Motivation

Aspheres and optical freeforms are more and more important applications for space and astronomy. Mirror based telescopes are suitable for multi spectral imaging in the range from IR to UV; applications in the VIS or UV spectral range require an ultra-smooth surface in terms of figure and roughness.

Technologies

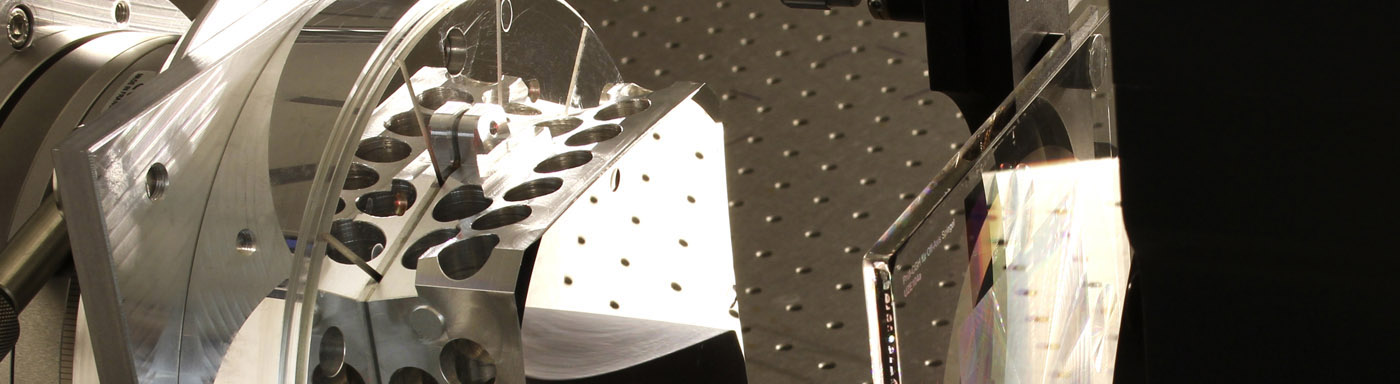

Ultra-precision machining with diamond tools, in combination with polishing and figuring techniques, enables the manufacturing of high quality mirrors with various surface shapes in space certified materials. Highly sensitive interferometric metrology using Computer Generated Holograms (CGH) or tactile measurement techniques allows correction cycles to reduce form errors.

For applications in the VIS or UV spectral range, post-polishing and post-figuring processes like ion beam figuring (IBF) and magneto rheological finishing (MRF) are applied on an amorphous nickel-phosphorous (NiP) coating on the CTE-matched mirror substrate. Additionally, reflection and protection layers can be deposited.

Results

Aspherical mirror (190 mm x 250 mm)

- Al-6061, NiP-coated, protected Ag

- SPDT, post-polishing, IBF-figuring

- Micro roughness (WLI 50x): < 1 nm (rms)

- Shape irregularity: < 14 nm (rms); 110 nm (p-v)

Freeform mirror (Ø 320 mm)

- AlSi-alloy, NiP-coated

- SPDT, MRF-figuring, post-polishing

- Micro roughness (WLI 50x):

< 3 nm (rms) after MRF

< 0.8 nm (rms) after polishing

- Shape irregularity: < 16 nm (rms); 120 nm (p-v)