Oberkochen, Ditzingen, Jena

ZEISS, TRUMPF and Fraunhofer research team awarded the Deutscher Zukunftspreis 2020 for the development of EUV lithography

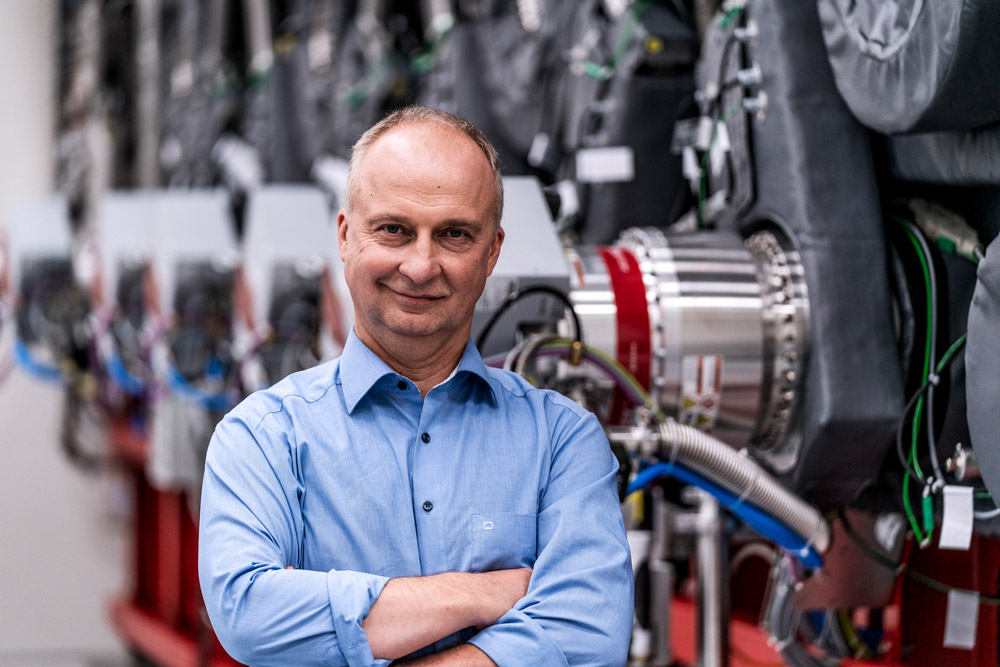

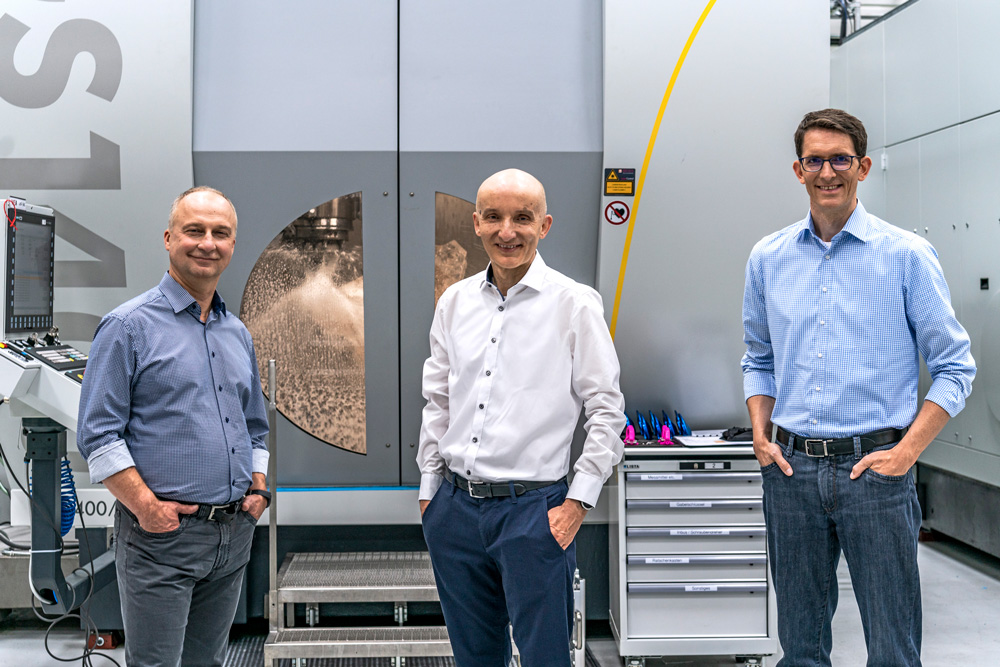

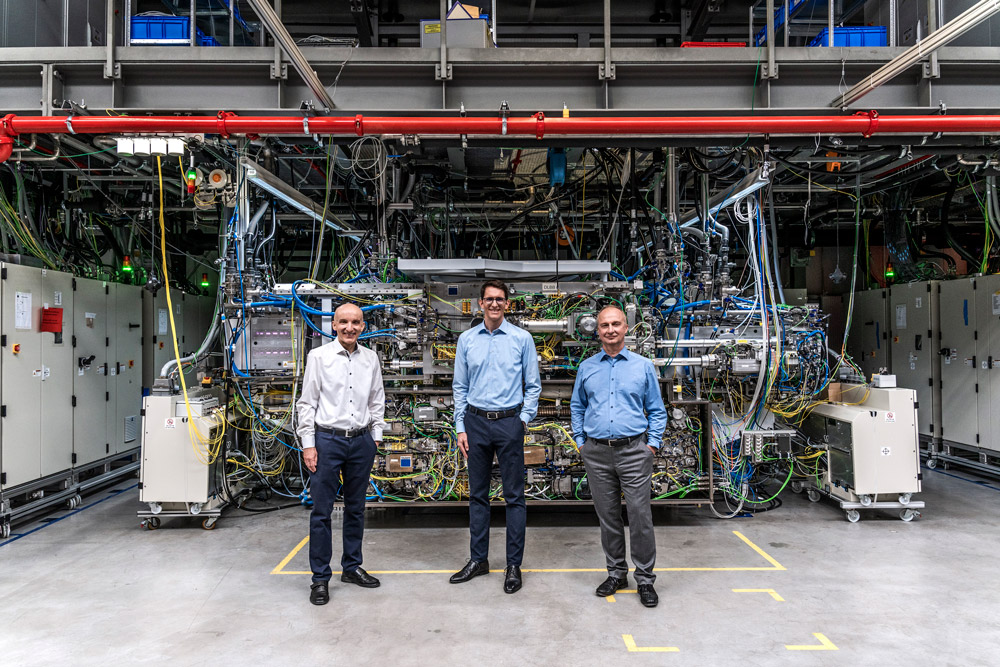

The Federal President Frank-Walter Steinmeier announced the winners of the Deutscher Zukunftspreis 2020 (German Future Prize 2020) in a ceremony in Berlin on November 25, 2020. The Federal President honored the team made up of Dr. Peter Kürz from the ZEISS Semiconductor Manufacturing Technology (SMT) segment, Dr. Michael Kösters from TRUMPF Lasersystems for Semiconductor Manufacturing, and Dr. Sergiy Yulin from the Fraunhofer Institute for Applied Optics and Precision Engineering IOF in Jena, bestowing on them his technology and innovation award for their project titled "EUV Lithography – New Light for the Digital Age".

- EUV lithography enables chips for state-of-the-art smartphones and automated driving

- World-leading manufacturing technology strengthens German-European position in global semiconductor business

Successful market launch creates jobs

The winning team made a significant contribution to developing EUV technology and preparing it for industrial series production. The result? A future-proof technology backed by more than 2,000 patents which forms the basis for the digitalization of our daily lives and enables applications such as automated driving, 5G, Artificial Intelligence and other future innovations. Thanks to EUV, over 3,300 high-tech jobs have been created at ZEISS and TRUMPF to date and an annual turnover of more than one billion euros - with an upward trend - was generated in 2019.

