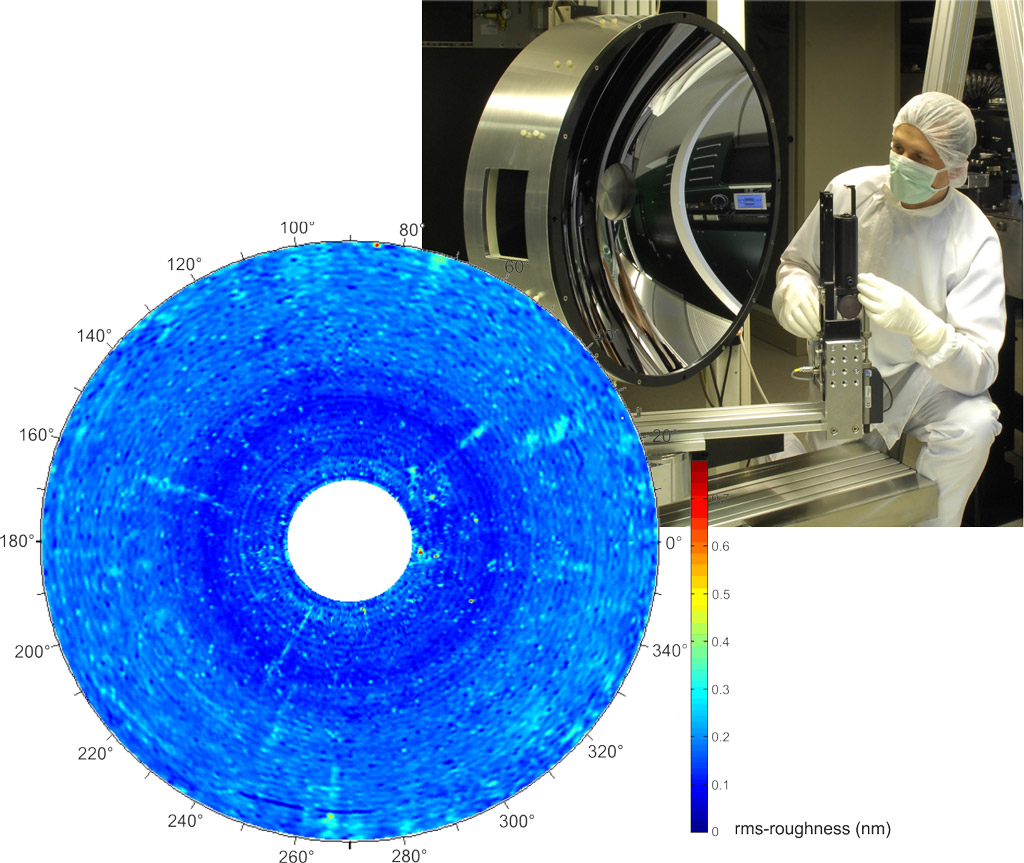

To achieve the required level of imaging quality, the process starts with the design of the optics. Therefore, it is necessary to collect detailed specifications about possible imperfections, including the extent of imperfect points on the surface that is regarded as acceptable and the degree to which any necessary coatings and other factors may influence these values. This data can be provided by Fraunhofer IOF, which develops a wide range of light scattering measurement systems and sensors as well as the corresponding analytical methods and light scattering models. These tools can be used to apply a virtual coating, allowing to make light scattering predictions before production takes place. Besides, they pave the way for performing automated inspection and complete analysis of a surface.

Benefits of the light scattering measurement technique

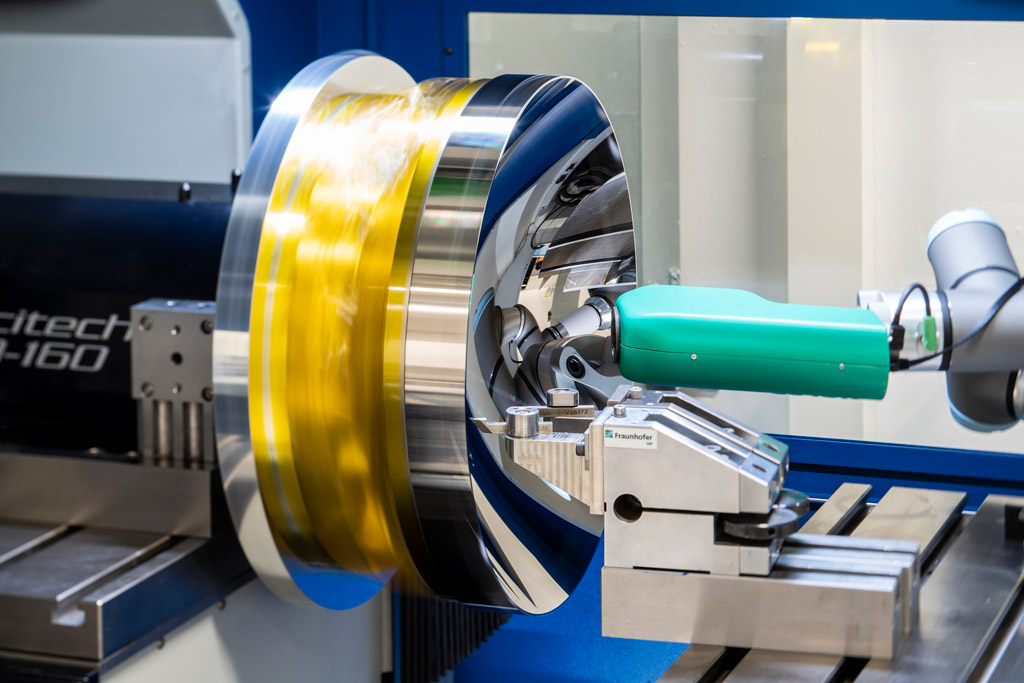

Traditional methods for measuring surface imperfections are expensive and time-consuming. With its high sensitivity, fast and non-contact measurements, light scattering measurement systems offer a tried-and-tested alternative. What’s more, they are not susceptible to vibrations and, unlike traditional methods, making it easier to incorporate in production processes. This allows cost and production times to be optimized. That makes this method a good choice for meeting the ever more demanding requirements of industry and research for optical components. Fraunhofer IOF has already contributed its expertise to manufacturing and optimizing some satellite optics.