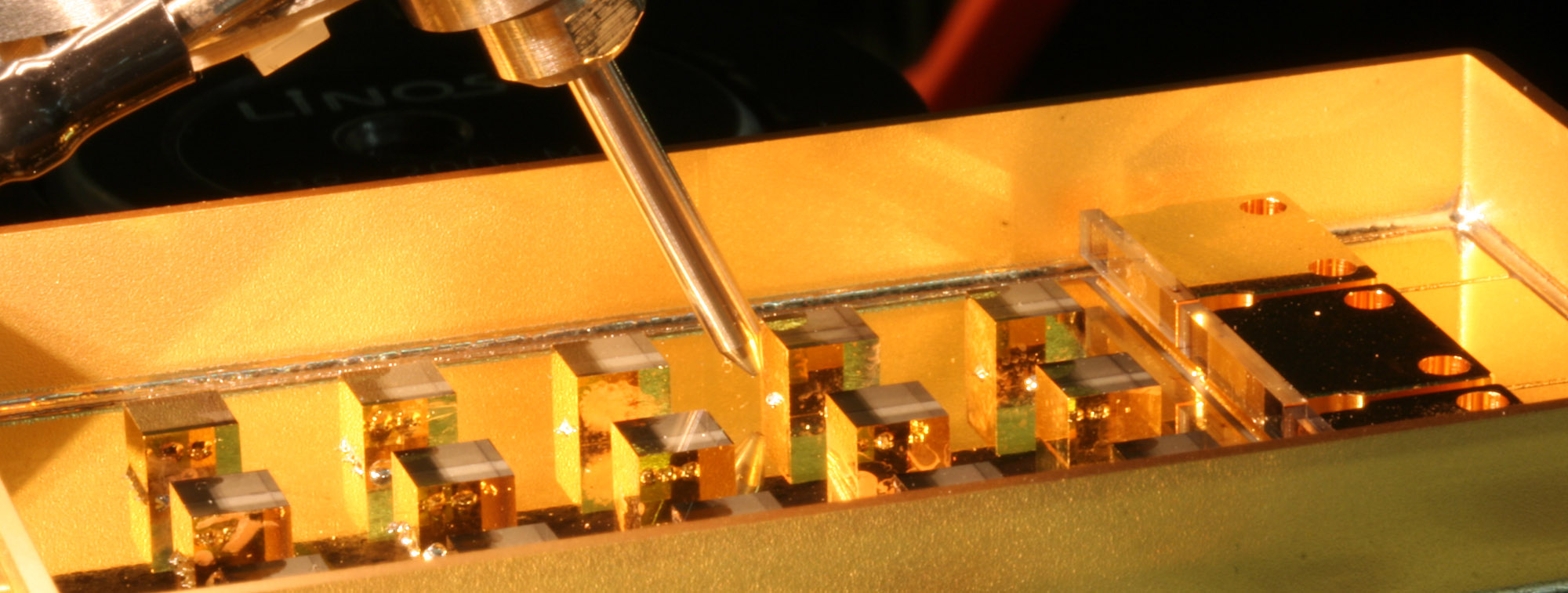

Handling of Microcomponents

For a mechanized or automated micro assembly one fundamental requirement is the development of handling procedures that are not only suitable for the precise gripping, positioning and aligning of small and often very sensitive components, but also able to work in production environments for a high numbers of assembled devices with similar, high quality.