Diffraction Gratings with Tailored Spectral Response

Hyperspectral imaging is a technique of combining imaging and spectroscopy to survey a scene or target, and extract detailed information. The scene’s spectral properties are obtained at hundreds to thousands of narrow wavelength bands within an entire spectral field of view, which typically spans over one octave or more. The collected and processed data serve the function of characterizing and identifying chemical compositions, materials, or liquids, which can then be referenced to a precise location in a scene.

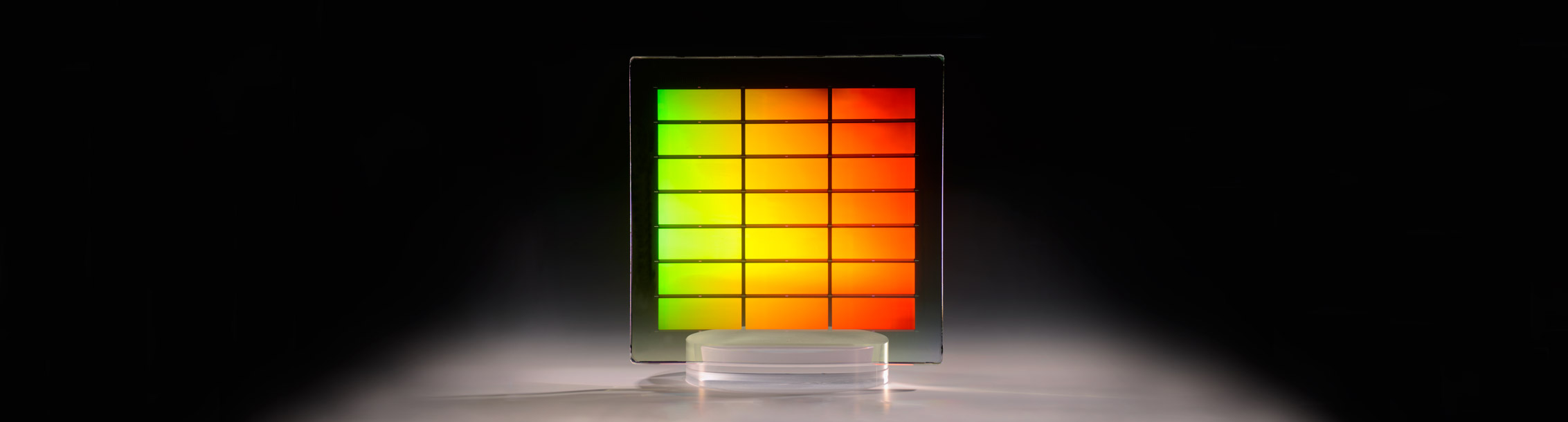

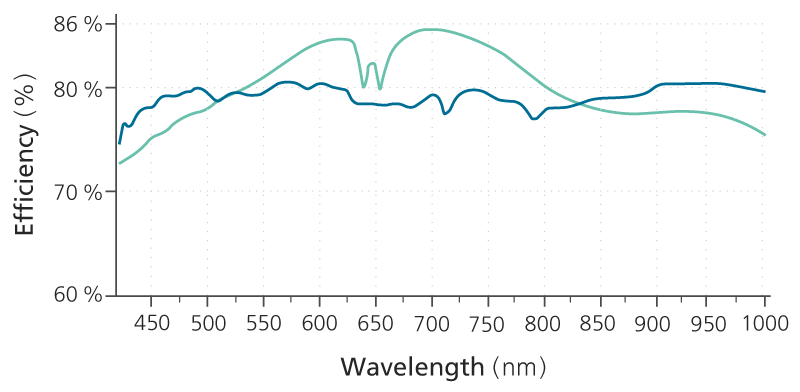

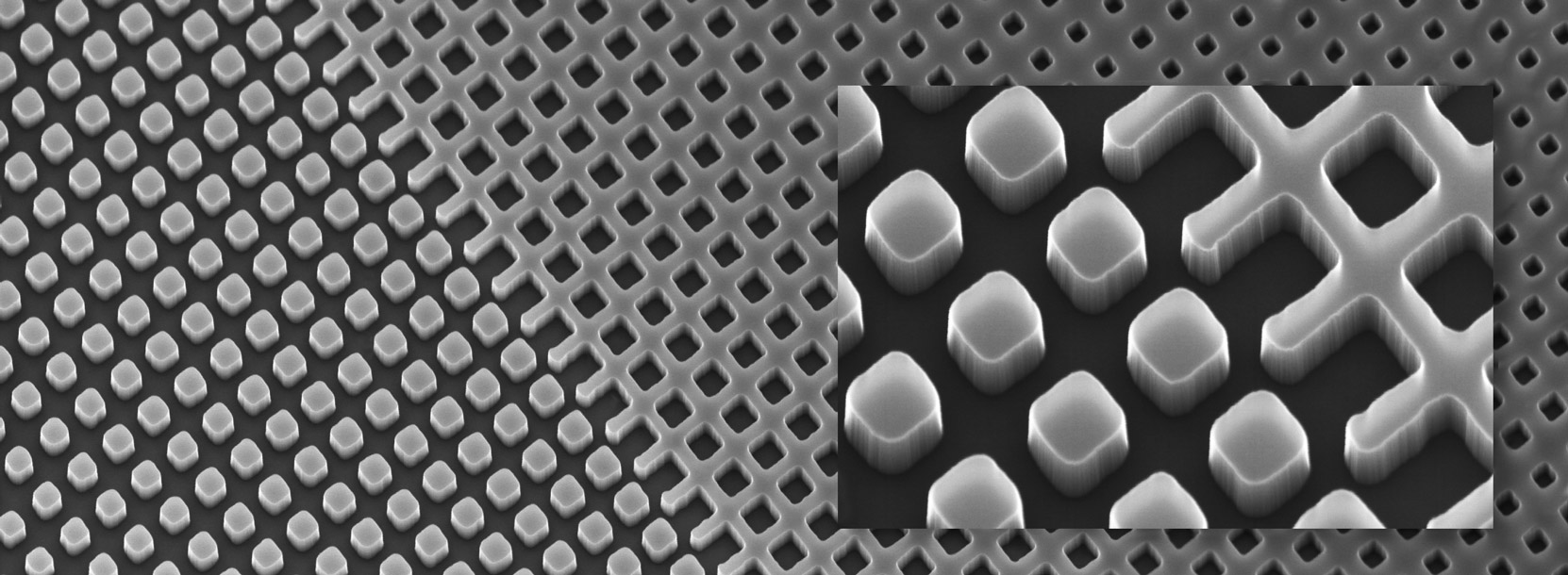

The correct balancing of the optical sensitivity throughout the entire spectral bandwidth is one of the major challenges of designing hyperspectral instruments and it comprises all parts of the system – from the detector and optical components and, of course, the dispersive element(s). Using gratings as dispersive elements is most often the method of choice as they allow compact and lightweight devices.