Applications for metal optics include scientific instrumentations for earth observation, scan mirrors for laser material processing, or high power tools e.g. for EUV-lithography. The commonly used subtractive approaches are subject to severe limitations regarding the design of those mirrors. Additive Manufacturing (AM) of metal optics using selective laser melting is used to realize optimized mirror bodies. The layer wise built up of parts by AM is able to avoid these limitations.

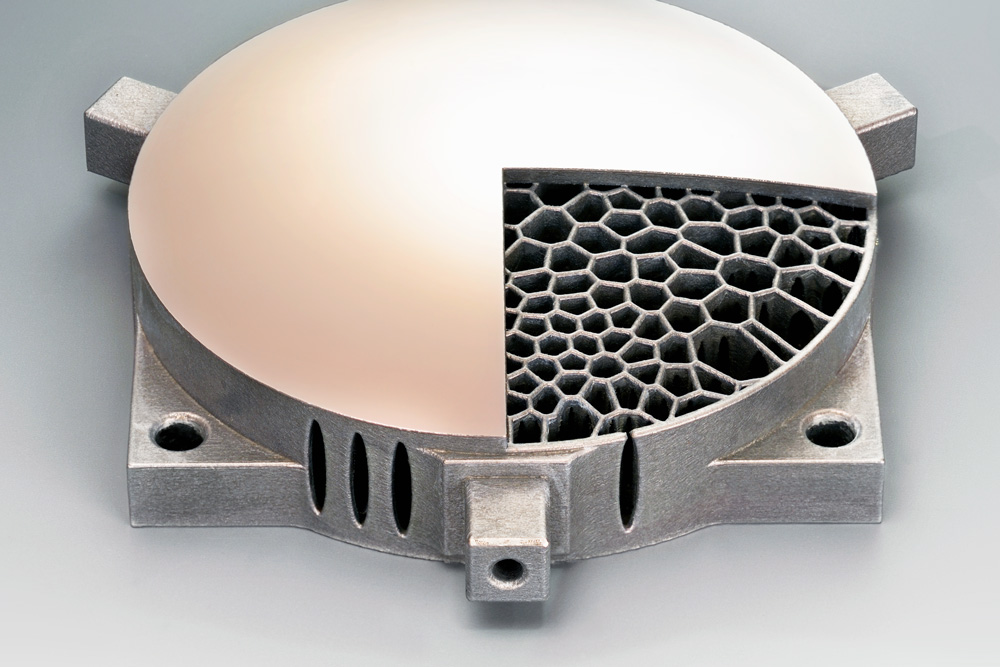

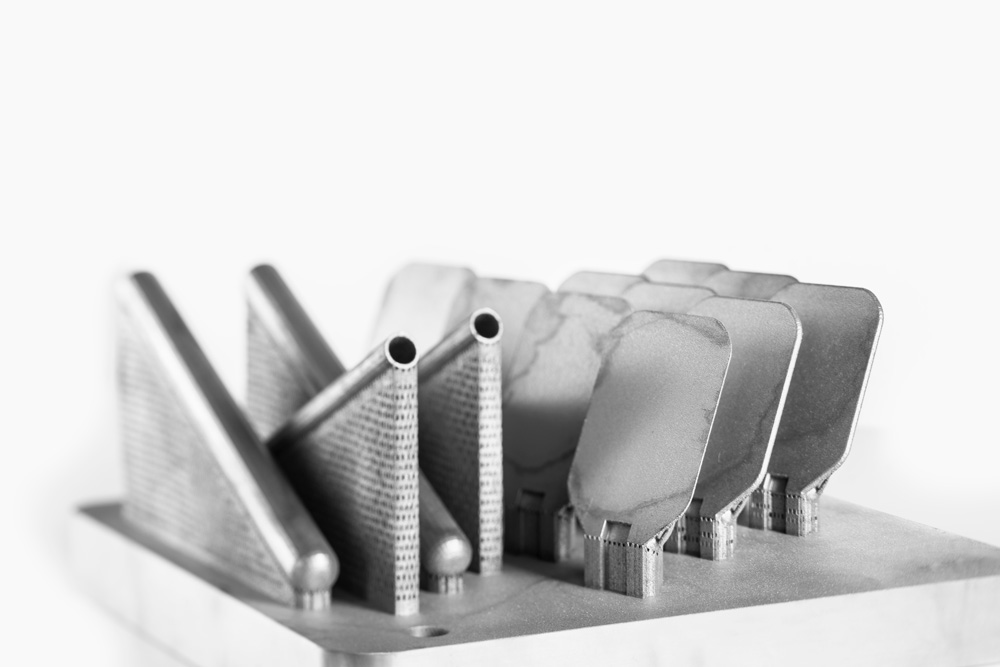

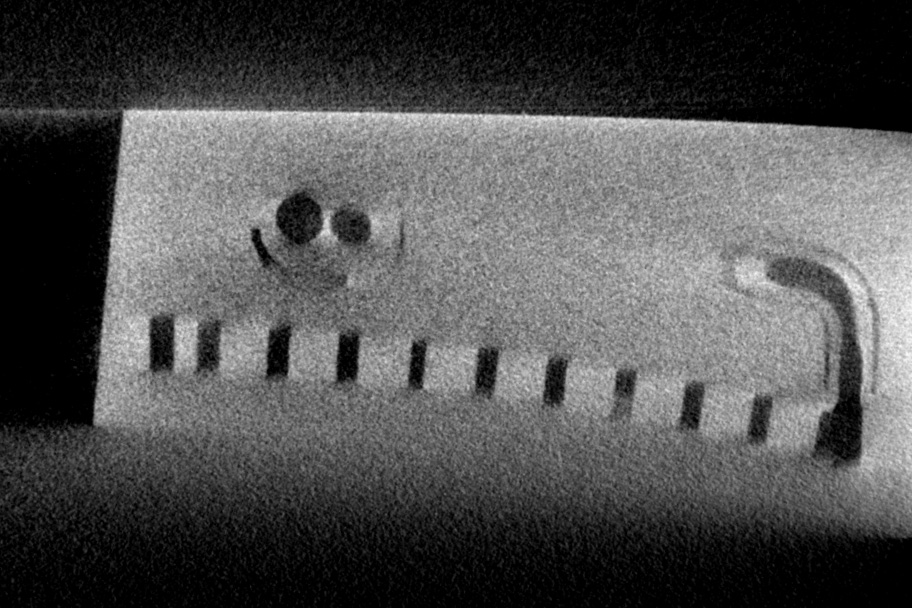

After extensive process studies, optimized parameters for the processing of the powder based raw material have been evaluated. The processing of aluminium-silicon material with a high silicon content of up to 40 % (AlSi40) is possible, realizing a very low porosity of 0.05 %. Studies of material samples show a Young’s modulus of 100 GPa and a tensile strength Rm of 260 MPa. The mechanical values are better than the conventionally manufactured semi-finished products. The coefficient of thermal expansion of AlSi40 is matched to the successively applied polishing layer, minimizing thermal induced bending effects. Computer tomographic measurements (CT) enable the geometric testing of internal volumes and complex structures of the manufactured parts.

