Motivation

Optical components are subject to a diverse range of requirements which can often only be achieved with hybrid integration. Connecting the various components while ensuring they are stable in the long term is a major challenge. Techniques such as wringing or bonding are either not stable enough or create problems arising from the necessary annealing steps when joining different materials. Intermediate layers as required when bonding or soldering can also exhibit issues relating to long-term stability or resistance to heat.

Competence

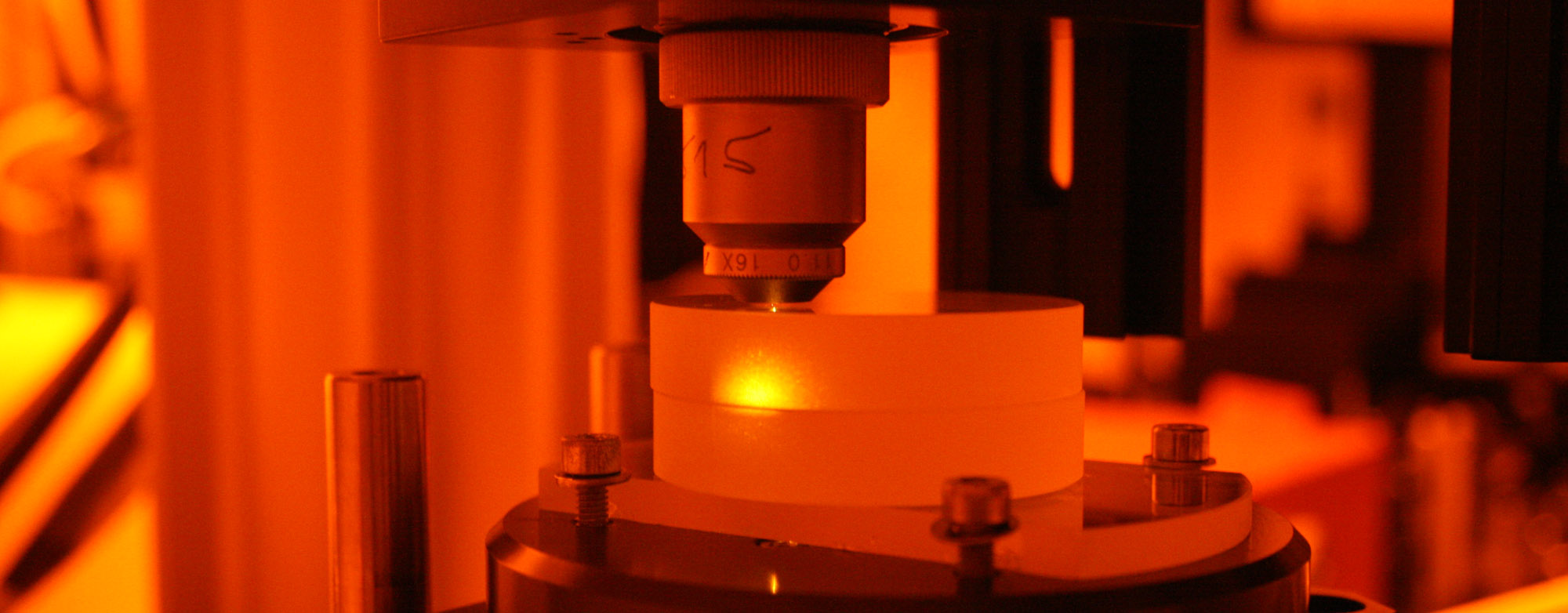

The Fraunhofer IOF has developed an ultrashort pulse laser technology which is used for local welding.

Benefits of the technology:

- Defined local energy input

- Minimization of thermal stresses in the material

- Fracture strengths up to 75 % of the volume material

- Joining of different glasses is possible

Application:

- Micro-optics

- Sensors

- Photovoltaics