High Power Fiber Lasers at 1 μm and 2 μm

Fiber lasers are continuously increasing their market share in the field of high power lasers for material processing. They can be easily integrated into complex machines, efficiently cooled and provide good beam quality. Depending on the processed material, lasers with different spectral emission properties are advantageous. Fraunhofer IOF has developed high power fiber laser systems around 1 μm and 2 μm wavelength.

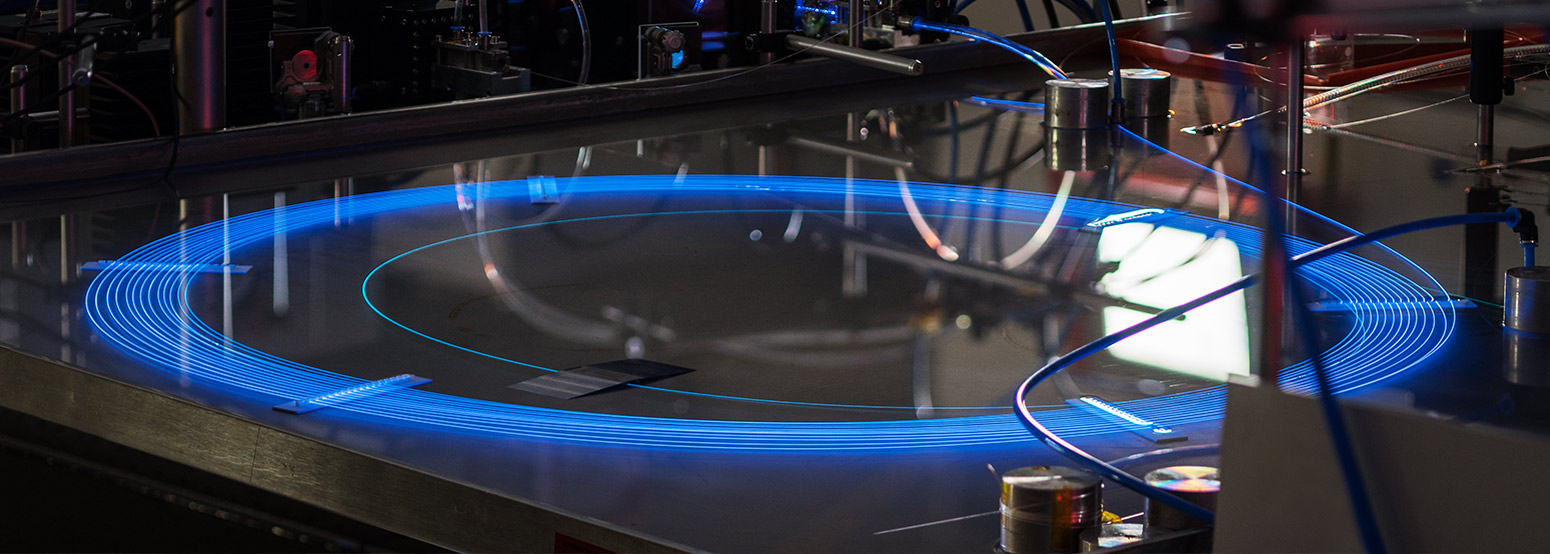

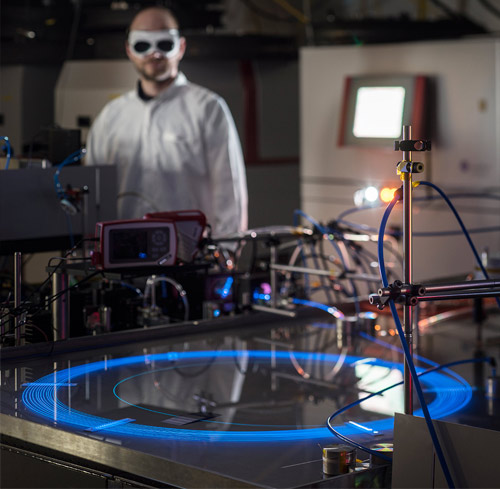

For the past few years, Fraunhofer IOF has been developing ytterbium-doped fibers. Significant progress has been made concerning fiber design and preform fabrication, enabling the drawing of step index fibers with ultra-low numerical aperture. This allowed the fiber core size to be increased while still maintaining single transverse mode operation, suppressing nonlinear effects and making higher laser powers possible. Simultaneously, the average heat load in the fiber was reduced by tailoring the doping concentration to avoid thermal destruction and the onset of (power limiting) modal instabilities.

By using an in-house fiber with a 23 μm core diameter and a numerical aperture of less than 0.04, Fraunhofer IOF was able to present an output power of 3.5 kW from a narrow-linewidth (180 pm) fiber system at 1067 nm central wavelength. Due to low ytterbium doping concentration, the heat load could be reduced and modal instabilities were avoided, maintaining near diffraction-limited beam quality. By increasing the spectral linewidth to 7 nm, power-limiting nonlinear effects could be further suppressed, increasing the achieved output power to a pump-limited level of 4.3 kW. This is the highest output power presented so far for such

a system.

The “eye-safe” spectral region around two microns is particularly interesting for medical applications, but also for the processing of plastics. Fraunhofer IOF has developed a diode-pumped monolithic fiber laser at 1970 nm wavelength based on thulium-doped fibers. The high quantum defect (generating additional heat) and high purity requirements for glasses in all components are specific challenges in such a system. By applying excellent cooling and optimizing splice technology, an all-fiber oscillator with 567 W output power and good beam quality could be implemented. It was stable in operation and only power-limited by available pump power.

Authors: Till Walbaum, Franz Beier, Thomas Schreiber