Motivation

Diamond properties (thermal conductivity and extreme hardness) complicate the production and preparation of diamond tools. Not all cutting geometries for diamond tools can be realized using abrasive methods. In addition, the time and material input required for processing diamond tools is considerable.

Competence

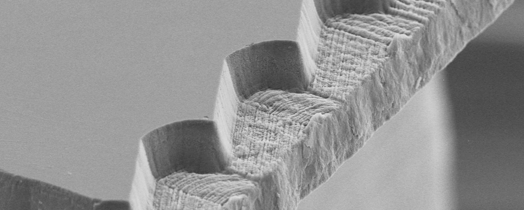

The Fraunhofer IOF has developed a technology for delineation and processing of diamond tools using ultrashort laser pulses.

Benefits of the technology:

- Processing independent of the crystal direction of diamonds

- Rapid processing

- Virtually all forms realizable

- Local and time-limited energy input results in smallest possible tool damage

Specifications:

- Structure size down to the micrometer range

- Surface roughnesses to 30 nm (rms)

- Lips with minimal edge sharpness (radius) of up to 400 nm

Use of the technology

- Production of highly-precise surface structures and diamond milling tools

- Use in connection with a surface finish as an initial precision cut for producing diamond turning tools