Motivation

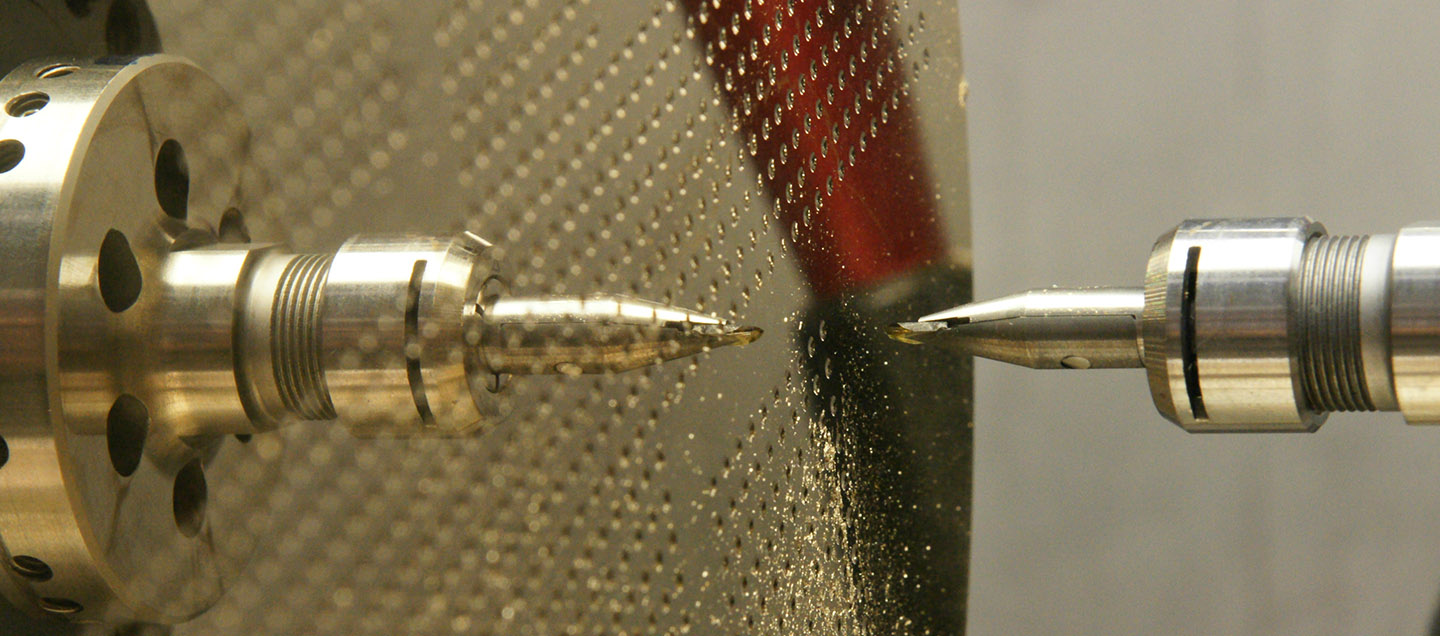

Ultra-precision cutting with diamond tools enables flexible manufacturing of various surface shapes in optical quality.

The Fraunhofer IOF develops and qualifies advanced manufacturing technologies for generating complex optical shapes. Even sophisticated requirements given by the optical design will be realized with modern

machine equipment.

After the systematic analysis, the adequate machining technique (diamond turning, flycutting, shaping, micromilling) will be selected and further developed to fit the particular application.

Optical Components, Mirrors

- Rotationally symmetric: plane surfaces, spherical and aspherical shapes

- Complex optical shapes such as parabolic, ellipsoidic, conic surfaces, off-axis aspheres

- Non-rotational-symmetrical surfaces, toric, cylindric

- Freeform surfaces

- Segmented surfaces

Microstructures

- Micro lens arrays

- Reflection gratings, transmission gratings

- Fresnel structures

- Grooves

Moulds

- Replication tools for plastics (hot embossing, injection moulding, UV reaction moulding)

- Tools for glass hot moulding