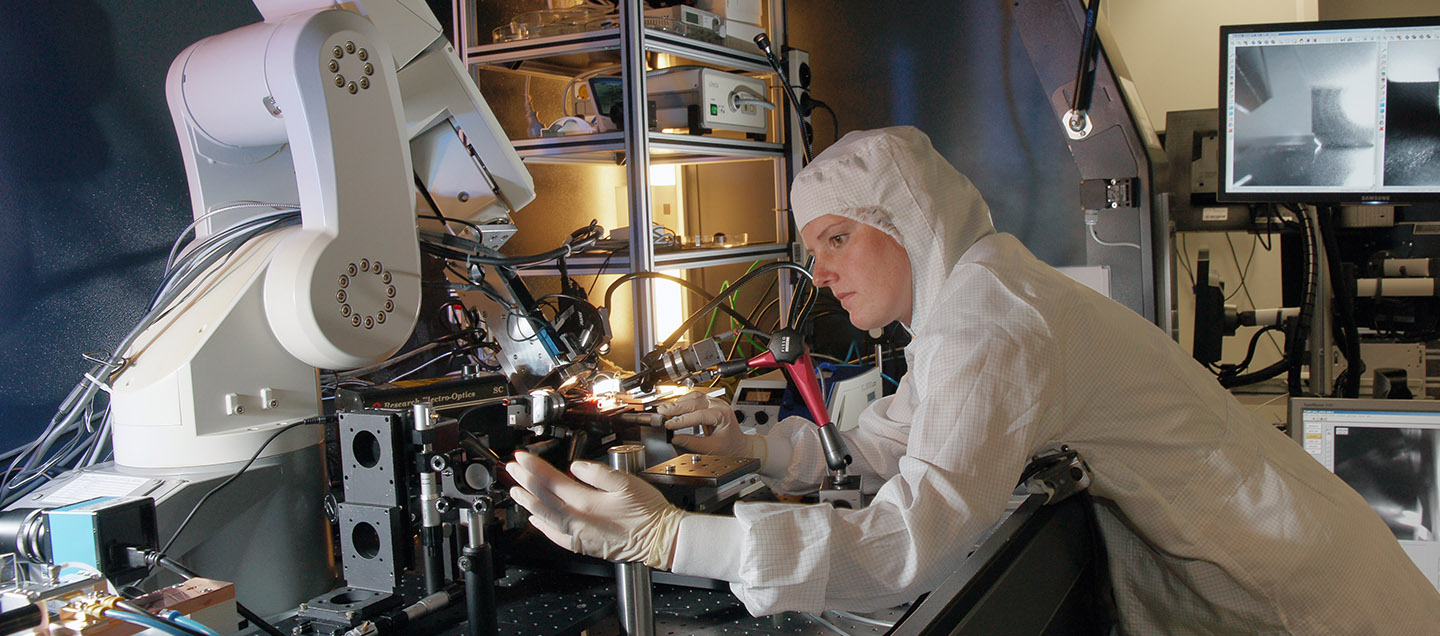

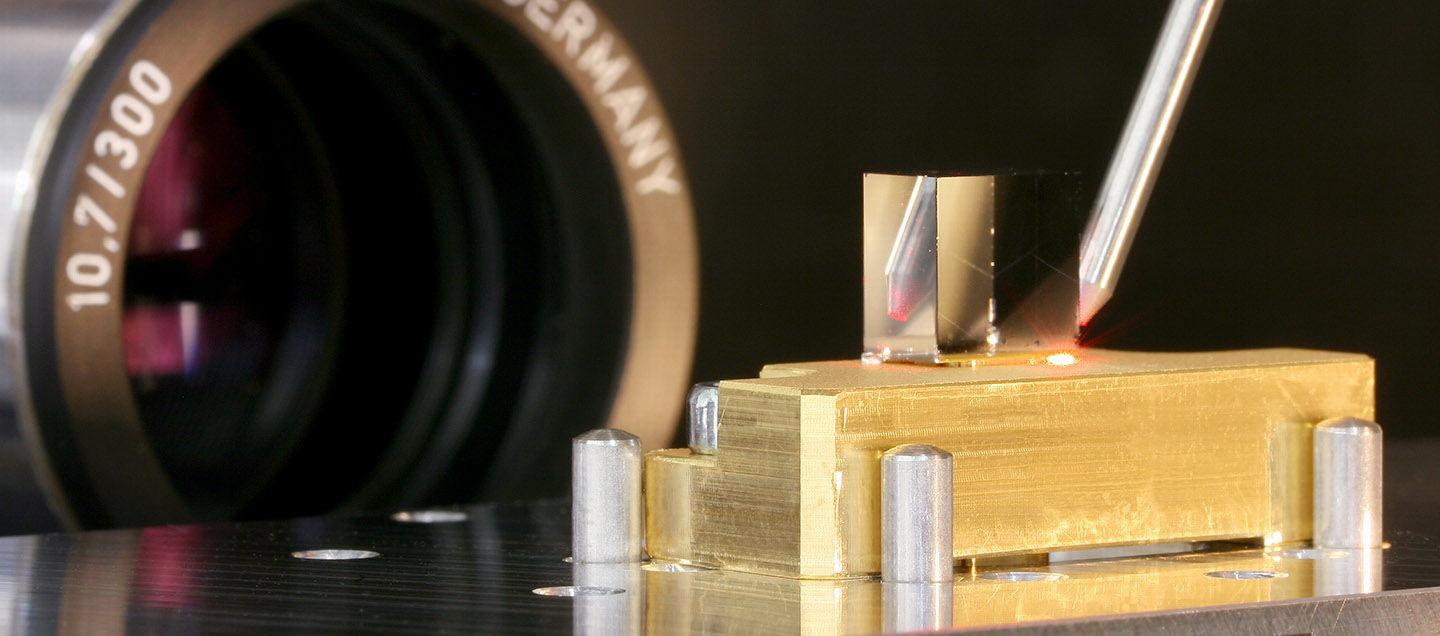

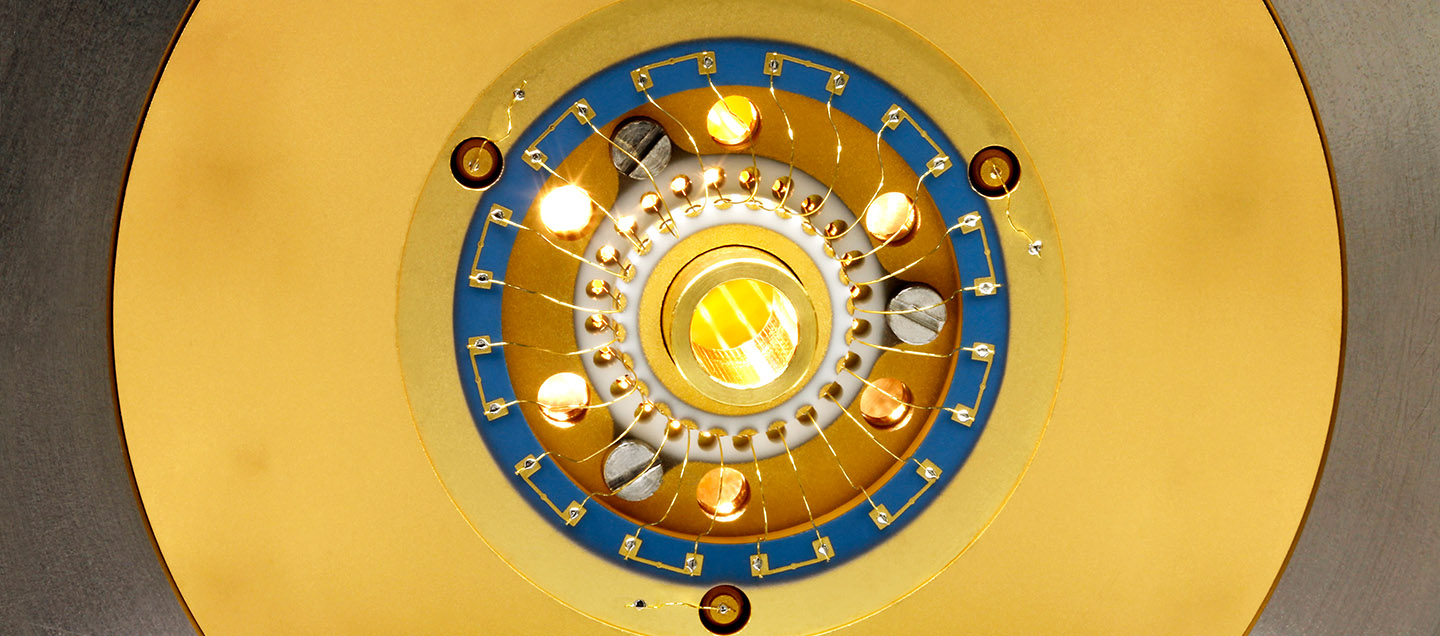

Fraunhofer IOF has extensive know-how in the development of technologies for hybrid integration of different components with the highest precision for the construction of complex opto-mechanical and opto-electronic micro and macro systems. This includes assembly technologies (positioning, adjustment), joining technologies (gluing, laser soldering, laser splicing), the printing of functional materials and structures, and much more. In addition, complex optical systems are integrated, even for extreme operating conditions, such as use under vacuum or space applications. Optical systems are featured increasingly by a high degree of complexity because the optical components have to be linked with electronic components and mechanical actuators to form systems with a high integration density.