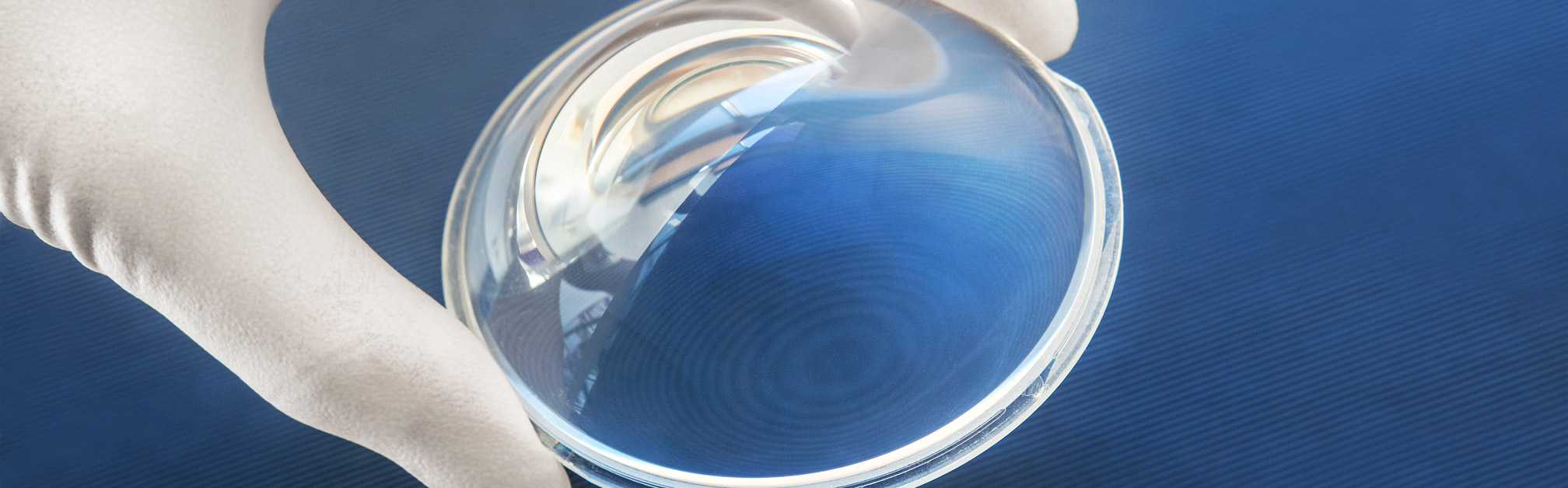

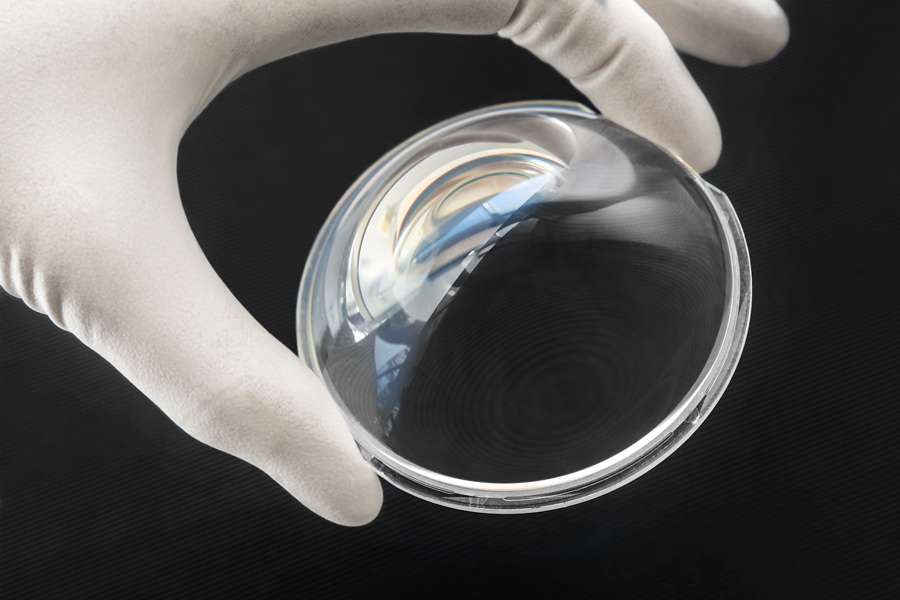

Antireflection Coating AR-plas2 for Glass- and Plastic Lenses

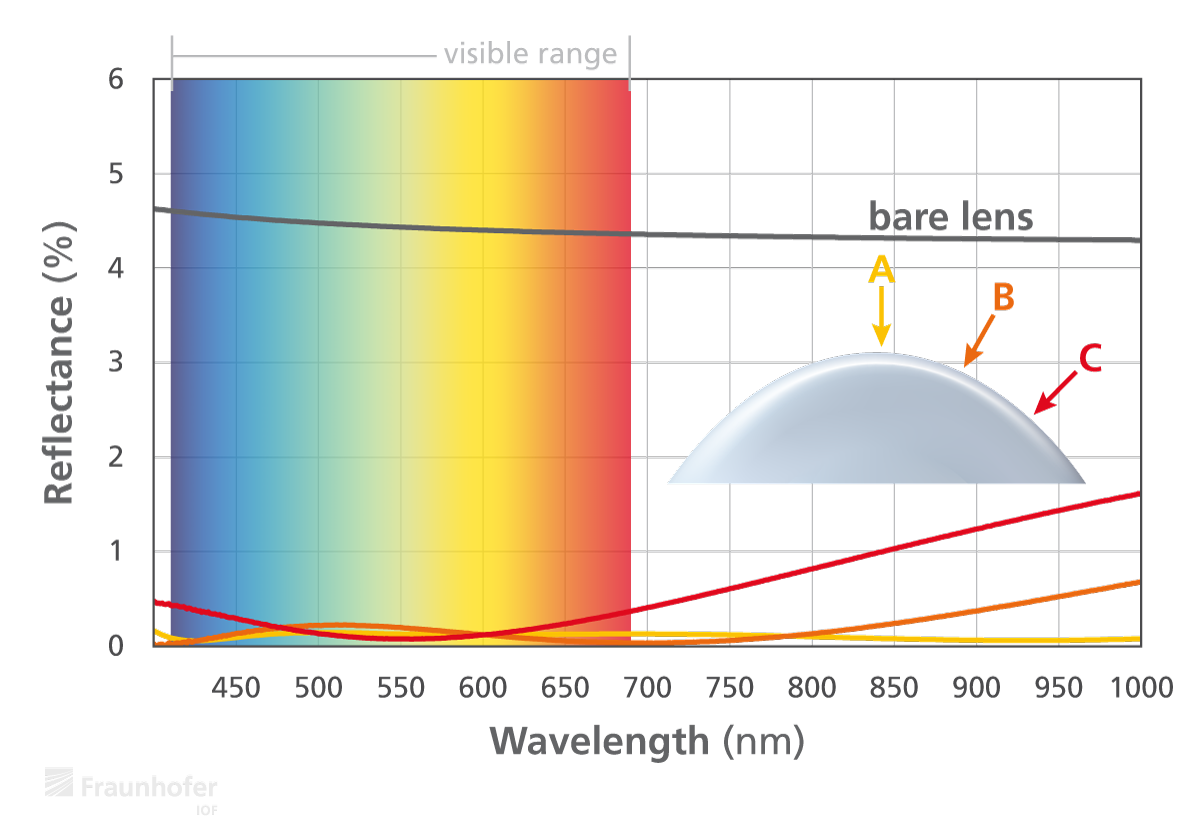

There is an increasing demand for high performance antireflection (AR) coatings applied to complexly shaped surfaces. The application of such coatings on strongly curved lenses remains a challenge, particularly when a wide range of light incidence angles is required. PVD deposition processes, commonly used in industry, are not suitable for conformal coating resulting in a shift to shorter wavelength of the antireflection band on inclined areas. Conformal coating deposition has recently been