Stochastic nanostructures, produced by low-pressure plasma etching, have been applied for antireflection (AR) coatings of polymer substrates for several years. Broadband AR-properties can also be achieved on glass if an organic layer is deposited by evaporation before etching.

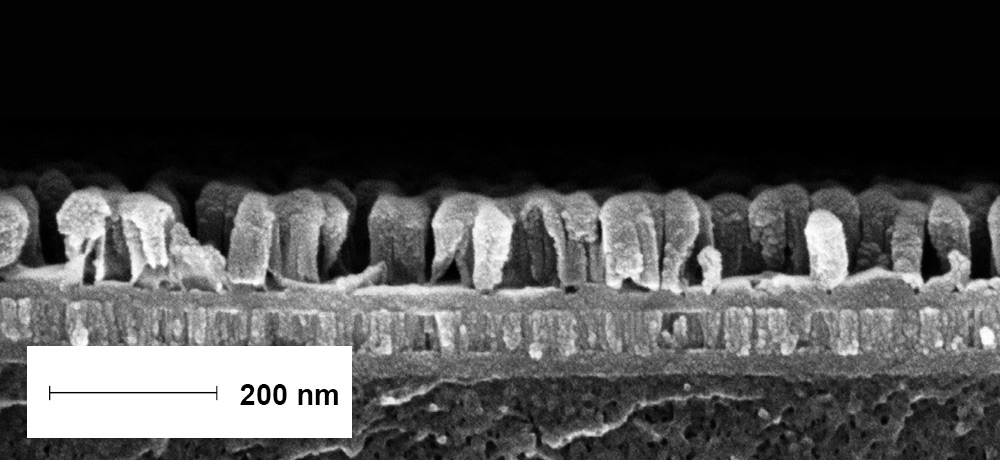

Evaporation processes for organic materials have therefore been developed. Small organic molecules with multiple conjugated bonds such as derivatives of purines und pyrimidines are particularly suitable. An essential step of technology is the top-coating of generated structures with silica.

