The wettability of functional surfaces is a challenge for various applications. Besides typical functions, such as self-cleaning (superhydrophobicity) and anti-fogging (superhydrophilicity), the use of strongly oleophilic or oleophobic surfaces for tribological systems, endoscopy, or under water sensors is of growing interest. Most of these applications require the investigation of their surface properties not only when surrounded by air, but also when immersed in water or any other liquid.

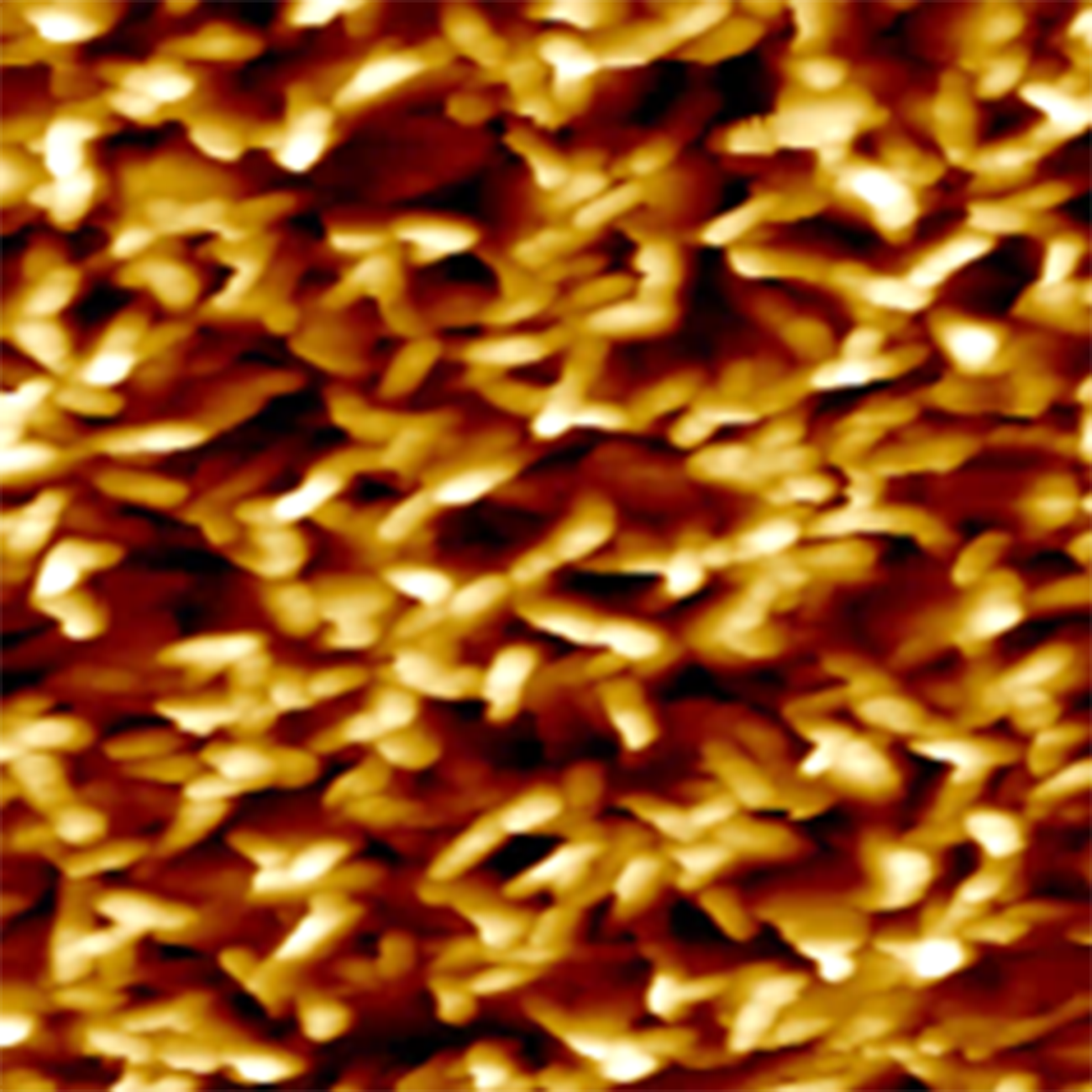

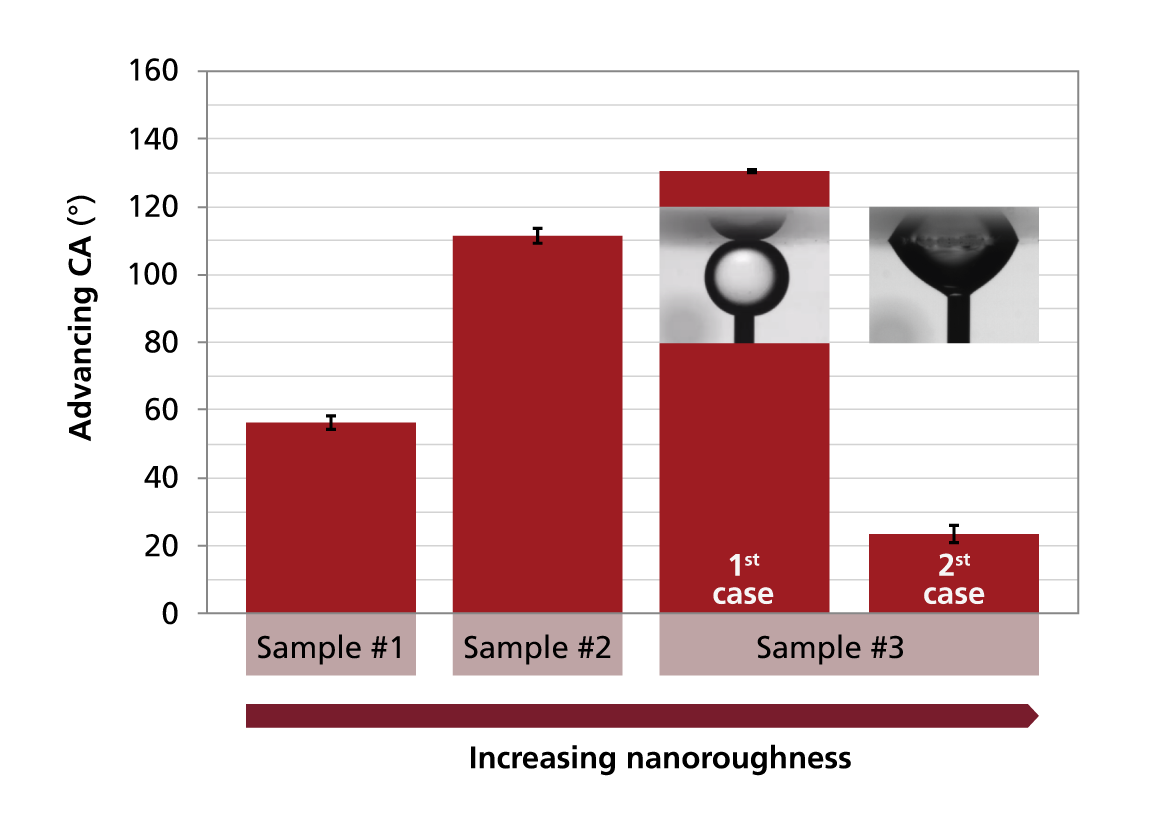

Fraunhofer IOF is working continuously towards the advancement of its wetting analysis methodology for a thorough understanding of the wetting properties of various systems adapted and optimized for specific applications. The latest development is an experimental setup for the investigation of wetting by oil while the solid surface is immersed in water. This setup (picture above) consists, among other components, of a bi-distilled water filled cuvette with high optical quality, and a curved needle to position the oil drops below the sample surface. Al2O3 sol-gel coatings with adjustable nanoroughness were manufactured and used to establish correlations between surface roughness and wetting with oil as the liquid phase. This investigation has shown that surfaces with a specific roughness (first picture on the left) and oleophilic behavior in air lead to a stable superoleophobicity when immersed in water (second picture on the left). Nevertheless, oleophobic surfaces in both air and water are required for underwater applications. Al2O3 coatings with a certain surface roughness and an additional top layer to minimize the surface energy exhibit oleophobic behavior in air. The surface roughness influences the wetting behavior when the Al2O3 coatings are immersed in water. The roughest sample (third picture on the left: #3) reveals an advancing oil contact angle higher than 100° (third picture on the left: 1st case) in both fluid phases (air and water). However, the oleophobic wetting situation under water is not yet stable: By increasing the pressure or small movement through the needle, transfers to the oleophilic wetting situation occur (third picture on the left: 2nd case). Further activities focus on the optimization of the quantitative wetting analysis method for underwater applications and the realization of stable oleophobic wetting systems. Research was performed within the framework of the BMBF joint project GLAMOR.

Authors: Luisa Coriand, Nadja Felde, Anna Gottwald, Angela Duparré