Functionality of CT technology

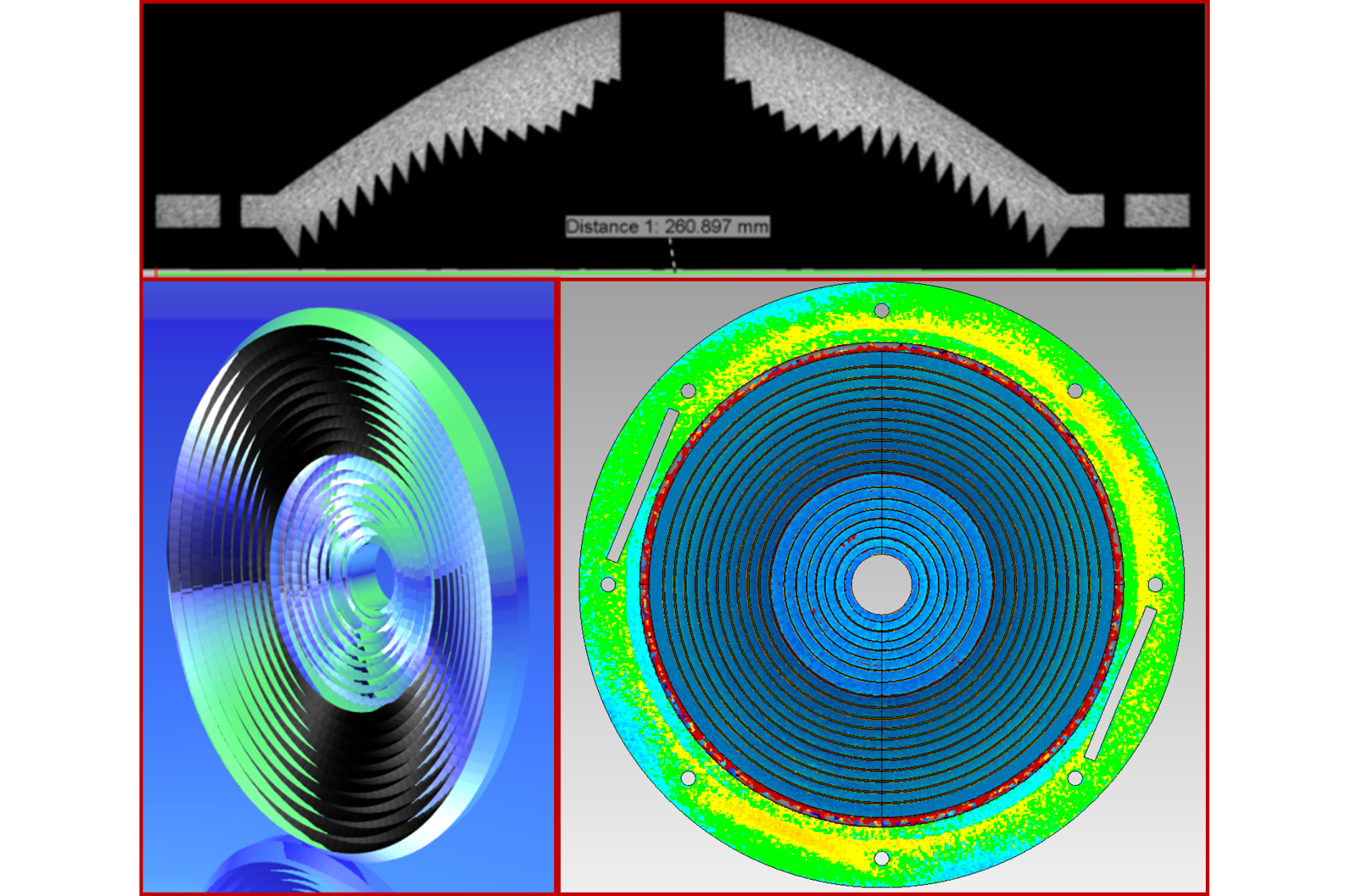

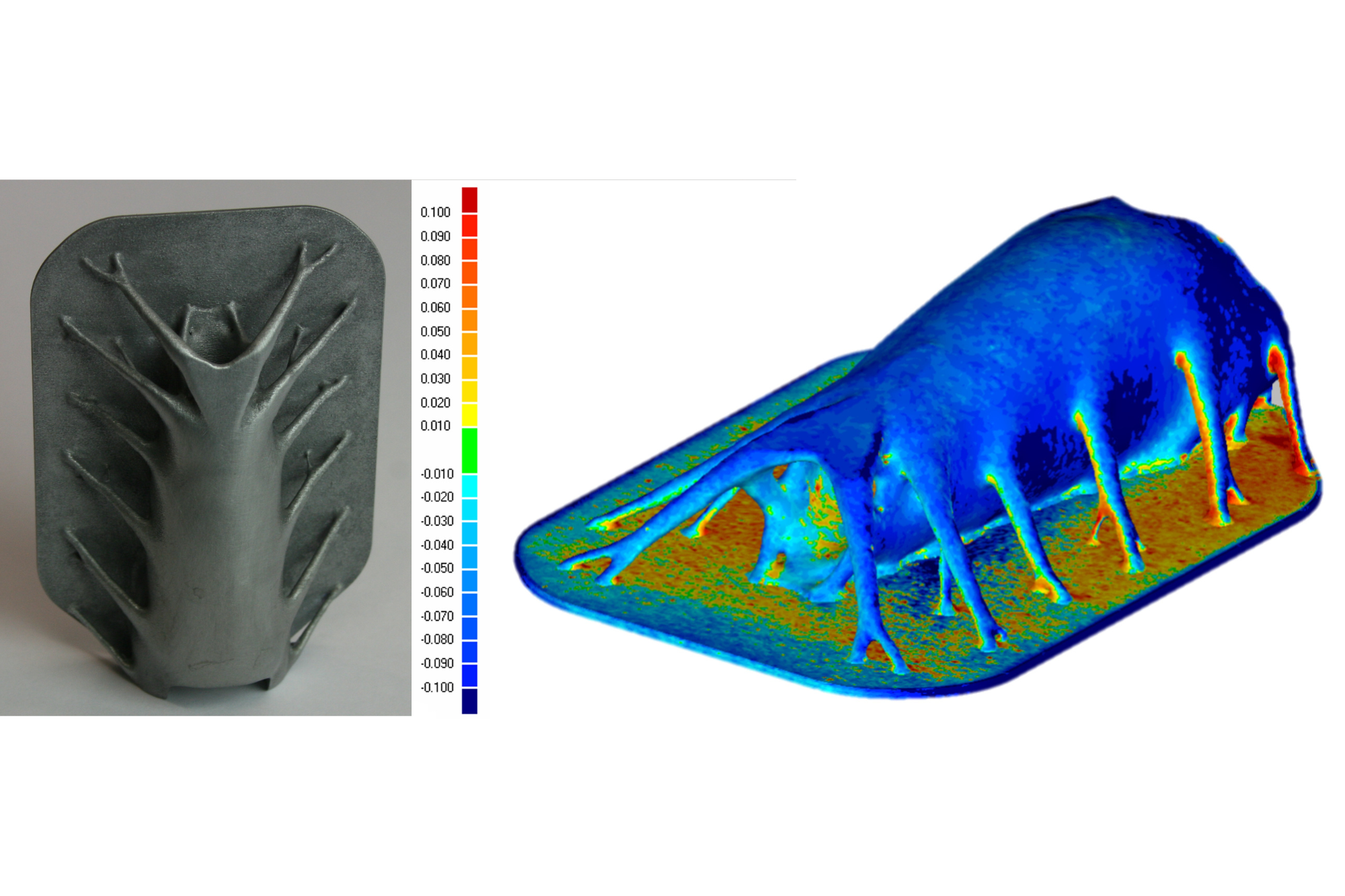

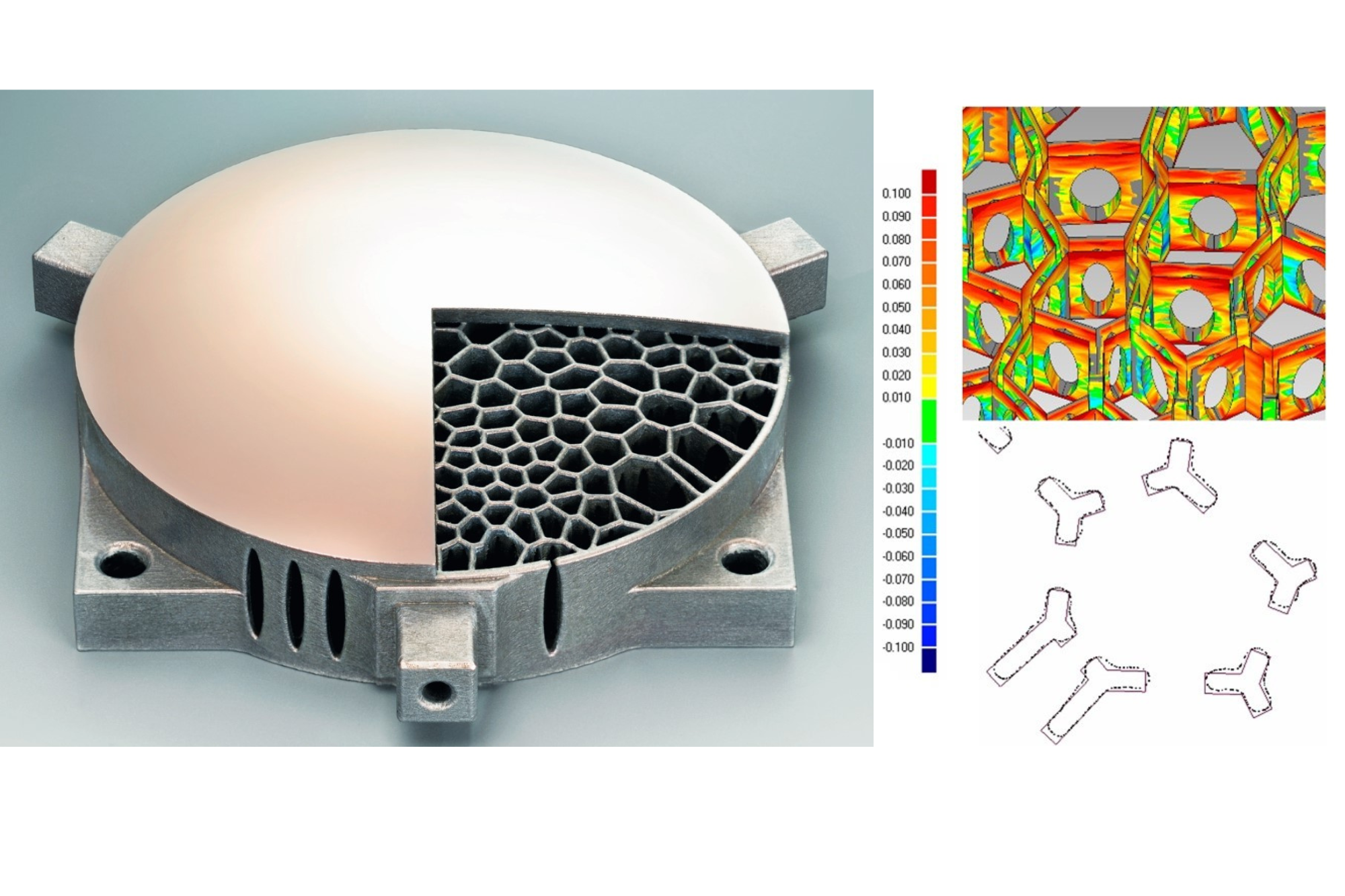

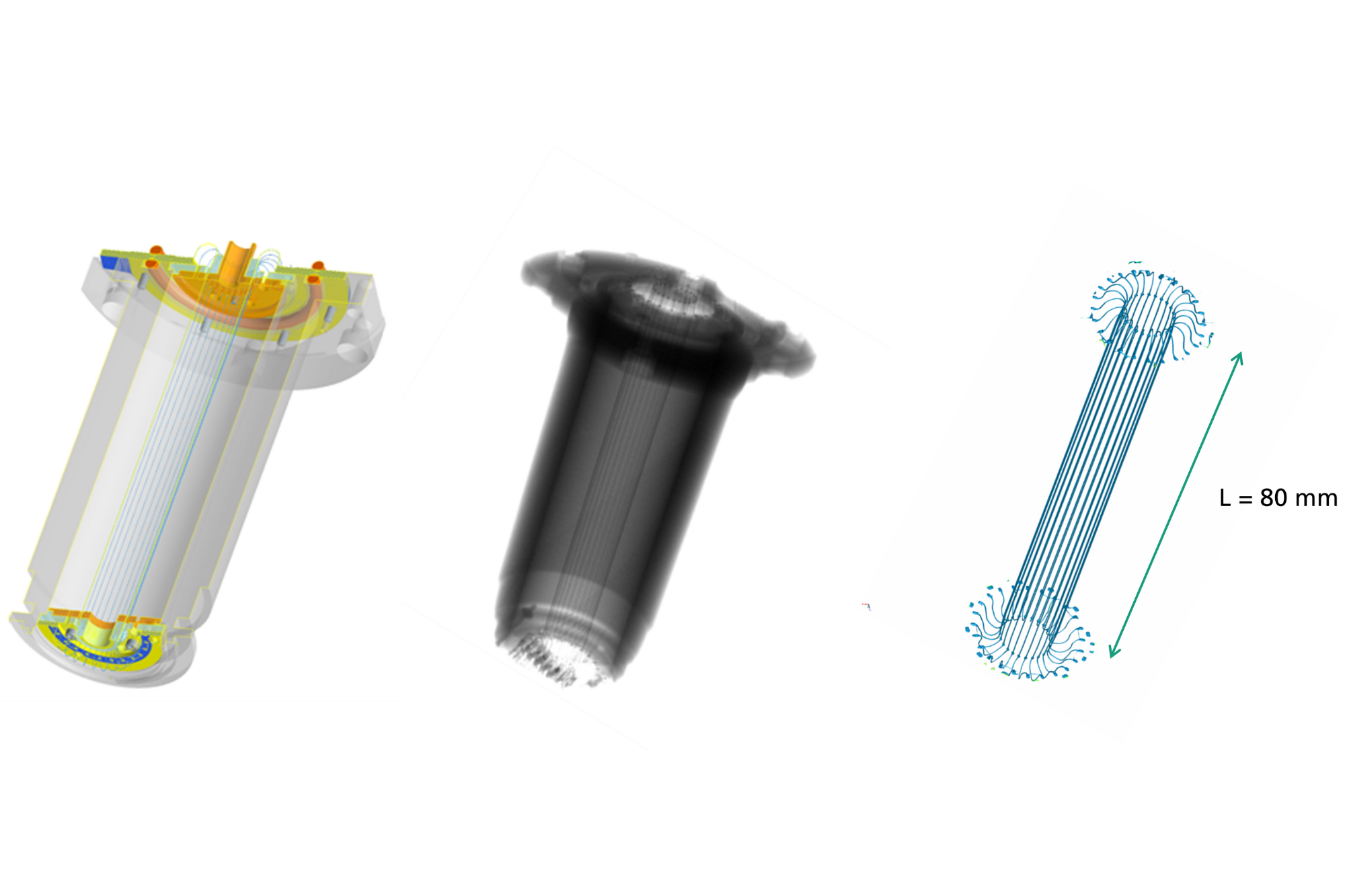

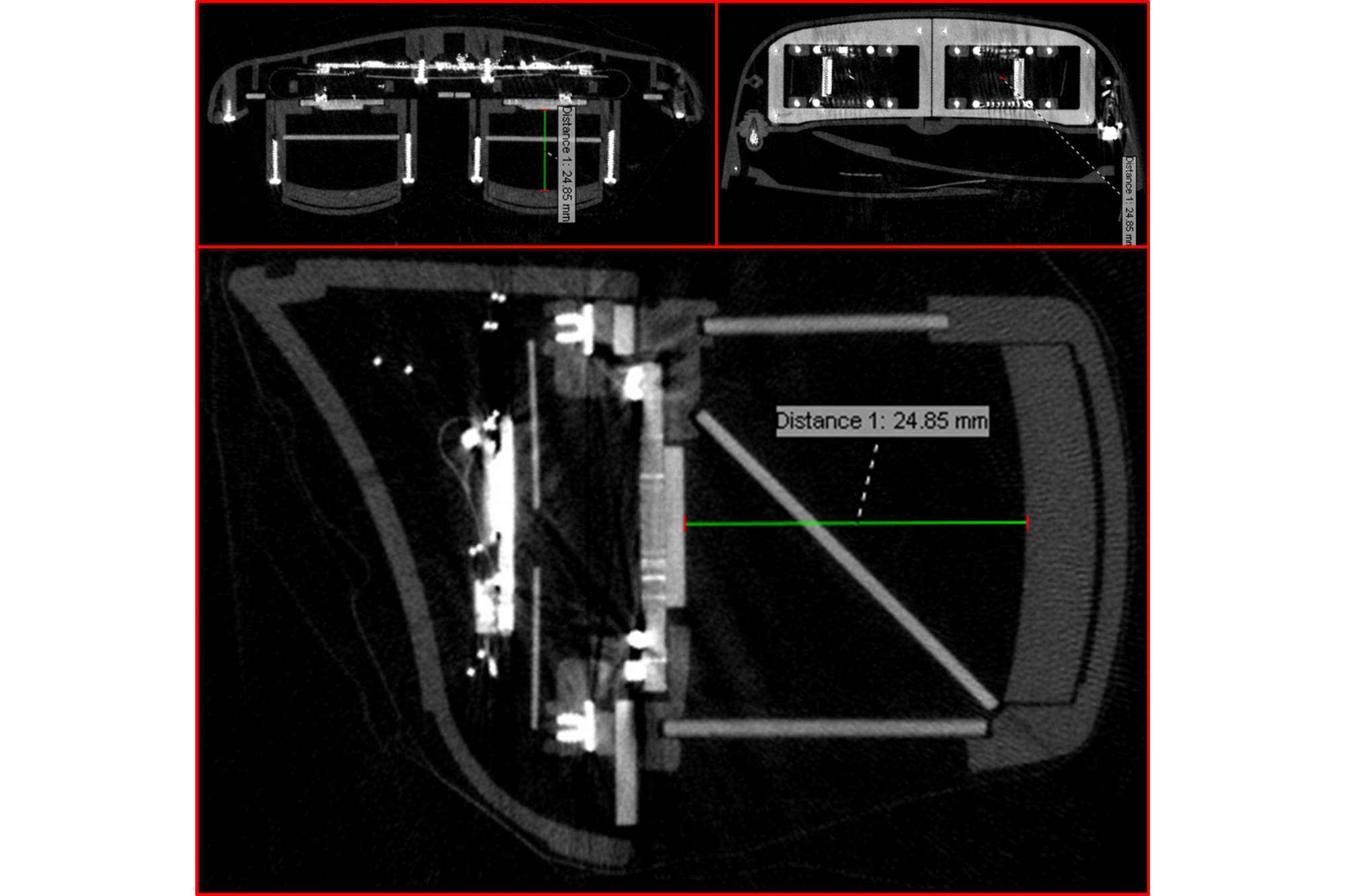

In CT, a measurement object is X-rayed from a large number of angles. A complete volume model of the object can be reconstructed from the radiographic images. Fraunhofer IOF has a CT system of the type v|tome|x from the manufacturer Baker Hughes. Thanks to the cone beam arrangement and two interchangeable X-ray sources, the system achieves great flexibility with regard to the size and material of the measurement objects. The size of the smallest volume element (voxel size) is determined by the position of the measurement object between the beam source and the detector and serves as a benchmark for the metric analysis of the volume model. The resolution limit is ≥ 0.5 μm. In the digital volume models, gray values represent the X-ray absorption in the volume elements. Materials such as plastic, glass, aluminum and steel can thus be distinguished from one another. Based on the gray value transitions between the materials, their surfaces can be determined with sub-voxel accuracy. After the measurement, the complete surface or partial surfaces can be determined in the volume model.

