Reflection-reducing layer system and method of making the same

Invention of: Pfeiffer, Kristin; Schulz, Ulrike; Szeghalmi, Adriana

Status: published September 19, 2019

German file reference: DE 10 2018 105 859 A1

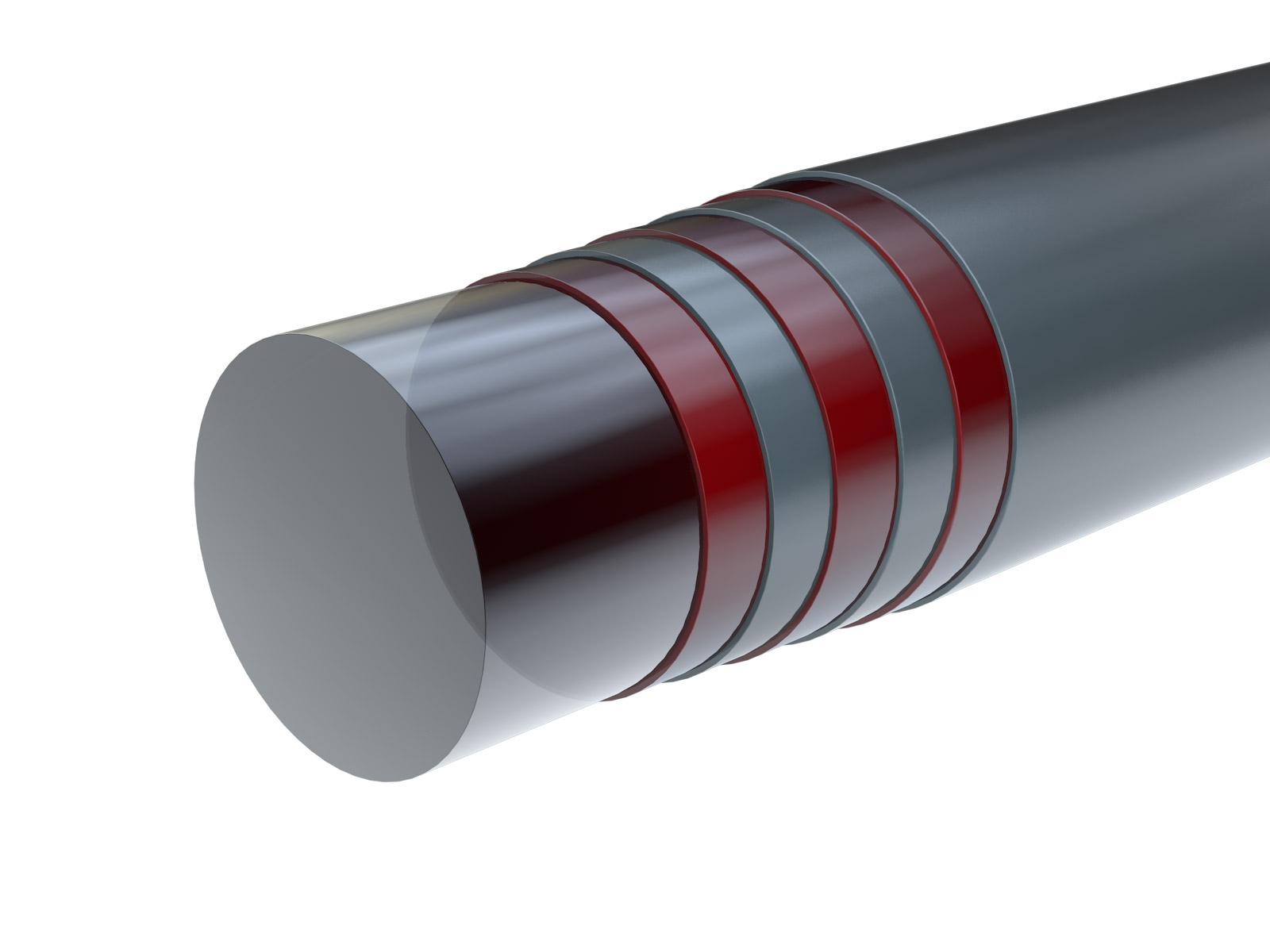

Abstract: A reflection-reducing layer system (20) is described which comprises an arrangement of alternating first layers (1) with a refractive index n1 and second layers (2) with a refractive index n2 > n1 as well as a cover layer (3) with a refractive index n3 < n1, wherein the first layers (1) comprise Al2O3, a proportion of the first layers (1) to the total thickness of the reflection-reducing layer system (20) is at least 40 %, a proportion of the second layers (2) to the total thickness of the reflection-reducing layer system (20) is less than 25 %, and the second layers (2) are each less than 35 nm thick. Furthermore, a method for producing the reflection-reducing layer system (20) by atomic layer deposition is described.

Process for the preparation of a reflection-reducing layer system

Invention of: Schulz, Ulrike; Szeghalmi, Adriana; Ghazaryan, Lilit (IAP); Kley, Ernst-Bernhard (IAP)

Status: granted July 18, 2019

German file reference: DE 10 2016 100 907 B4

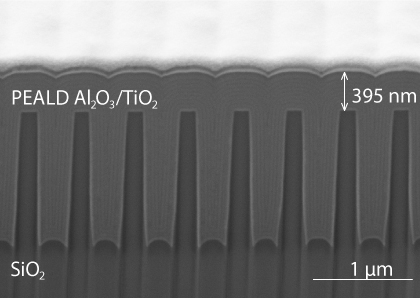

Abstract: A method for producing a reflection-reducing layer system (4), comprising the steps:

- Depositing a layer sequence (20) comprising a plurality of layers (1, 2) having different refractive indices on a substrate (10), wherein the layers are SiO2 layers (1) and Al2O3 layers (2) prepared by atomic layer deposition,

- Applying at least one mixed layer (30) to the layer sequence (20), the mixed layer (30) comprising silicon oxide as a first constituent and aluminum oxide as a second constituent, to the layer sequence (20), the mixed layer (30) being produced by atomic layer deposition, and

- Performing a wet chemical etching process, wherein the second ingredient is at least partially dissolved out of the mixed layer (30), wherein a porous layer (3) having a plurality of pores (13) is produced from the mixed layer (30).