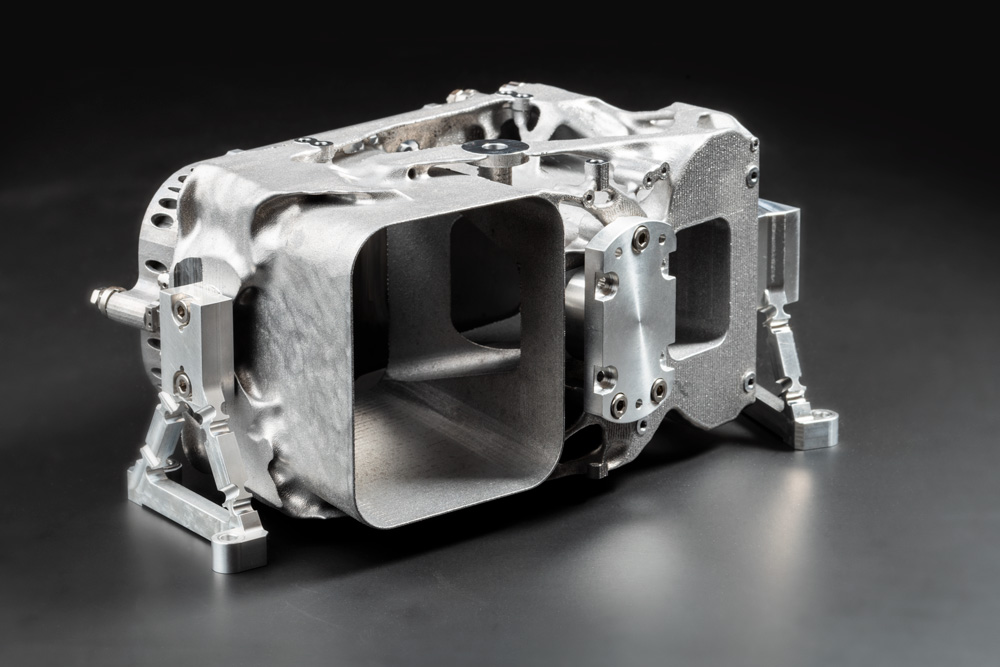

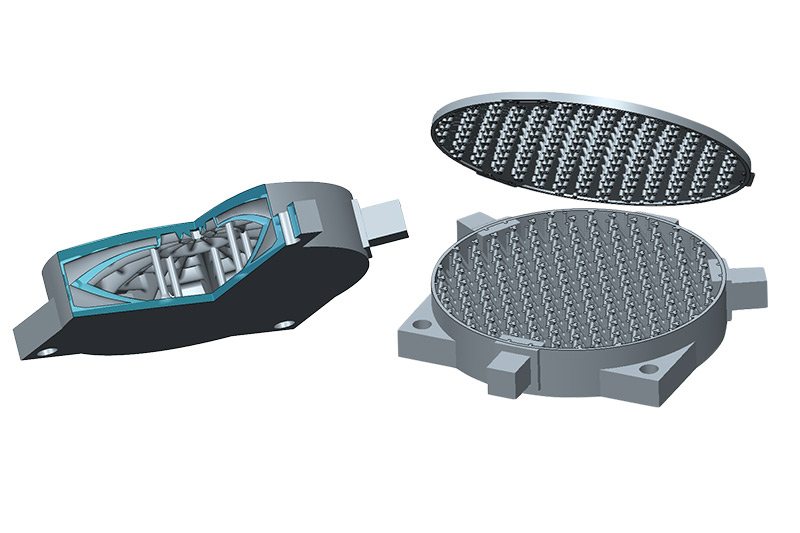

The direct integration of cooling channels into high power optics enables a uniform temperature distribution even for high thermal loads. The disadvantages of conventional methods such as additional bonds or uneven distances to the optical surface can be eliminated by AM.

Topologically optimized designs allow scan mirrors to achieve improved torsional frequencies (12 kHz), enabling higher scan speeds and thus more efficient laser material processing.

The reduction of mass while retaining the mechanical stiffness of mirrors is a major advantage for space applications. Mass savings of up to 70 % can be achieved.