Higher-performance and more energy-efficient and cost-effective microchips

The Dutch company ASML is the world's only EUV lithography machine manufacturer. As an integrator, the company designed the overall system architecture and the EUV source in particular. The high-power laser from TRUMPF for the EUV light source and the optical system from ZEISS are key components of these machines. EUV stands for "extreme ultraviolet" light, i.e. light with an extremely short wavelength. This unrivalled key technology can be used to produce significantly higher-performance and more energy-efficient and cost-effective microchips than ever before in this decade and the next. Effective digitalization requires a continued and rapid increase in computing power. Today's smartphones are a million times more powerful than the computer used during the first Moon landing back in 1969. This is made possible by a microchip that is smaller than a fingertip, but which has the capacity to accommodate more than fifteen billion transistors.

The manufacturing process for the latest chip generations is based on the use of EUV light, pushing the limits of what is technology feasible. From the light source and the optical system in a vacuum through the surface coating of the mirrors used in the process - practically the entire exposure technology had to be developed from scratch.

EUV lithography - a German-European success story

"Heartfelt congratulations to our winning team, representing thousands of EUV developers. We and our partners are very pleased to receive this award from the German President, which recognizes an enormously labor-intensive development effort and its translation into a technology that is dominating the global market," says Dr. Markus Weber, ZEISS Group Executive Board member and head of the Semiconductor Manufacturing Technology segment. "ZEISS stands for optical excellence and precision. This has always been a key factor in chip production. As a breakthrough innovation, EUV technology continues to enable major advances in digitization in business and society. We are proud to contribute to this in together with our strategic partners ASML, TRUMPF, and Fraunhofer".

TRUMPF Vice Chairman of the Group Management Board and Chief Technology Officer Peter Leibinger: "We are very pleased that Dr. Michael Kösters, Dr. Peter Kürz and Dr. Sergiy Yulin from TRUMPF, ZEISS, and the Fraunhofer IOF have won the Deutscher Zukunftspreis 2020. By combining inventiveness, an understanding of technology, perseverance and good teamwork, they are a perfect example of how future technologies can be developed to industrial maturity through strong partnerships. The award shows us once again that a strong industry and an outstanding research landscape play a crucial role in meeting the challenges of this century. The mammoth EUV lithography project is also creating jobs during the Corona year while additionally ensuring that Europe plays a pioneering role in the production of state-of-the-art microchips".

With the world's strongest pulsed industrial laser, TRUMPF supplies a key component for the exposure of the most modern microchips used in every modern smartphone. There is no economical alternative to this laser for generating the light required for EUV lithography.

The quality and form of the illumination system and the resolving power of the projection optics from ZEISS determine how small the structures on microchips can be. The mirrors used in the optical system therefore contain significant innovations. Since even the smallest irregularities lead to imaging errors, the world's "most precise" mirror was developed for EUV lithography. Fraunhofer was an important research partner in the sophisticated coating technology for the large-scale mirrors.

"We congratulate the researchers from ZEISS, TRUMPF, and the Fraunhofer IOF on this great award for their excellent work. In EUV lithography, they have developed a technology that will provide a digitalization push globally and by so doing also lays the foundation for further innovations," says Prof. Reimund Neugebauer, President of the Fraunhofer-Gesellschaft. "Fraunhofer scientists played a major role in the development of the first EUV mirrors and beam sources in the almost three decades of research. The fact that EUV lithography is now being applied is also thanks to the intensive cooperation between science and industry as well as the spirit of research and the enduring commitment of all involved".

Honor for innovative achievements in engineering and the life sciences

The German Future Prize has been presented every year since 1997. It is one of the highest accolades for scientific achievement in Germany and is worth 250,000 euros. It honors exceptional achievements in technology, engineering and the life sciences that have resulted in viable products. Every year, during a multistage selection process, the prestigious jury selects three research teams and their innovation for the final round from among a large number of different projects, the "shortlist". Alongside their innovative achievements, the jury also evaluates the development's economic and social potential. For Fraunhofer, this is the 9th award of the "Deutsche Zukunftspreis". Of these, the prize went to Fraunhofer IOF for the third time. This year's prize was presented in Berlin on November 25, 2020 under pandemic restrictions at Verti Music Hall by Federal President Frank-Walter Steinmeier.