The development of ‘‘smart‘‘ biomaterials and the functio-nalization of surfaces for medical applications have been key issues for many years not only in medical field, but also in various natural sciences such as biology, chemistry, physics, and materials science. An effective fabrication of biomaterials with specific functionalities and optimal biocompatibility demands a thorough understanding of their individual properties (e.g. topography, roughness, wettability, mechanical strength) and relationships. This results in increased requirements for appropriate characterization methods and analysis techniques. Fraunhofer IOF continuously refines its roughness and functional analysis methods to achieve a comprehensive enlightenment of the structural and functional properties of different surface and thin film coatings. This comprises an optimization of existing, or a development of novel, methods with respect to the specific application. The first approaches have been made to extend our measurement and analysis methods for effective prediction, defining, and controlling of roughness structures for optimal hydro/oleo-phobic/-philic wetting properties to biomedical surfaces.

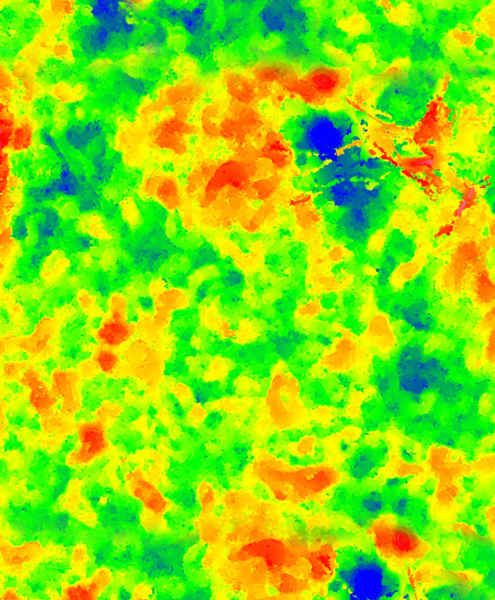

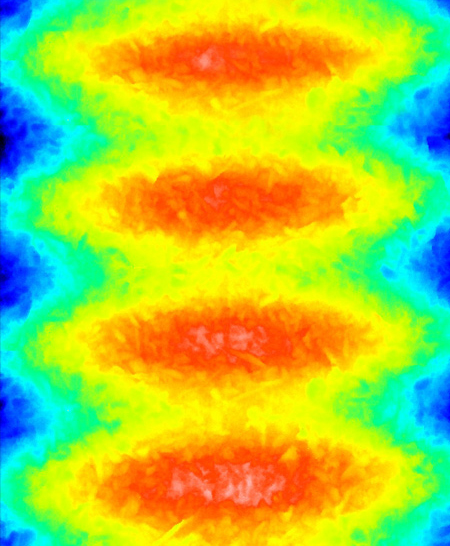

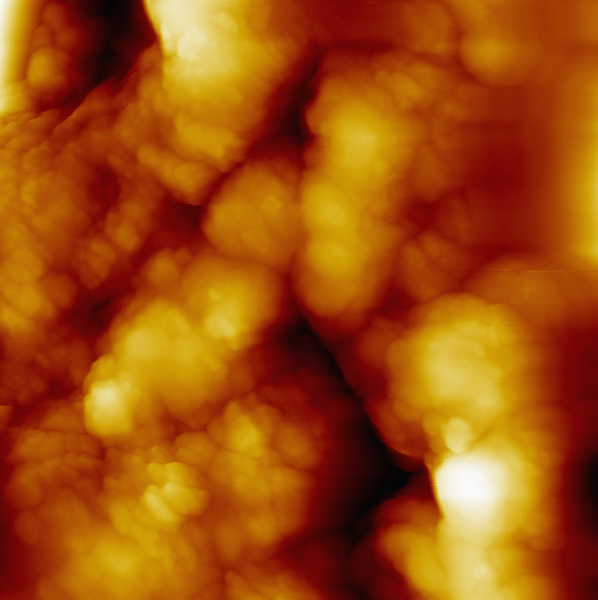

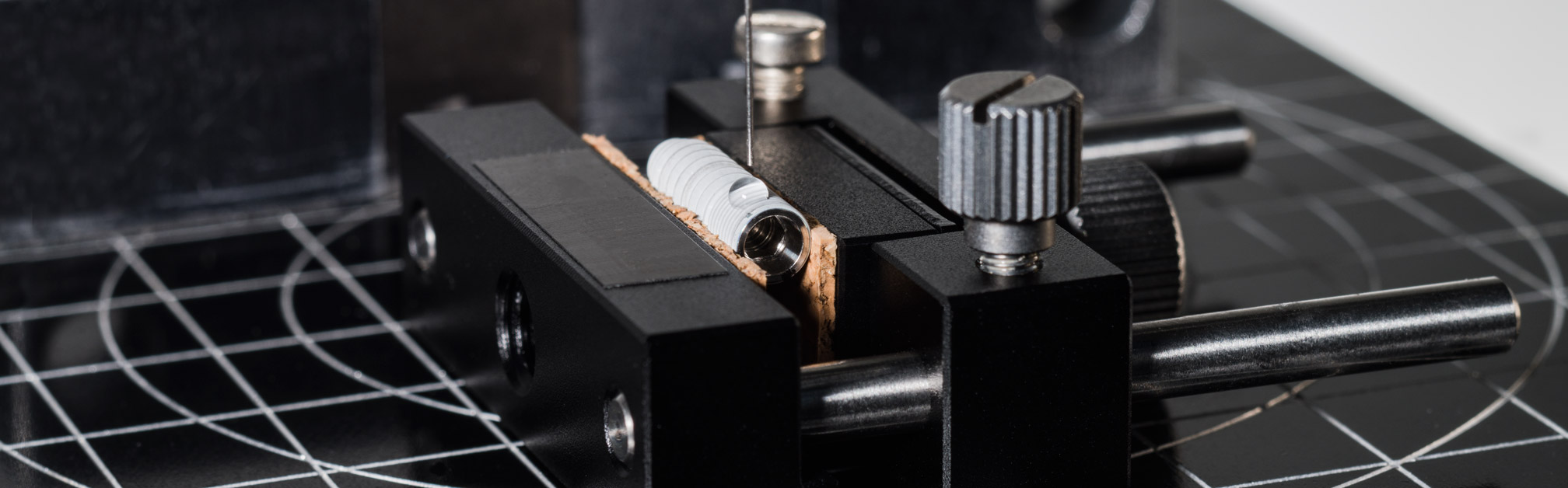

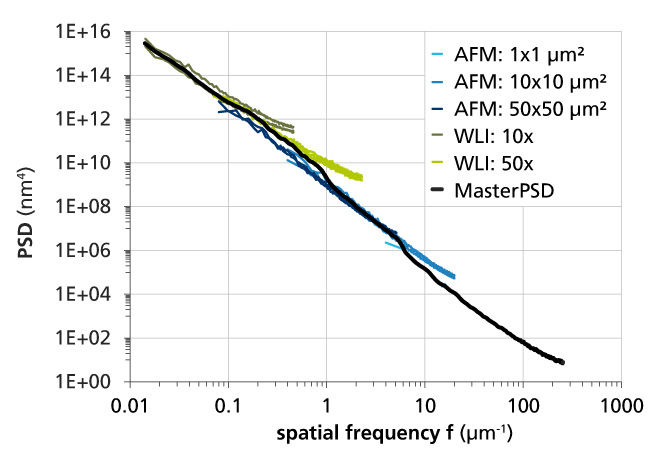

