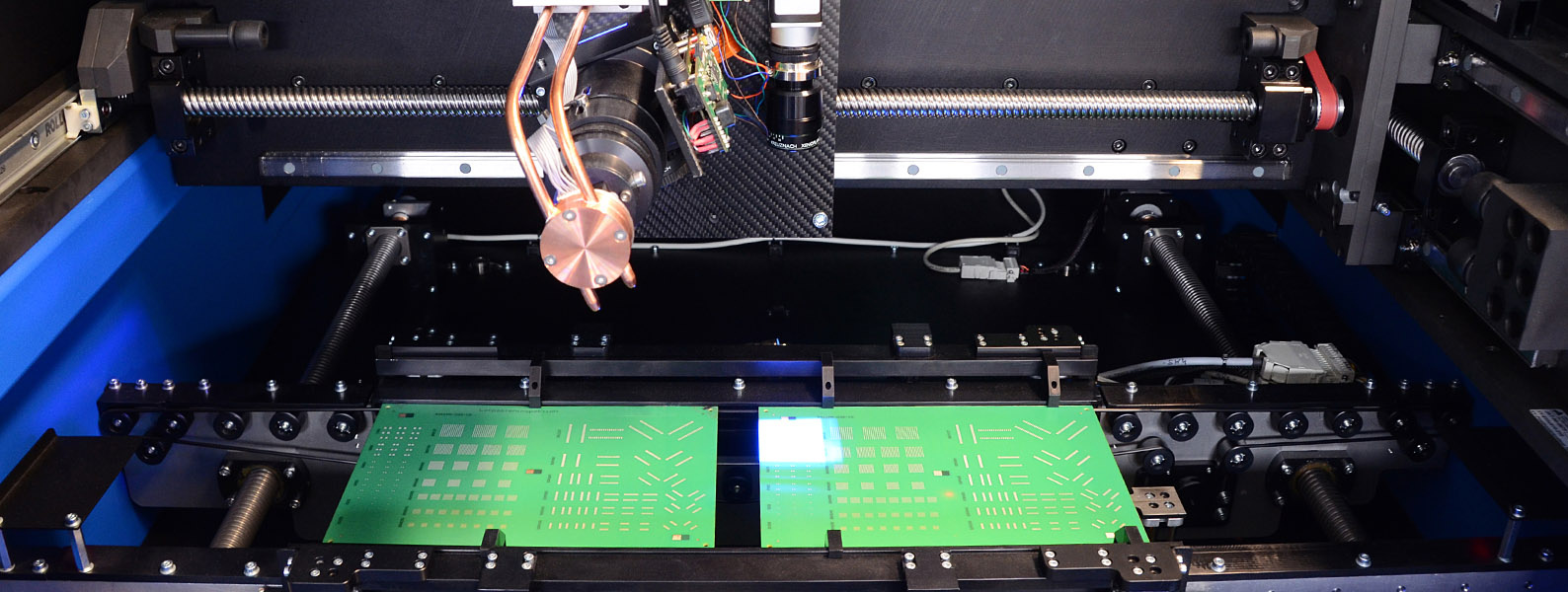

Measurement Principle

- Non-contact 3D metrology

- Simultaneous fringe projection and image acquisition

- Time-optimized computation of phase values and 3D coordinates using known system geometry parameters

- Parallelized 3D algorithms to utilize multi processor systems

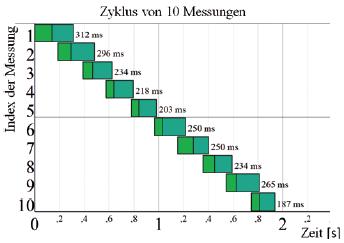

Permanent measurement cycle

Duty cycle:

- 0.18 s

Measurement speed:

- 80 cm2/s

- 22.2 Mio. pixel/s

Our Offer

- In-line inspection of industrial products with high precision

- Measurement systems for application at assembly-line

- Continuous measurement with respect to the specifications for effective evaluation and processing

- Implementation of sensors in automated inspection systems

- Possibility of remote diagnostic and automated recalibration

System Parameters

Measurement point pitch:

- 20 µm

- 15 µm

- 10 µm

Camera:

- 4 Mio. pixel

Single measurement field:

- 40 mm x 40 mm

- 30 mm x 30 mm

- 20 mm x 20 mm

Measurement uncertainty:

- 5 µm ... 10 µm