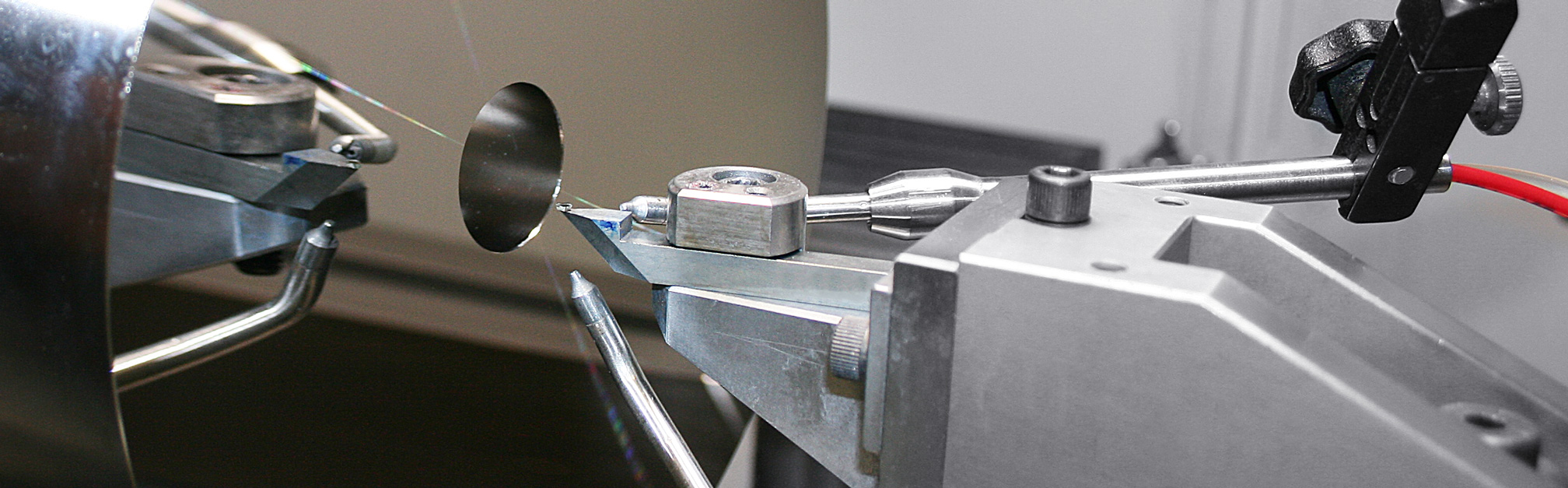

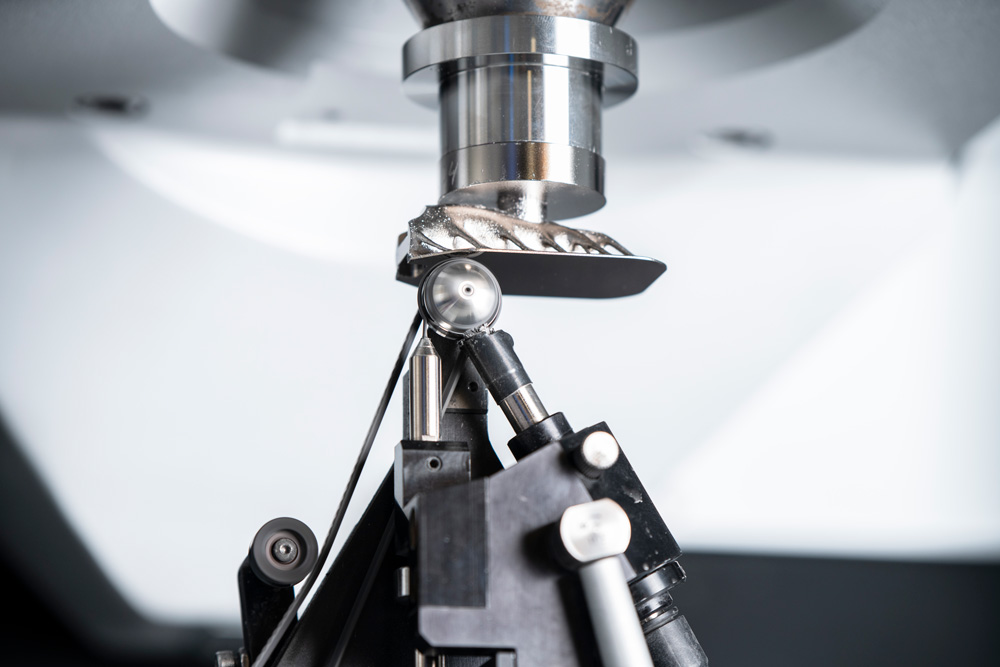

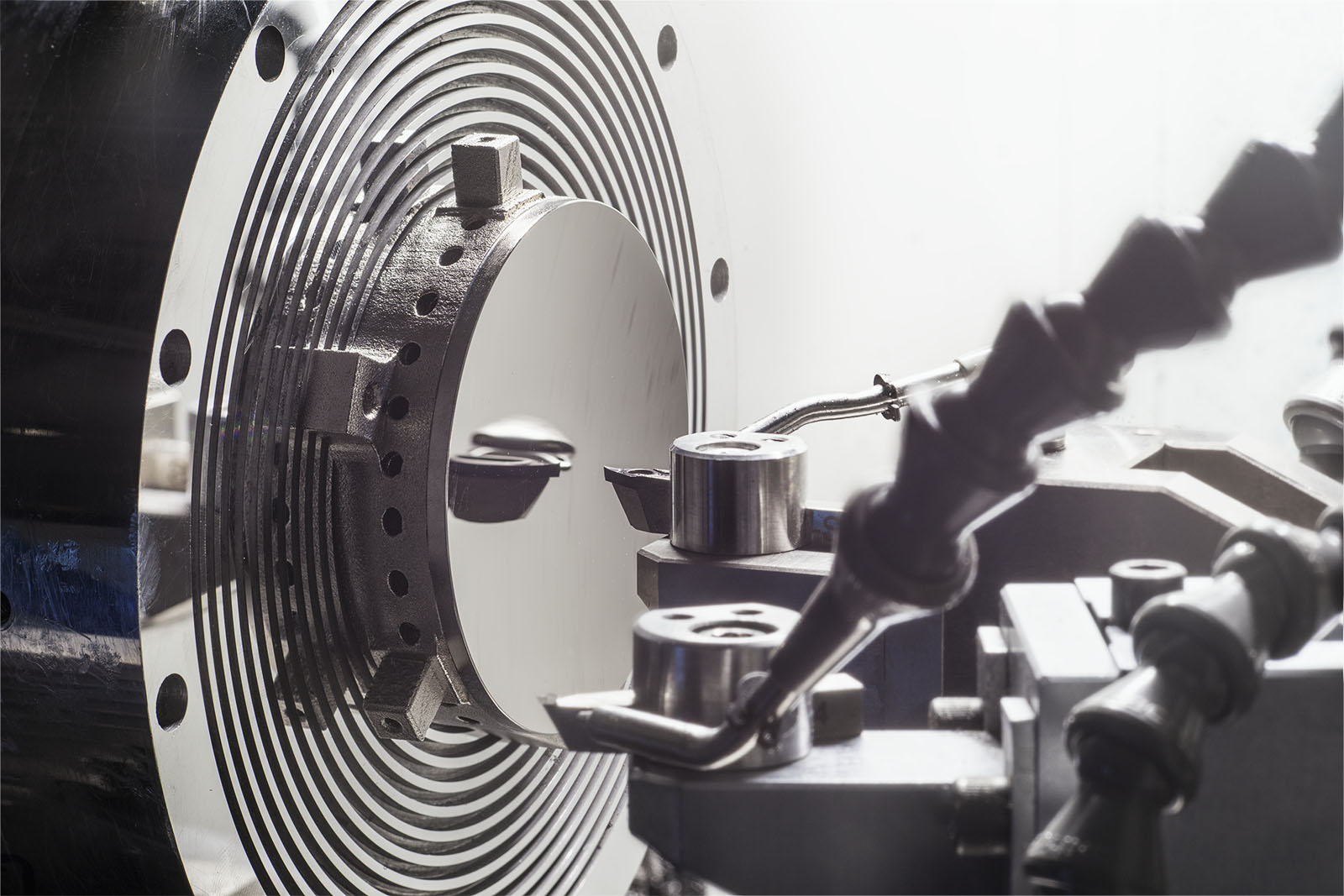

The additively made mirror bodies are processed using the established production chain for optical components including diamond turning, coating, and polishing. After the final processing using the established technology chain (diamond processing – magnetorheological polishing – chemical-mechanical polishing), shape deviations of less than 150 nm peak-to-valley and surface roughnesses of < 1 nm RMS have been achieved.

Acknowledgement

The research project “AM-OPTICS” is funded by the German Federal Ministry of Education and Research (BMBF) within the Program “Innovations for Tomorrow’s Production, Services, and Work” (02P15B204) and managed by the Project Management Agency Karlsruhe (PTKA).