Cooperation with the Fraunhofer IOF

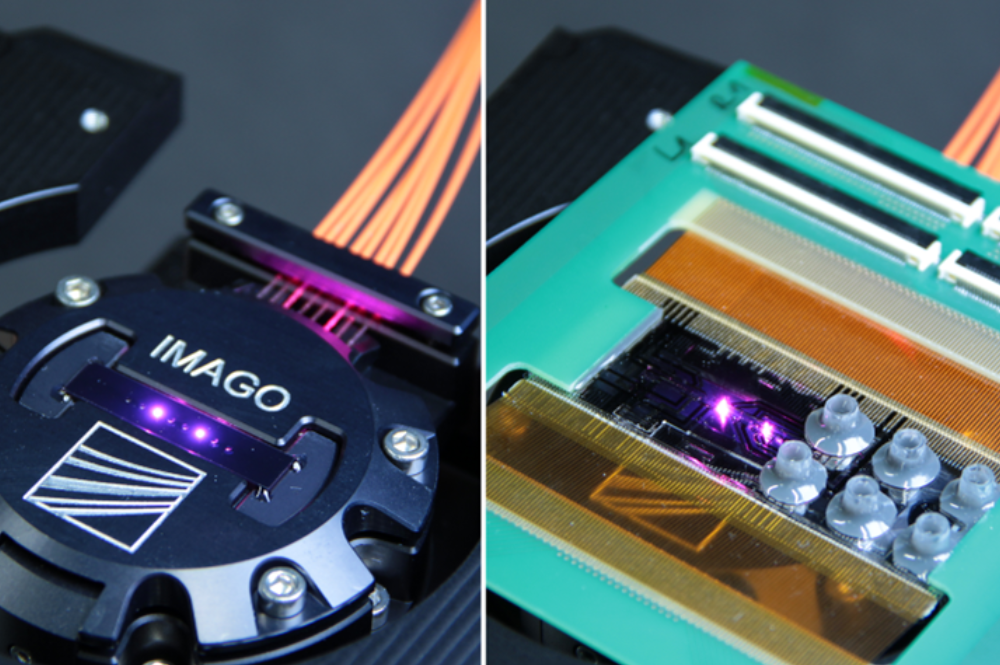

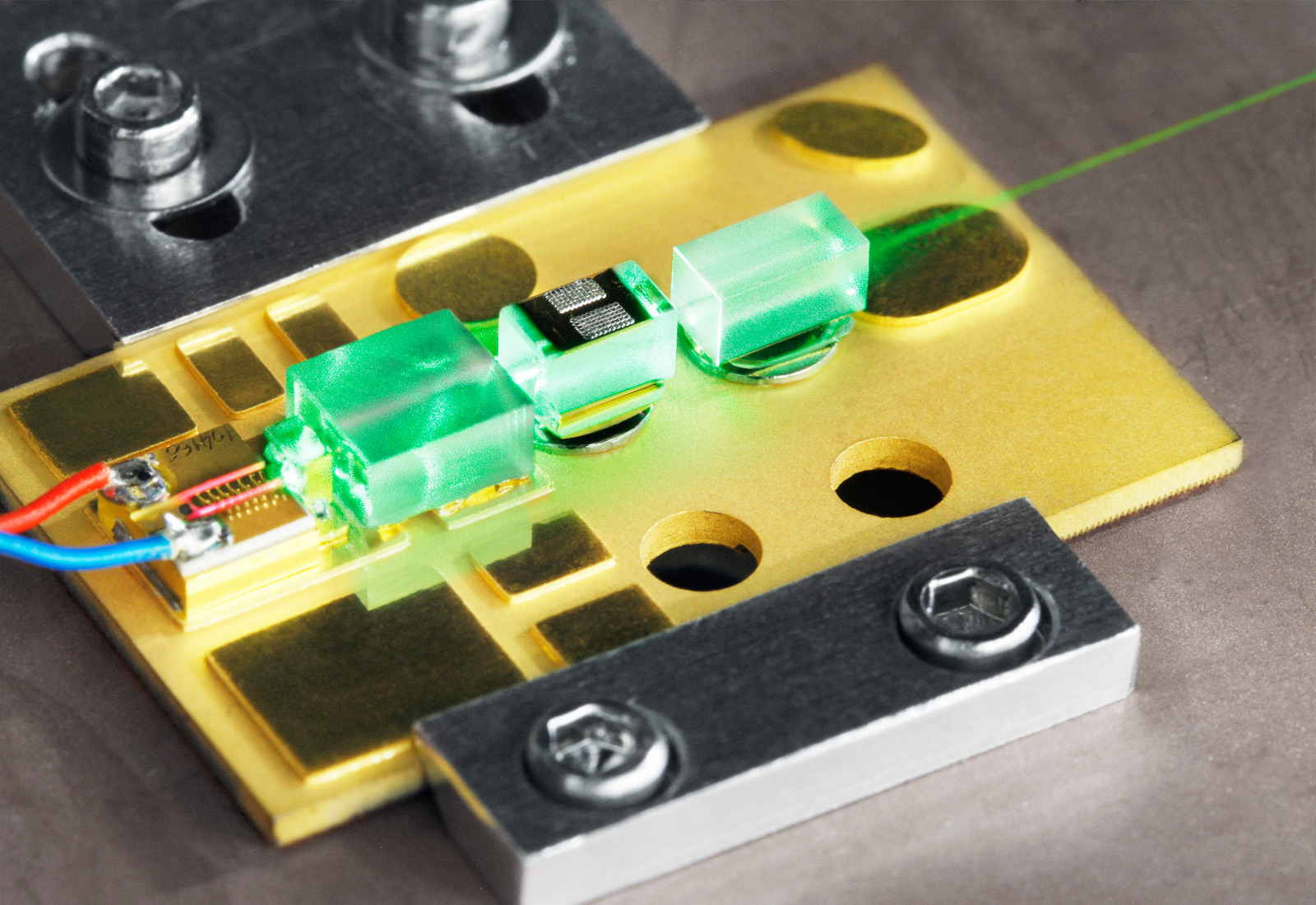

The Fraunhofer Institute for Applied Optics and Precision Engineering IOF develops solutions with light - from its generation and manipulation to its use as a sensor and tool. Depending on the order, we support our customers along the entire process chain or in individual process steps - from the design to the production of components, the assembly of opto-mechanical or opto-electronic systems to holistic characterization.

In close coordination, we support our customers on request from their initial questions through to market launch. We also take on the transfer of results and developments into the processes of our partners and customers in the form of personnel training or technology transfer.

In addition to contract research, we also offer individual services such as the functional coating of surfaces, material and component testing, ultra-precision machining of components, high-speed 3D measurements and the construction of customized components and special machines. In addition, the institute holds a large number of patents on optical technologies and developments, for which we offer various licensing models. We provide information on current technological trends and developments in individual training courses and workshop formats.

Further information on our services can be found on the corresponding technology pages.