Motivation

Micromachining provides a more flexible manufacturing of microparts with a much wider choise of materials. The manufacturing is done by using the classic cutting techniques of milling, drilling and turning, as well as microtools made of carbid or profiled diamond-tools. Production-oriented design of micro modules and appropriate selection of materials are the basis for mechanical manufacturing and structuring of small parts in high qualtity. Therefore microcutting permits a rapid way from the concept to the prototype.

Small parts for microassemby

- Assembly platforms, magazines

- Gripper for microprisms, microlenses, fibres

- Adjusting and assembly devices

- Mounts for microoptics

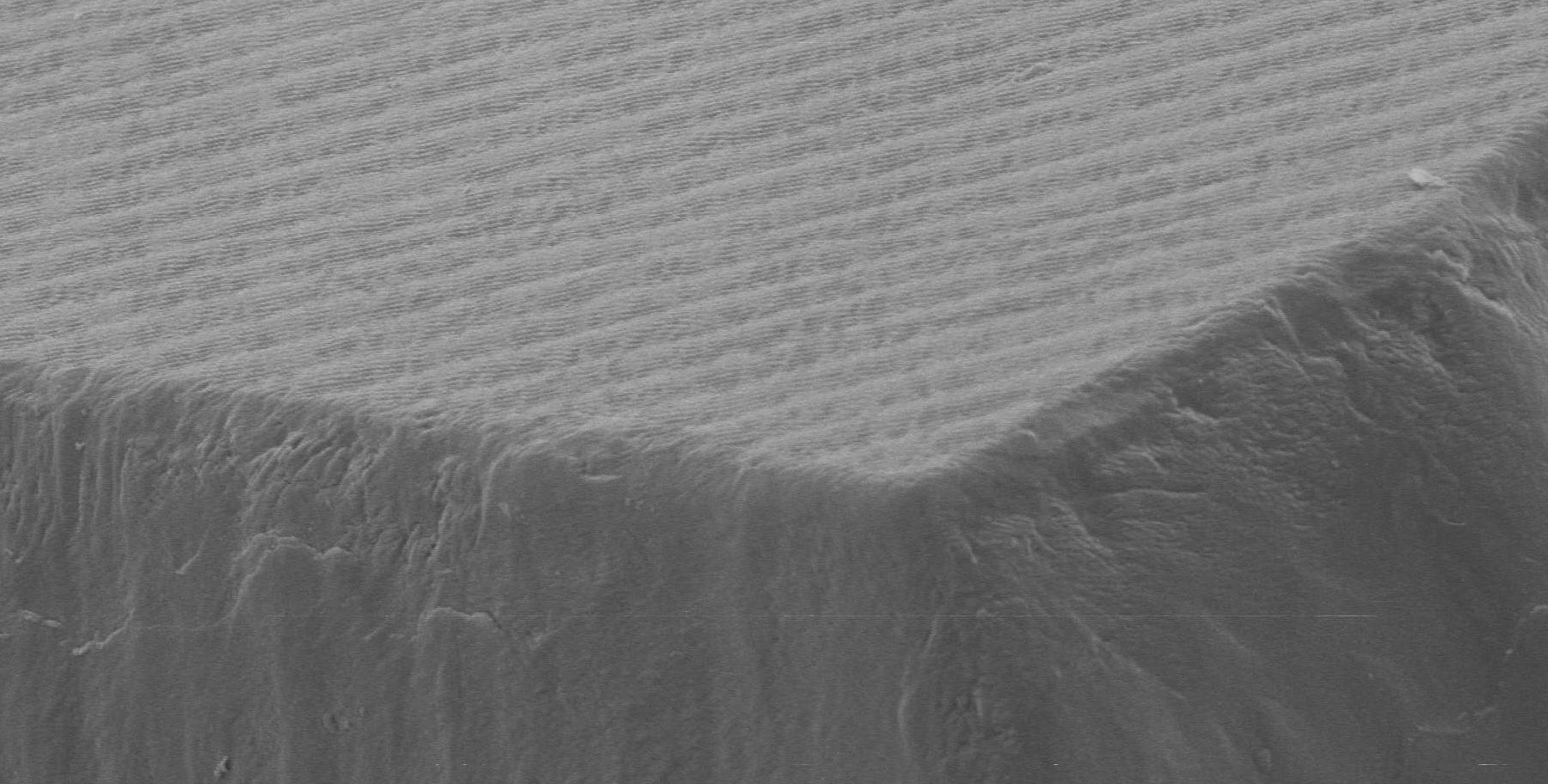

Microstructures made of machinable glass ceramic

- Microholes, holearrays (minimal diameter: 30 µm)

- Grooves, deepenings (minimal width: 100 µm)

- Free of burrs, stable

- Capable for vacuum environments, continuous use temperature: 800 °C

- Examples:

- hole structures to position and assemble optical fibres

- fluidic systems

- precisely structured coating masks