analytica: Fraunhofer IOF presents high-resolution spectral measurements with miniaturized optics

Flexible microspectrometer for mobile applications

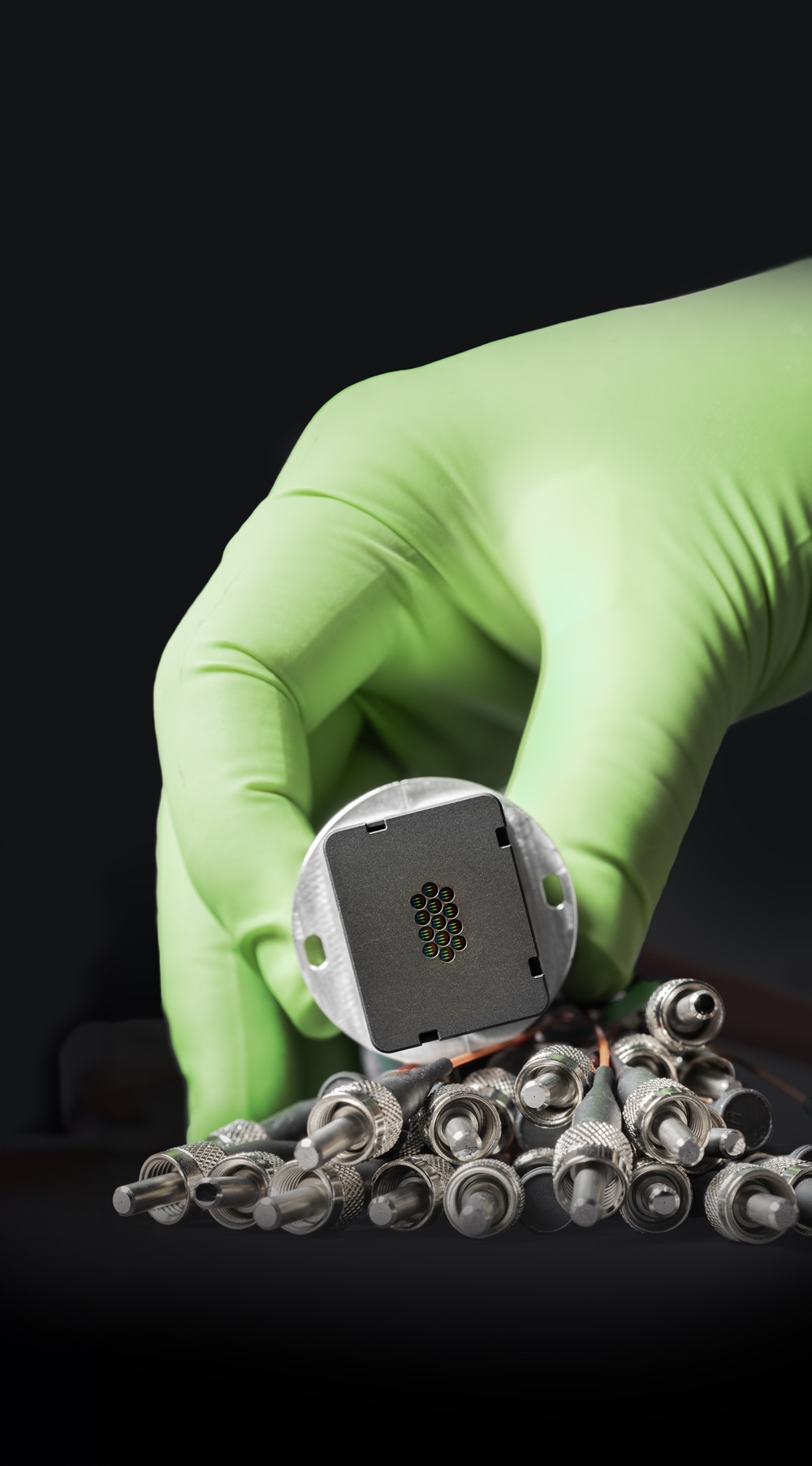

Researchers at the Fraunhofer Institute for Applied Optics and Precision Engineering IOF have developed a very compact spectrometer module. It maps spectra from 39 optical fibers onto one camera sensor in a small space. This is made possible by a special micro-optical system. The technology, which has potential for applications in quality assurance and analytics, will be presented at analytica trade fair in Munich from April 9 to 12.