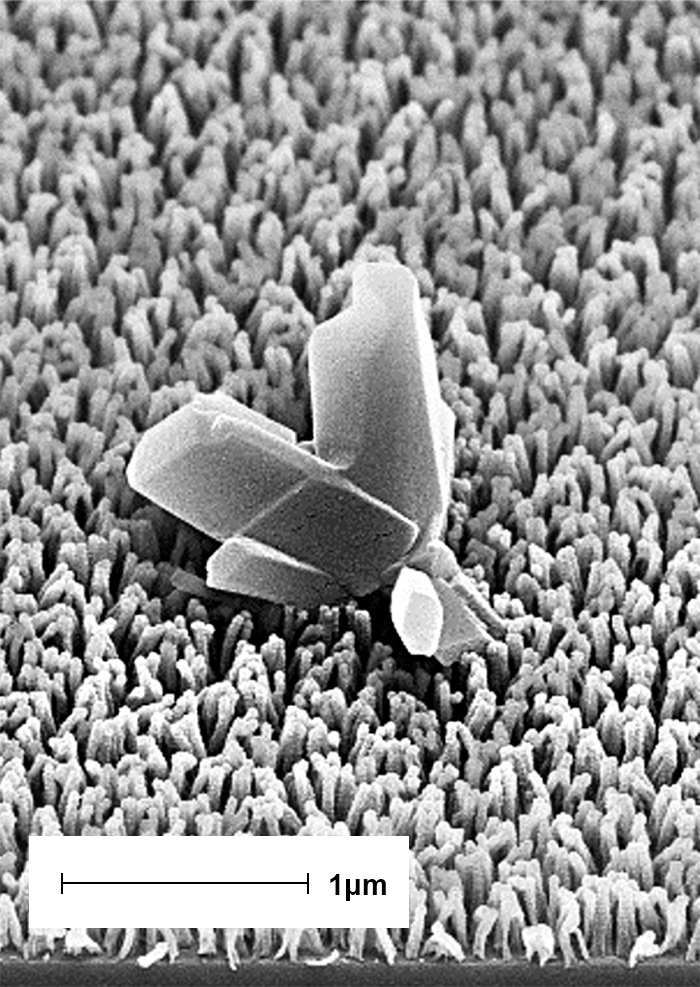

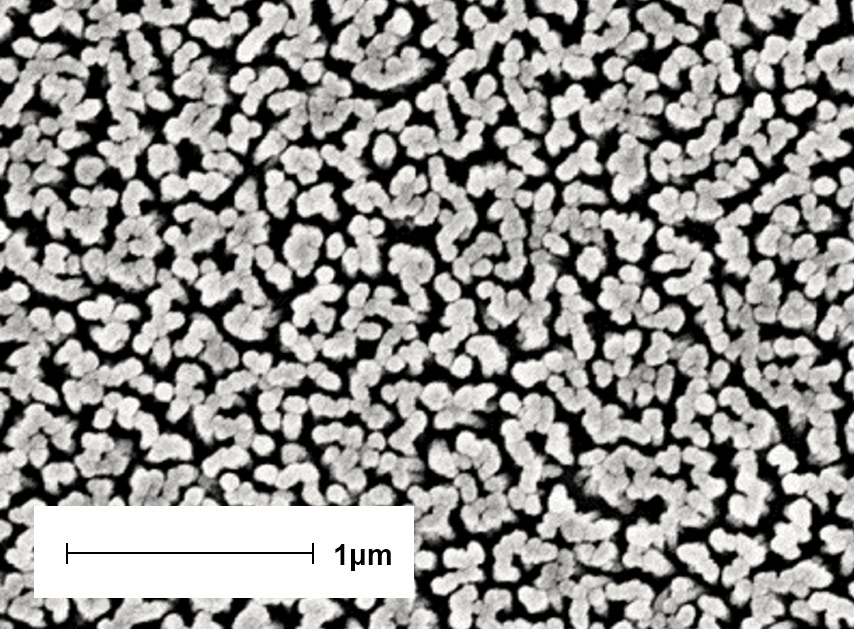

It has recently been shown that plasma treatments as an additional last step are able to create chemical bonds between the oxide and organic groups. Furthermore, a large part of the organic content can be decomposed and removed. As a result, nano-porous hybrid materials are created which contain only traces of organic substances. This opens up a number of new applications. The AR-coatings then show in general a better stability in humid conditions. Some alternative organic precursors can be used which would tend to crystallize at higher humidity (Fig. 1).

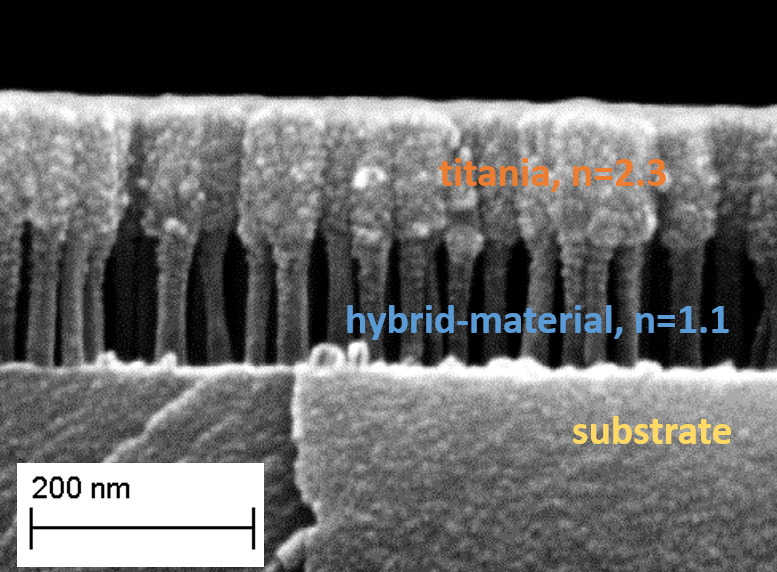

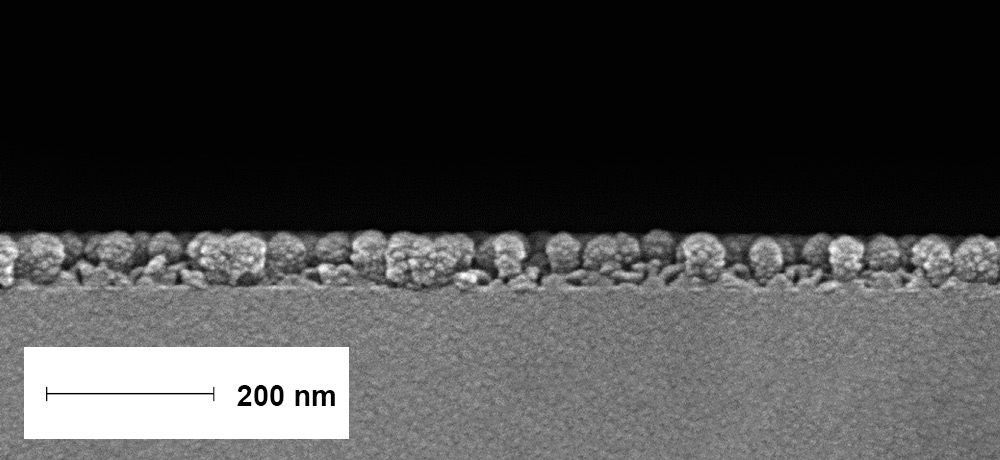

It is now possible to produce AR-coatings on glass and quartz for the ultraviolet spectral range. Additional high-index oxide layers can be applied to cover the structures and to construct quarter wave systems such as dielectric mirrors and filters (Fig. 2). Surfaces with higher mechanical resistance are obtainable by depositing silica layers on top of small structures (Fig. 3a). In addition, these stable small structures are useful to achieve hydrophobic or hydrophilic surface properties.

Recently, a patent which describes the advanced production route has been granted.

Authors: Ulrike Schulz, Peter Munzert, Friedrich Rickelt, Nancy Gratzke