made possible at Fraunhofer IOF using Atomic Layer Deposition pilot plants. This technology is being developed for use in the optics industry; however, it can only partly solve the challenges.

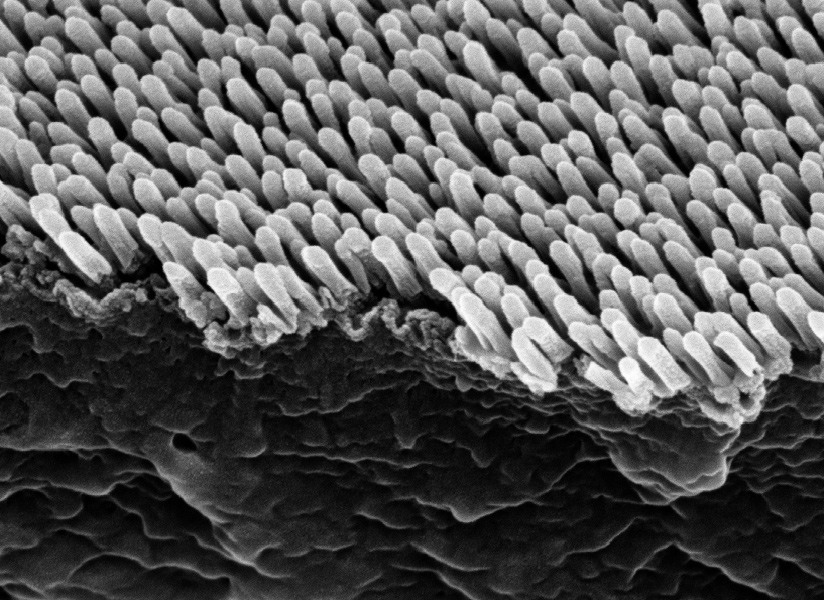

To achieve excellent antireflection properties over the full area of a curved lens with well-established evaporation technology, it is necessary to compensate the spectral shift by widening the AR bandwidth. The crucial factor for minimal remaining reflection is a low effective refractive index n < 1.15 for the final, nanostructured layer. At the same time, requirements for high angles of light incidence can be achieved more easily than before.