If you want to spectrally analyze the light from many distant measuring points, you can either use several separate micro spectrometers or complex laboratory equipment. Neither is an option when it comes to flexible or even mobile applications. A team from Fraunhofer IOF has now developed a solution in which light is flexibly guided to a single, very compact optical system using 39 optical fibers. This maps the spectral information onto the image sensor of a camera.

Micro-optics for spectrometer array

At this year's analytica trade fair, Fraunhofer IOF is presenting a demo system with the new spectrometer optics at booth A3.407. However, not much of it can be seen - because it is so small. The researchers from Jena have developed a special micro-optical system for processing the light transmitted via optical fibers. It consists of many spectrometers arranged next to each other, forming what is called as a spectrometer array.

Each channel contains a prism-grating-prism arrangement between achromatic micro lenses. The micro lenses are separated by spacers to prevent crosstalk between the channels. This array arrangement allows to mount all spectrometer channels at once and results in an optical system length of less than two centimeters.

Despite the limited dimensions, the system maps the spectrum from around 400 to 800 nanometers. A resolution of 0.6 nanometers per pixel is achieved with the corresponding CMOS sensor.

Compact optics for quality assurance and analytics

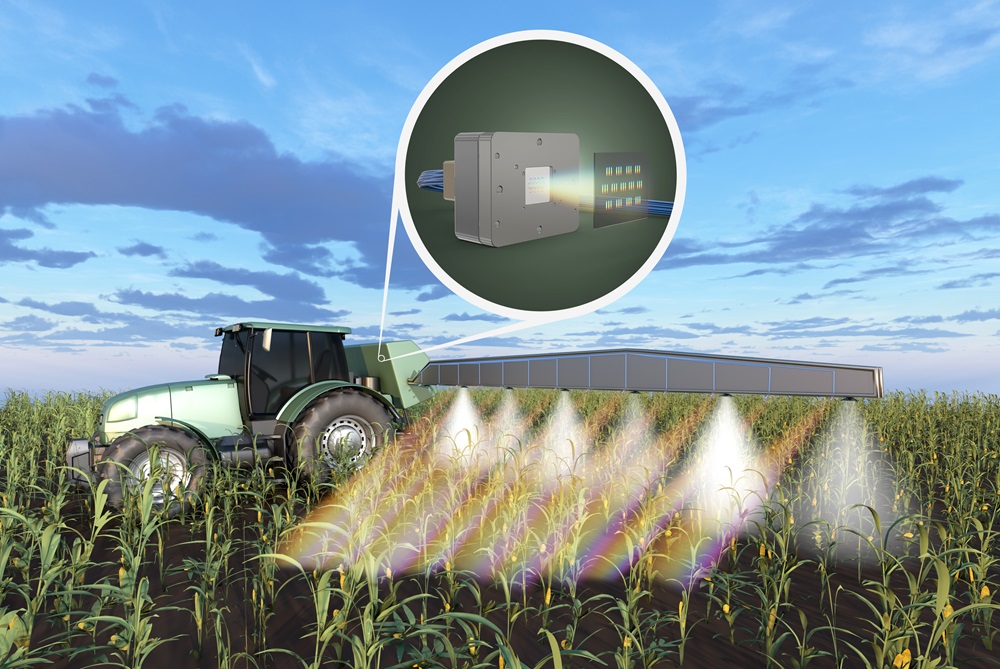

The technology has been developed for applications where spectral measurements are required at many positions or over large areas. This applies, for example, to the optical analysis of coatings or printings, to parallel measurements in bioanalytics as well as to digital agriculture, e.g., to check the health status of plants. Thanks to the integrated design, the setup is robust and can be integrated into existing systems easily.

The team from Fraunhofer IOF has developed the technology to application maturity over three years with the support of the Thüringer Aufbaubank. The task now is to optimize it for specific applications with the appropriate partners. For example, the spectral resolution could be adjusted, or the spectral measuring range can be extended to 1,600 nanometers – even different parameters of the channels are conceivable.

Presentation at analytica 2024

The Fraunhofer IOF team will be presenting the compact micro spectrometer at this year's analytica trade fair in Munich from April 9 to 12 at the Fraunhofer booth A3.407.