Objective

Machining small structures in glass, ceramics, silicon, composite materials and refractory metals with CNC-Technology.

Technology

- ULTRASONIC assisted grinding with specially coated tools

- Integration of ULTRASONIC spindle in a standard CNC-milling machine.

Characteristics

- Spindle rotational speed 0 - 42 000 rpm

- Maximum workpiece dimension: 350 mm x 240 mm x 340 mm

- Minimum tool diameter 0,4 mm

- Working tolerance: < 10 µm

- Control system Siemens 840D

Competence

- Fabrication of holes, special milling contures and free form surfaces in brittle materials.

- Quartzglass, BK7, Borofloatglass

- Ceran, Zerodur

- Aluminium oxide

- Sintered caramics

- Zircon oxide

- Silicon

Applications

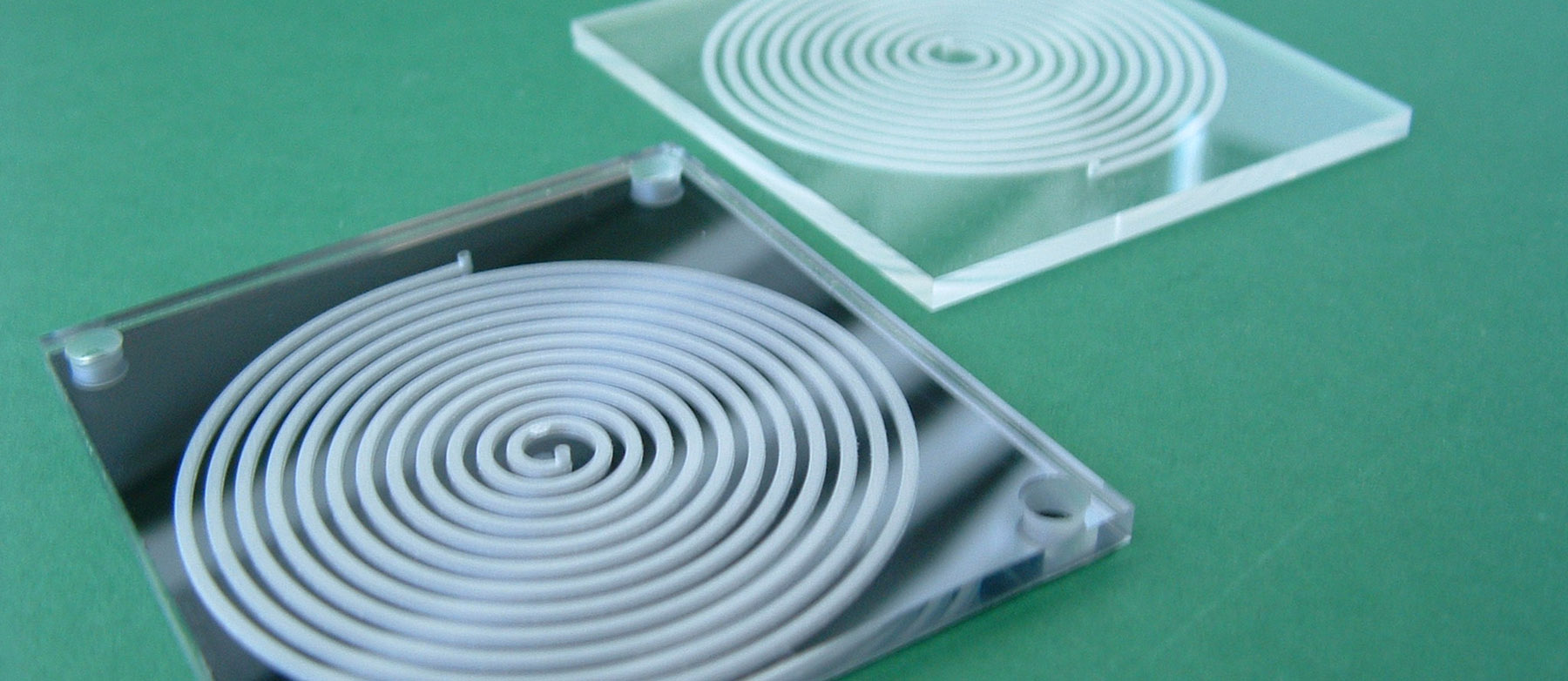

- Cooling structures in silicon wafers

- Dosing coils in glass

- Support components of glass materials

- Mechanical bedstops for optical components

- Aperture holes in optical components

- Holes in composite ceramics

- Free form surface in glass