Technology

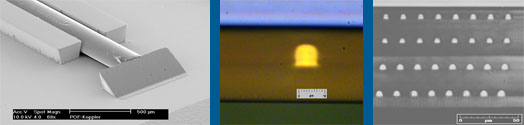

By coating (e.g. spinning on) and exposure by a mask with subsequent development process, waveguide components can be directly written into UV-curable polymers.

Preferred materials are anorganic-organic hybrid polymers, synthesized at Fraunhofer ISC in Würzburg.

- The production is simple and exclusively carried out with photolithography devices and process steps, typically on 4” wafer size

- Single-mode and multi-mode

- Refractive index variation with co-polymerization

- Very good planarizing properties

- Stacking of waveguide layers is possible

- Thermo-optical components

- Low losses in wavelengths from 1.3 µm and 1.55 µm

Examples

- Passive components such as 1 X N and N X M distributors in various configurations

- Waveguide arrays for basic research

- 3D waveguide fan-out element as optical HF summator

- Biosensors on the basis of surface plasmon excitation in multimode strip waveguides

- Integration of waveguide structures with microoptics

- Thermo-optical switch with low cross talk

Services

- Mask layout and production in accordance with design, adapted to technological requirements

- Production of components

- Development of processes and technology transfer

- Characterization and in-process measurements

- Material selection and characterization

- Investigations on stability of optical properties for special fields of application