Motivation

End-face preparation is a key element of preparing fibers for components, amplifiers or entire laser systems.

Procedure

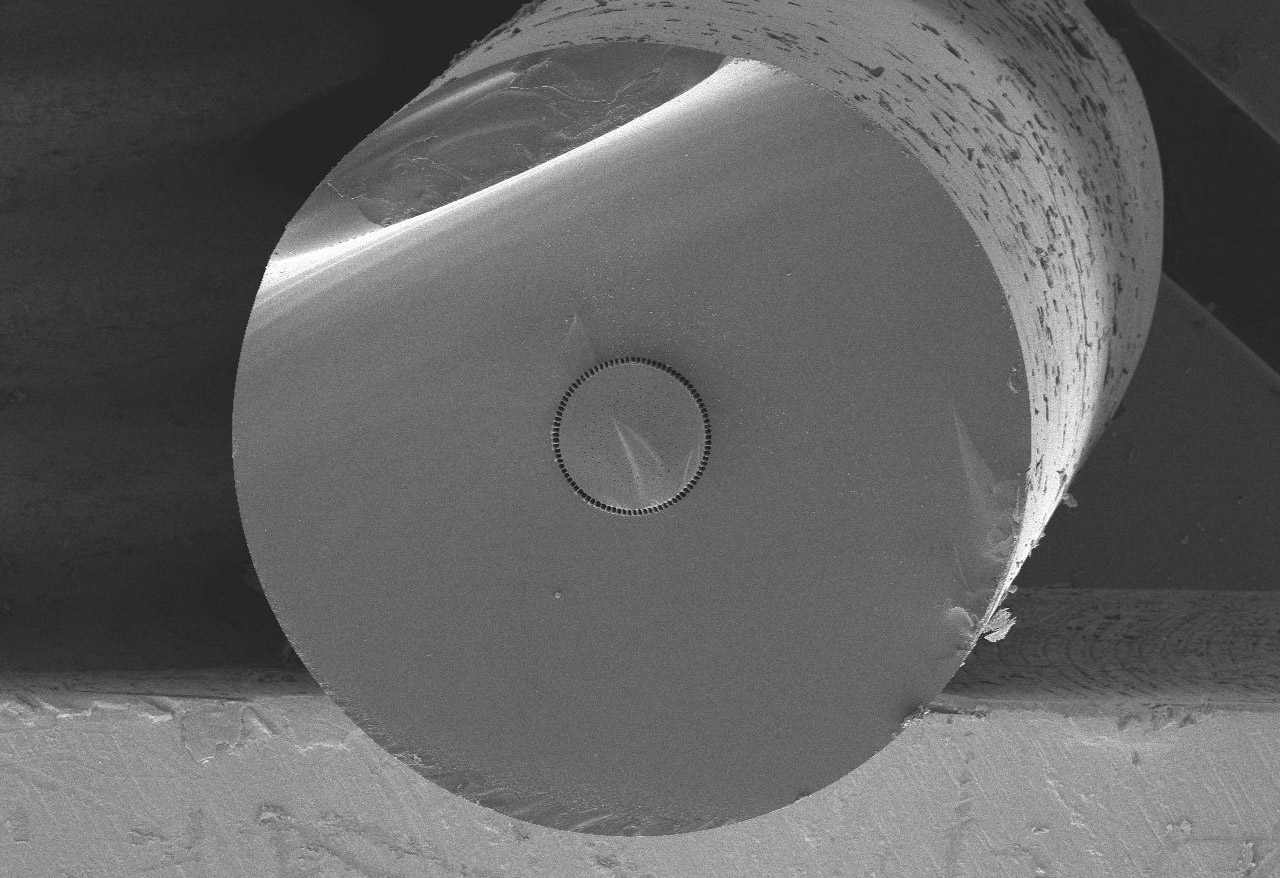

In addition to polishing, the controlled break of the fiber (cleaving) is the best method of preparation.

The cleaving process encompasses the following requirements:

- Optimum cleave angle

- Avoidance of surface unevenness

- Avoidance of cracks

- Avoidance of large glass splinters

The Fraunhofer IOF can cleave fibers with diameters of 125 µm to 1 mm.

Furthermore, in addition to standard fibers, special fibers such as photonic crystal fibers can be prepared. This is carried out with the aid of preparatory processes such as the complete or partial collapse of air holes in the glass cladding. These preparatory processes also include polishing with adapted fiber holders, as required at different angles.

Measurement

In addition to microscopic and scanning electron images, quality testing following cleaving is possible with white light interferometry and 3D height profile measurement.