Motivation

The tapering (extending) of light waveguides plays a key role in manufacturing high-performance components, e.g. for mode field adaptation in fiber lasers.

Procedure

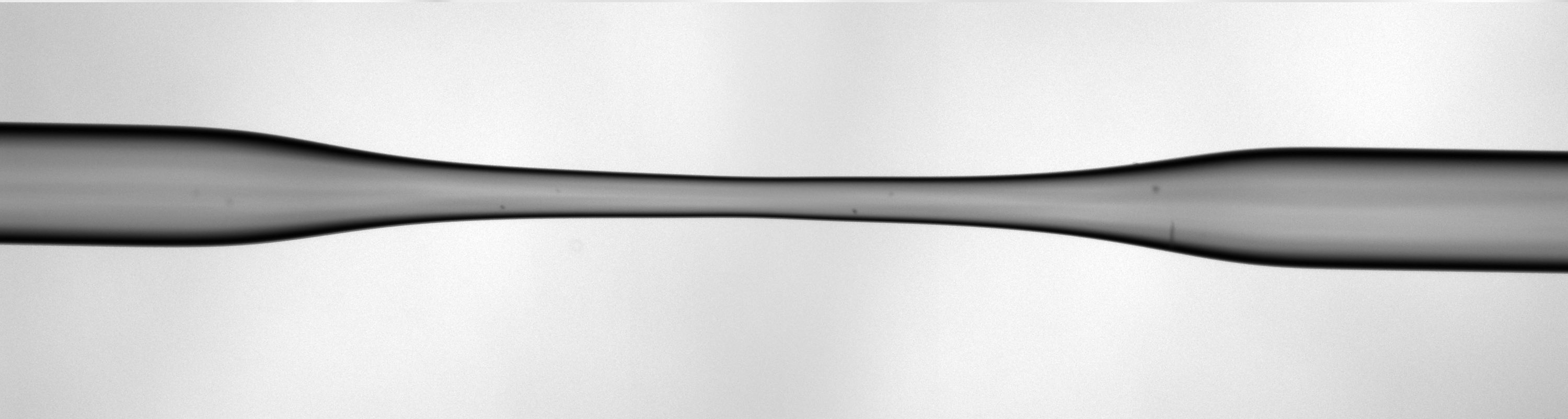

The tapering process can be realized with a CO2 laser as the heat source. A system of this kind was developed and is in use at Fraunhofer IOF. Tapering proportionally reduces the cross-section of the light waveguide, both in the core and the cladding. Following cleaving, a fiber with a reduced core diameter can be spliced to a fiber with the same core diameter.

The tapering process requires the even, radial heating of the light waveguide, until the glass viscosity has been reduced to below a glass-specific value which allows deformation. Two computer-controlled motorized axes with fiber holders then draw the light waveguide to the required diameter over a specific length. With various dopings, which result in different transformation areas, the laser power can be adapted to the glass to be processed.

Application

Fibers with large fiber diameters as well as capillaries can be processed using the CO2 tapering equipment. It is possible to manufacture different fiber-fiber splices and fiber combiners.