Method of making a porous refractive index gradient layer

Invention of: Kley, Ernst-Bernhard; Szeghalmi, Adriana; Schulz, Ulrike; Ghazaryan, Lilit

Status: granted July 4, 2019

German file reference: DE 10 2016 100 914 B4

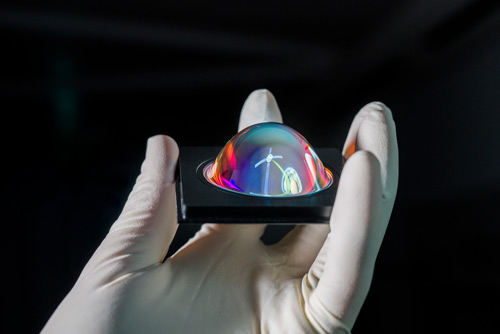

Abstract: A method of making a porous refractive index gradient layer (20) comprising the steps of:

- Depositing a layer stack (30) containing a plurality of mixed layers (1, 2, 3) onto a substrate (10), wherein the mixed layers (1, 2, 3) comprise silicon oxide as a first component and another material as a second component, and wherein a volume fraction of the second component of the mixed layers (1, 2, 3) in the layer stack (30) varies, and

- Carrying out an etching process in which the second constituent is at least partially dissolved out of the mixed layers (1, 2, 3), wherein porous layers (11, 12, 13) are produced from the mixed layers (1, 2, 3), which layers each have a plurality of pores (21, 22, 23), characterized in that the second constituent is aluminum oxide and the mixed layers (1, 2, 3) are produced by atomic layer deposition.

Process for the production of optically active elements

Invention of: Ghazaryan, Lilit (IAP); Szeghalmi, Adriana (IAP); Kley, Ernst-Bernhard

Status: granted February 22, 2016

German file reference: DE 10 2015 203 307B3

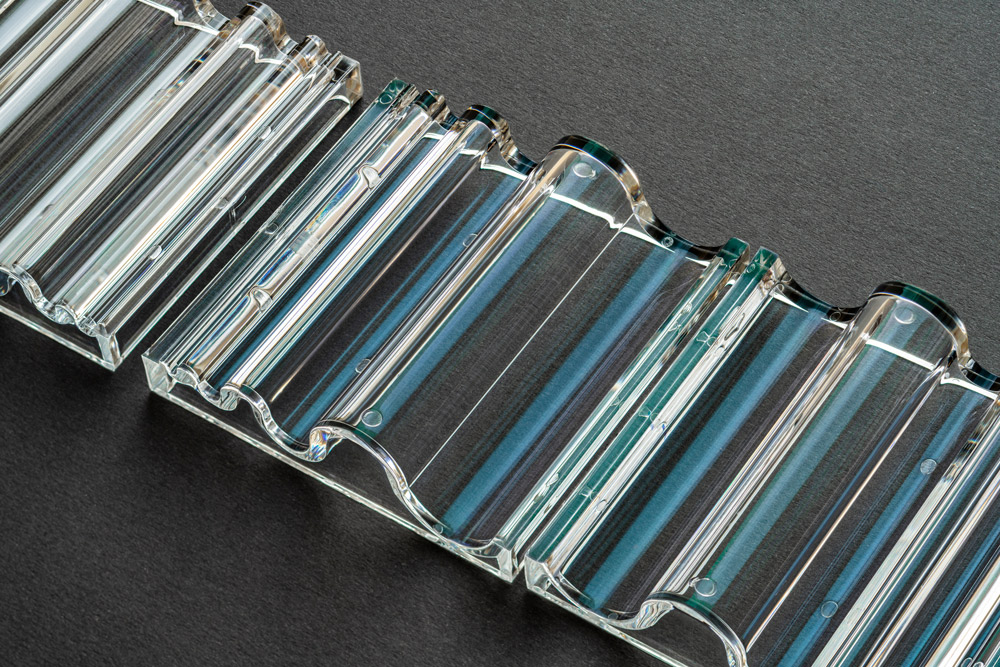

Abstract: The invention relates to a process for the production of optically active elements, in particular optical gratings, in which a structuring with depressions/interstices formed in the surface or a structuring is formed on the surface of a substrate and the structuring is covered with a layer. In a process step i), the formed depressions or interstices between elevations of the patterning are filled or sealed with a filler material, the filler material material differing from the material of the substrate and from the material from which the nanoporous covering layer is formed. In a subsequent process step ii), the filler material is removed to such an extent that no filler material is present on outwardly facing end faces of webs formed between and adjacent to the interstices. In a process step iii), the surface with the structuring and the filled interstices is coated with the covering layer, which is or is formed from a nanoporous material, and in a further process step iv), decomposition of the filler material is achieved by a treatment, and at least the decomposition products of the filler material formed are removed through open pores of the covering layer, so that cavities free of filler material are obtained in the region of the depressions, which are enclosed by substrate material and the material of the covering layer.