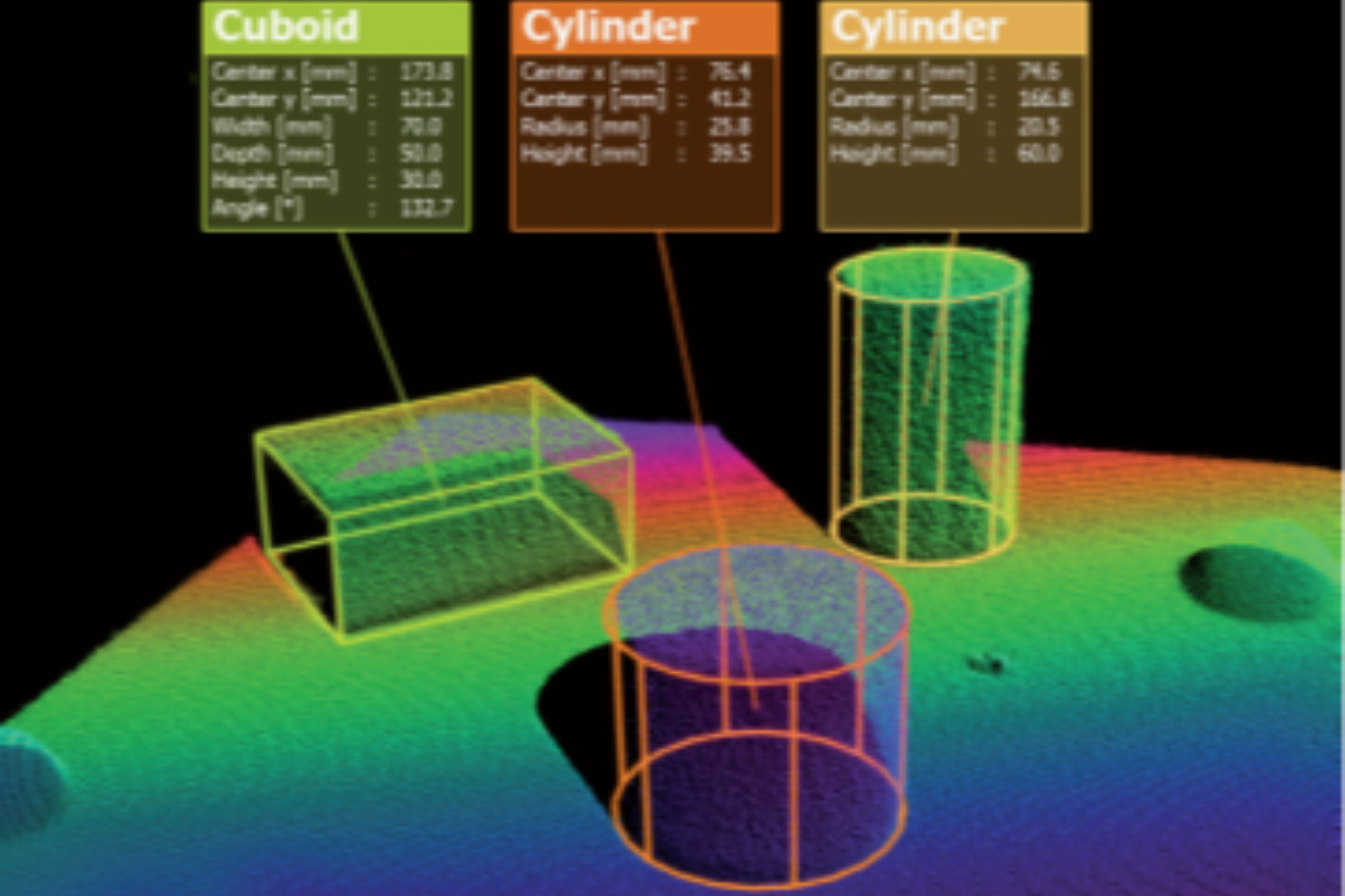

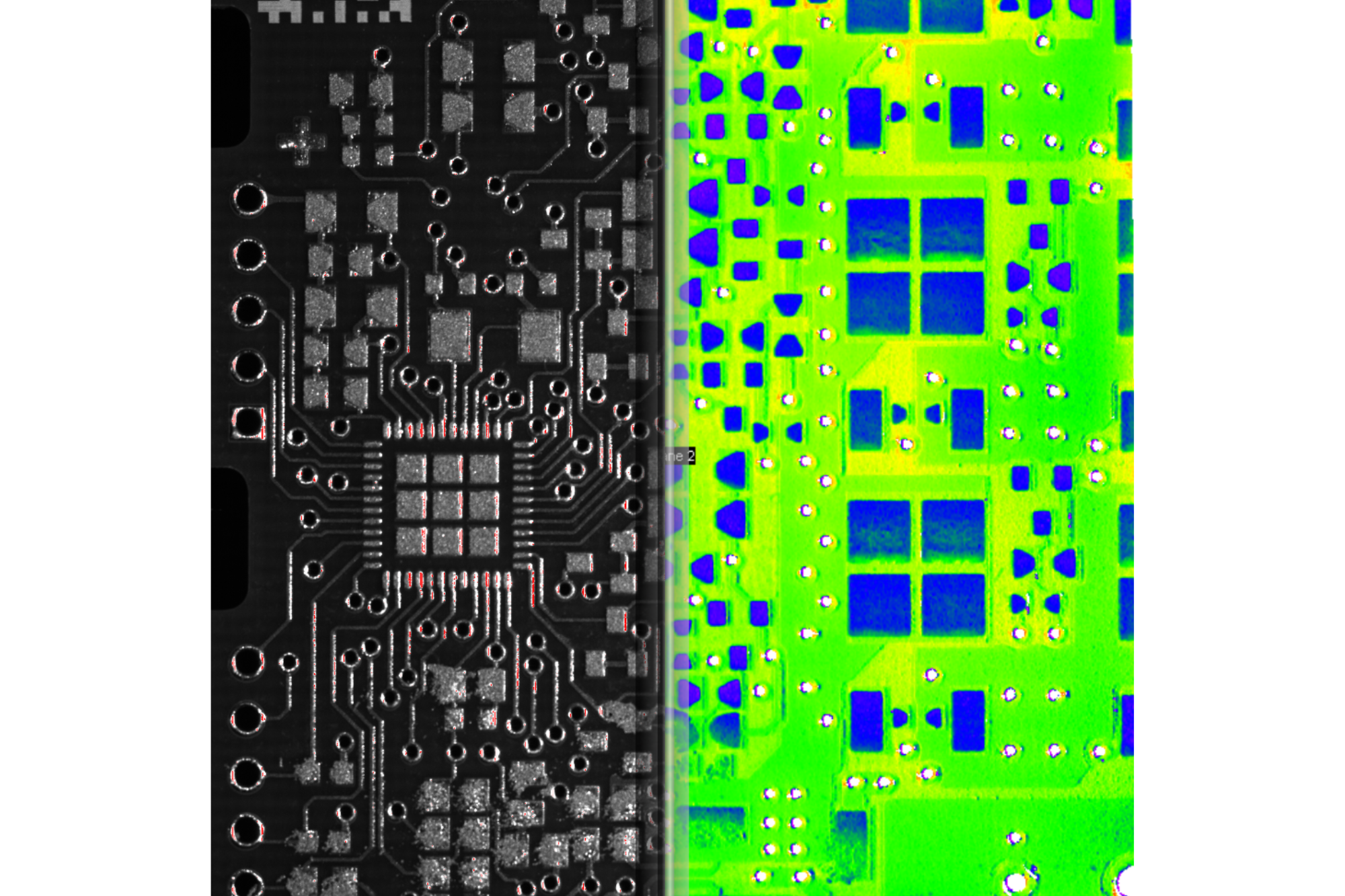

Highly integrated real-time capable in-line 2D and 3D measurement systems

Challenging and industry-compliant continuous measurements of complex objects with impressively short cycle times on conveyor belts or in robot handling in automated inspection systems.

We specialize in measurement solutions for special applications that go beyond conventional standard solutions. Our dedicated team of scientists and technicians test, develop and implement innovative in-line 2D and 3D measurement systems according to the individual requirements of our customers and research partners. With our experience, we bring your tailor-made solutions from the idea to the application and support you in the further optimization of your production processes even after successful launching.