Objective

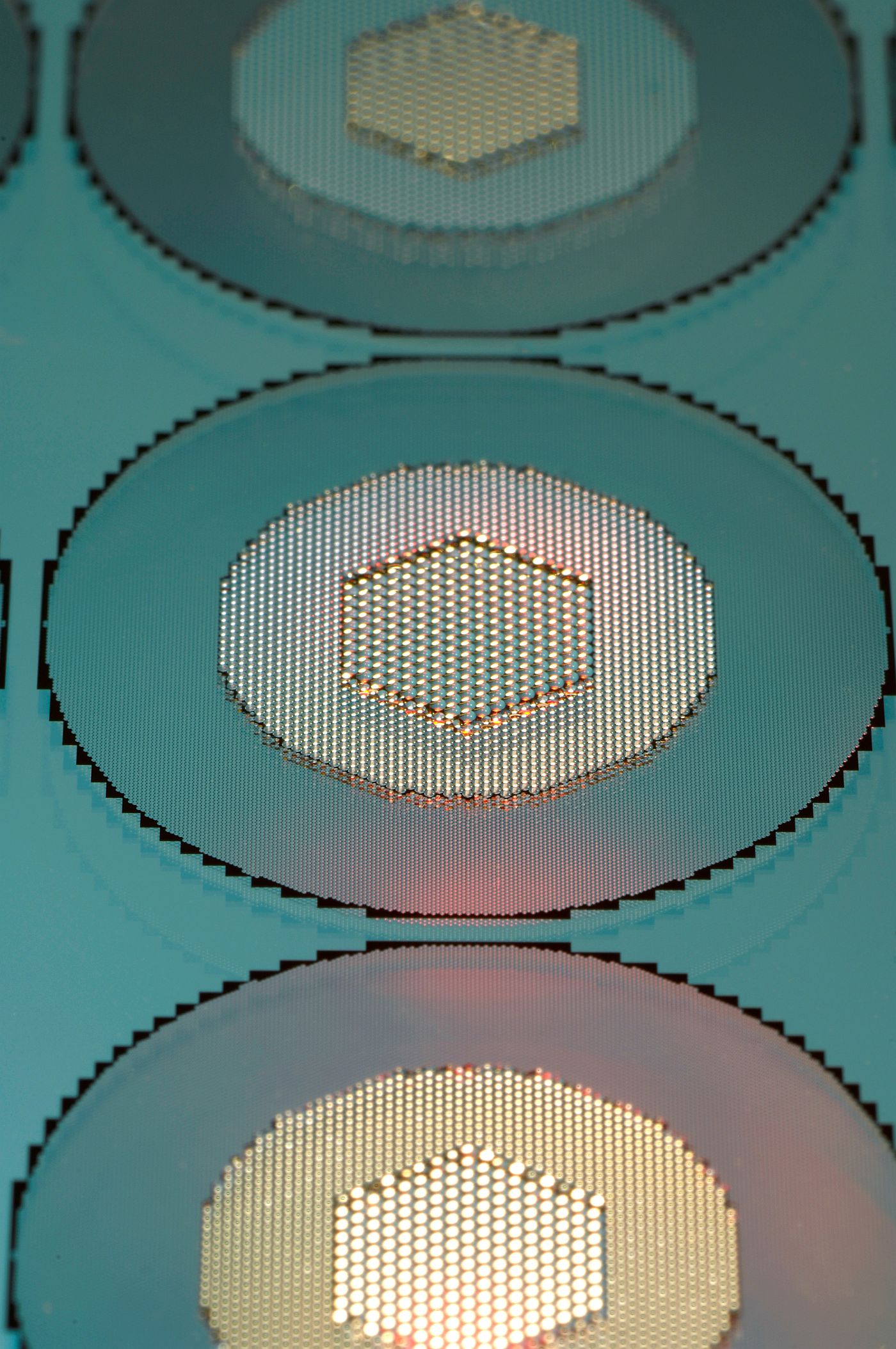

Reproducible fabrication of refractive microlenses with parameters derived from system design calculations.

Technology

- Mastering by direct-writing grayscale lithography or binary mask lithography and reflow

- Replication by UV polymer molding or

- Transfer to silicon, glass or fused silica by reactive ion etching

- AR-coating, dicing

- Integration of aperture- / filter structures

- Double-sided patterning (tandem arrays)

Geometry of the lens arrays

- Spherical, cylindrical or elliptical lenslets; sag up to 100 μm

- Layout and focal length varying across the array / wafer („Chirp”)

- Lens diameter: 5 μm – 3000 μm

- Resolution / lens gap: 1 μm

- High fill factor, lateral precision

- Homogeneity of focal lengths: ±1 % across wafer

- Generation of aspheres by reactive ion etching (RIE)

- 100% fill factor of arrays by RIE assisted mastering

Replication by UV molding

- As thin polymer layer on glass, Si, etc.

- High lateral and axial precision

- High chemical / thermal stability

- On top of processed wafers (CMOS, VCSEL)

Applications

- Laser / fiber collimation

- Beam forming elements, homogenizer

- Fill factor enhancement on detector arrays

- Field-of-view matching for displays

- Miniaturized imaging systems, sensors