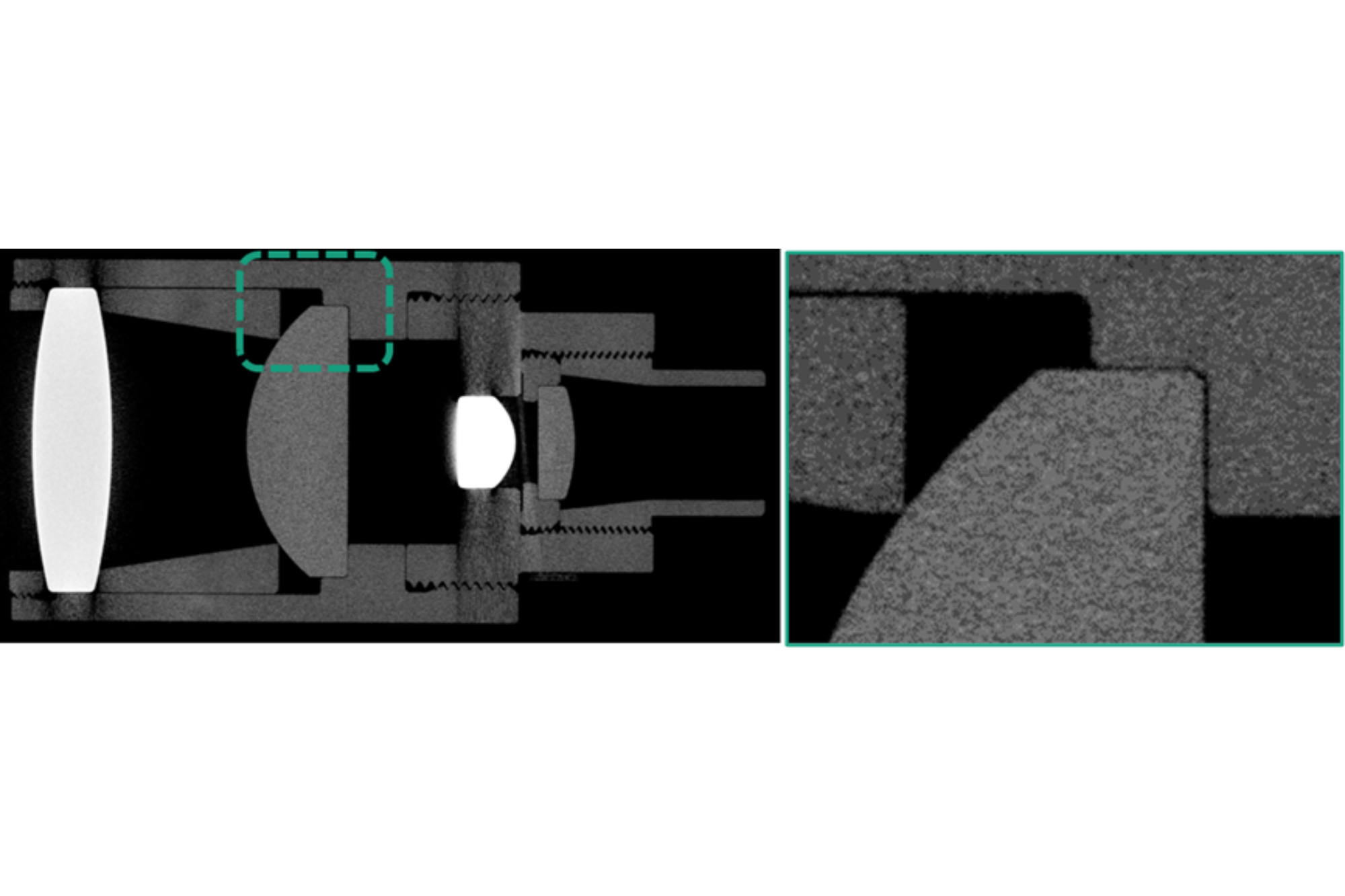

The Fraunhofer Institute for Applied Optics and Precision Engineering IOF develops optical systems for a wide range of applications. The spectrum ranges from tiny illumination units to large imaging mirrors for space travel. By closely combining optical and precision mechanical methods, complex and high-performance optomechanical elements can be designed. However, metric testing of complex components and systems is often problematic. X-ray computed tomography (CT) opens up possible solutions here.