Highly individualized micro- and macro-optical components and systems

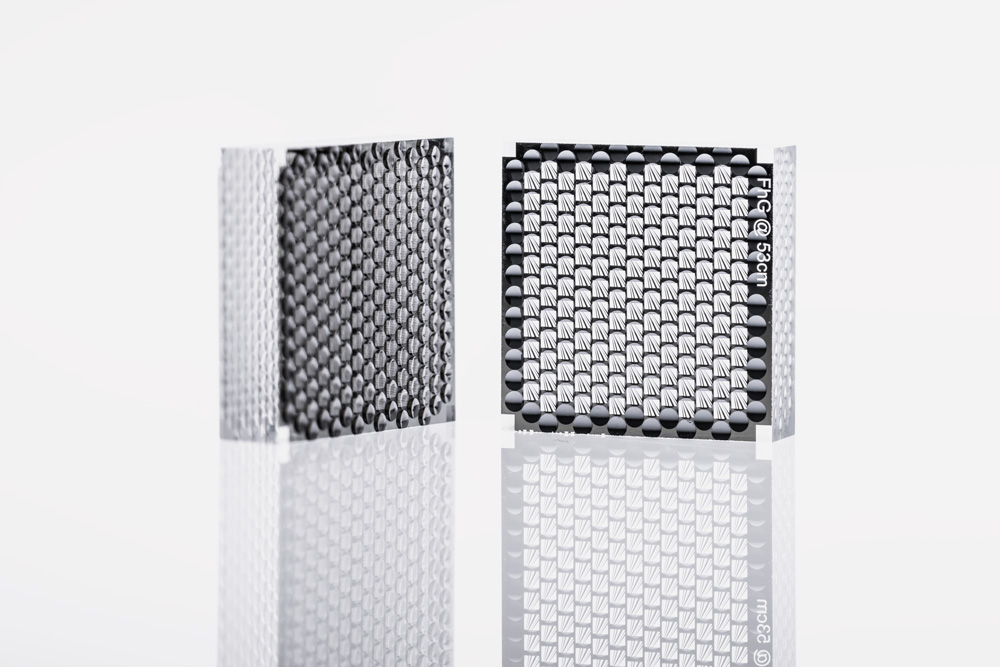

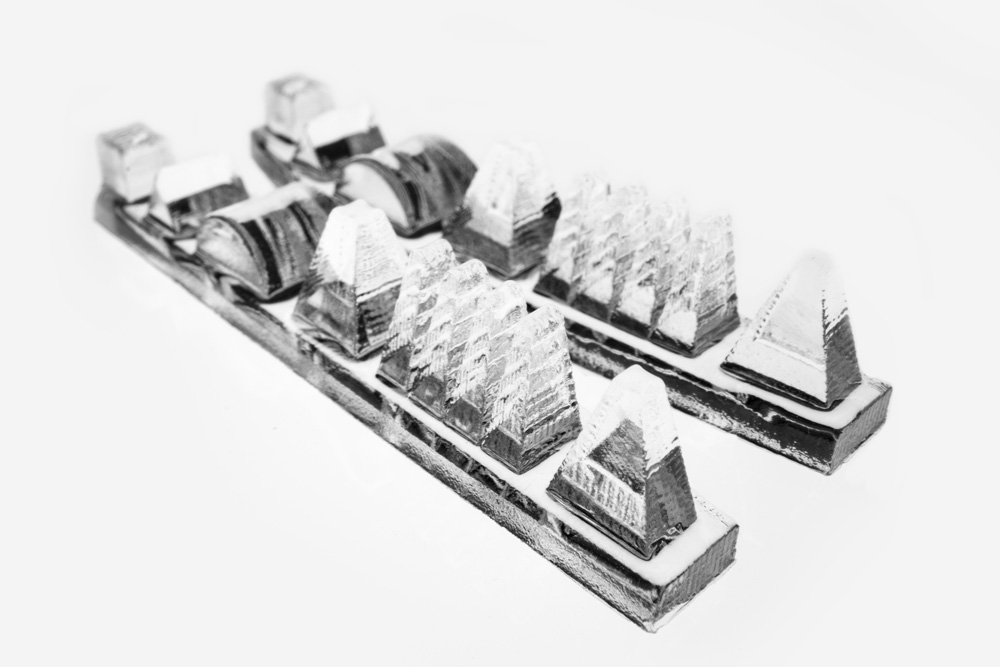

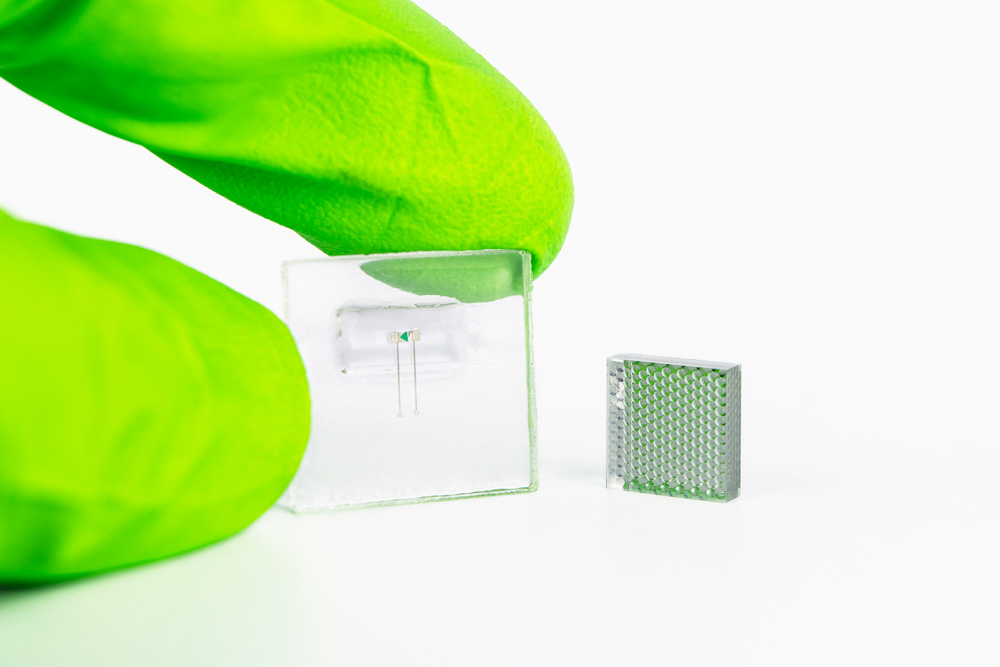

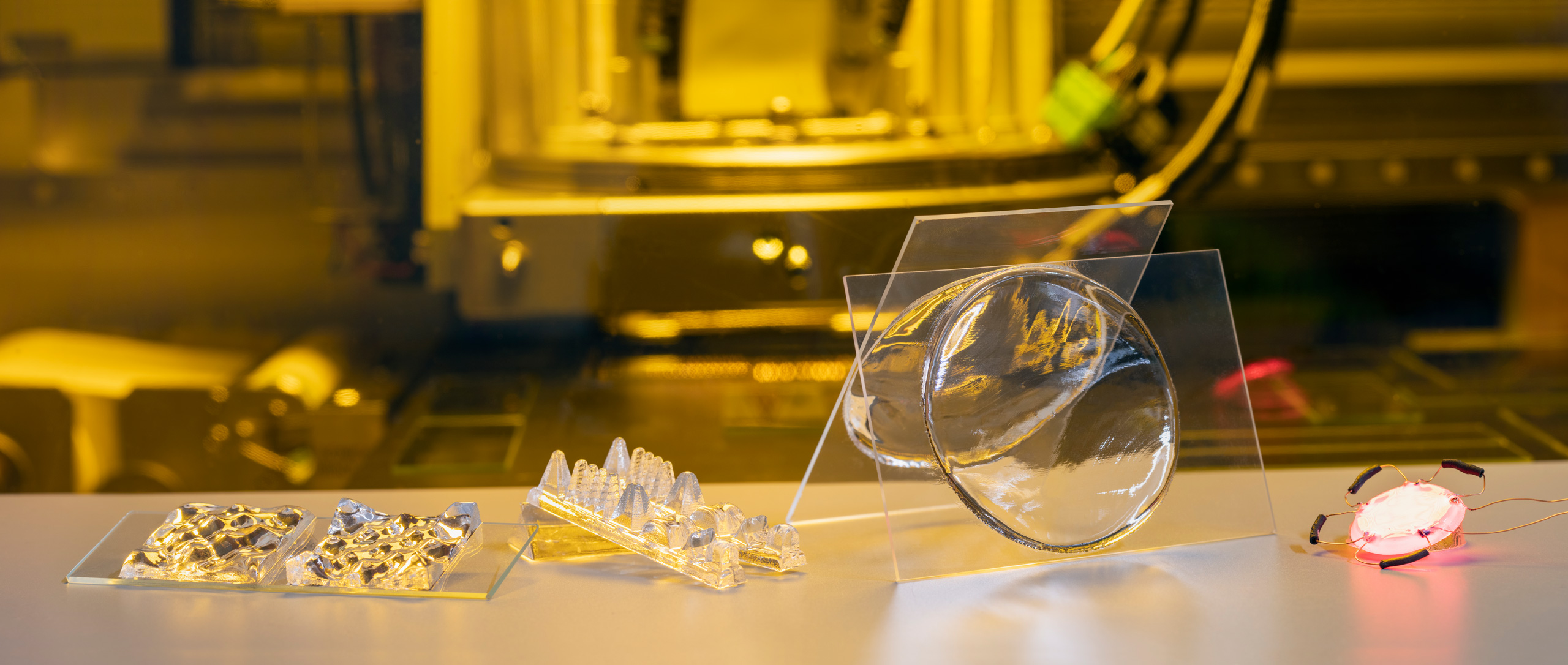

Additively manufactured micro- and macro-optics and optical systems open up new possibilities in development processes such as rapid prototyping or in the production of individualized small series. With 3D inkjet printing of optical elements, Fraunhofer IOF is developing solutions for the optics production of the future. The additive process not only enables the cost-effective production of individualized optical components. The compatibility of the process with numerous functional materials also opens up new possibilities in the production of highly integrated optical systems.

At Fraunhofer IOF, the entire process chain is investigated and developed, from the pre-treatment of the substrates and the development of the printing process, to the targeted post-treatment of the printed structures. Our many years of experience lead to a targeted parameter optimization of the entire printing process.

Our range of services

We realize tailor-made solutions for our customers with the development of single processes and process chains in the field of 3D printing of optical systems. Our range of services includes the selection of suitable materials and the development of inks, the development of targeted substrate preparation processes, the development of printing processes for the various materials and inks, as well as the targeted post-treatment of printed structures. In addition, extensive optical, electrical, and mechanical characterization of the printed structures is carried out at the customer's request.