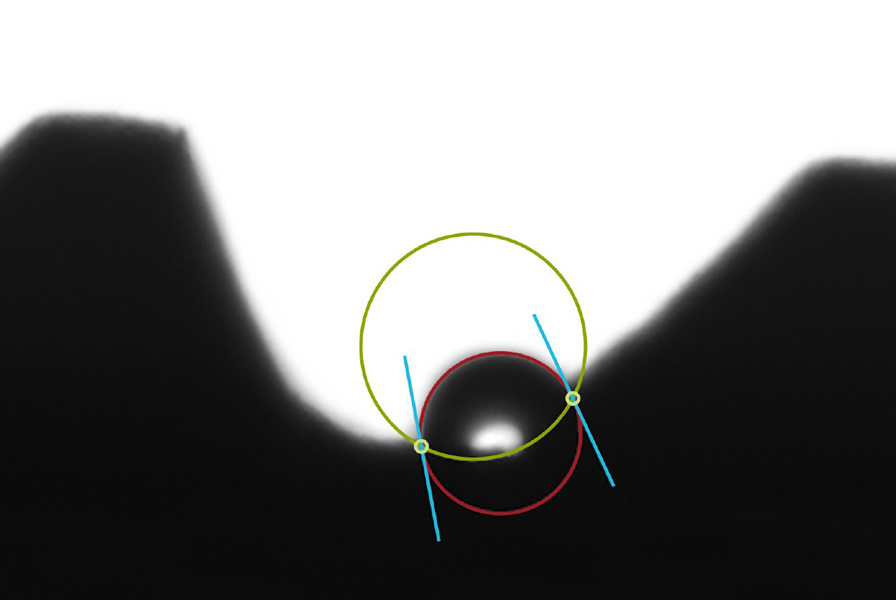

The Power Spectral Density (PSD) function yields data on the vertical as well as lateral distributions of the roughness components and, hence, constitutes the basis for an advanced structural analysis. The combination of PSDs obtained fromdifferent scan areas and different measurement techniques enables a robust roughness analysis over a wide spatial frequency range of dental implants (Fig. 1), for instance. Figures 3A-C show the topography of Laser-Scanning-Microscope (LSM), White-Light-Interferometer (WLI), and Atomic-Force-Microscope (AFM) measurements. The calculated single PSD functions and combined MasterPSD are depicted in Figure 2A. The same applies to the wetting behavior: A pure qualitative description or utilization of only one contact angle is only sufficient for a first assessment; however, a suitable evaluation and comparison of the specific wetting properties requires characterization methods that are well defined and focus on the particular application. For this purpose, a huge number of techniques as well as methods are available at Fraunhofer IOF. For example, the nanoliter dosing system (DataPhysics) enables an investigation of the wetting behavior at the bottom (Fig. 2B) or at the edge of the dental implant thread instead of the entire implant surface.

Authors: Luisa Coriand, Nadja Felde, Torsten Knieps (medentis medical GmbH), Sven Schröder