Speciality optical fibers

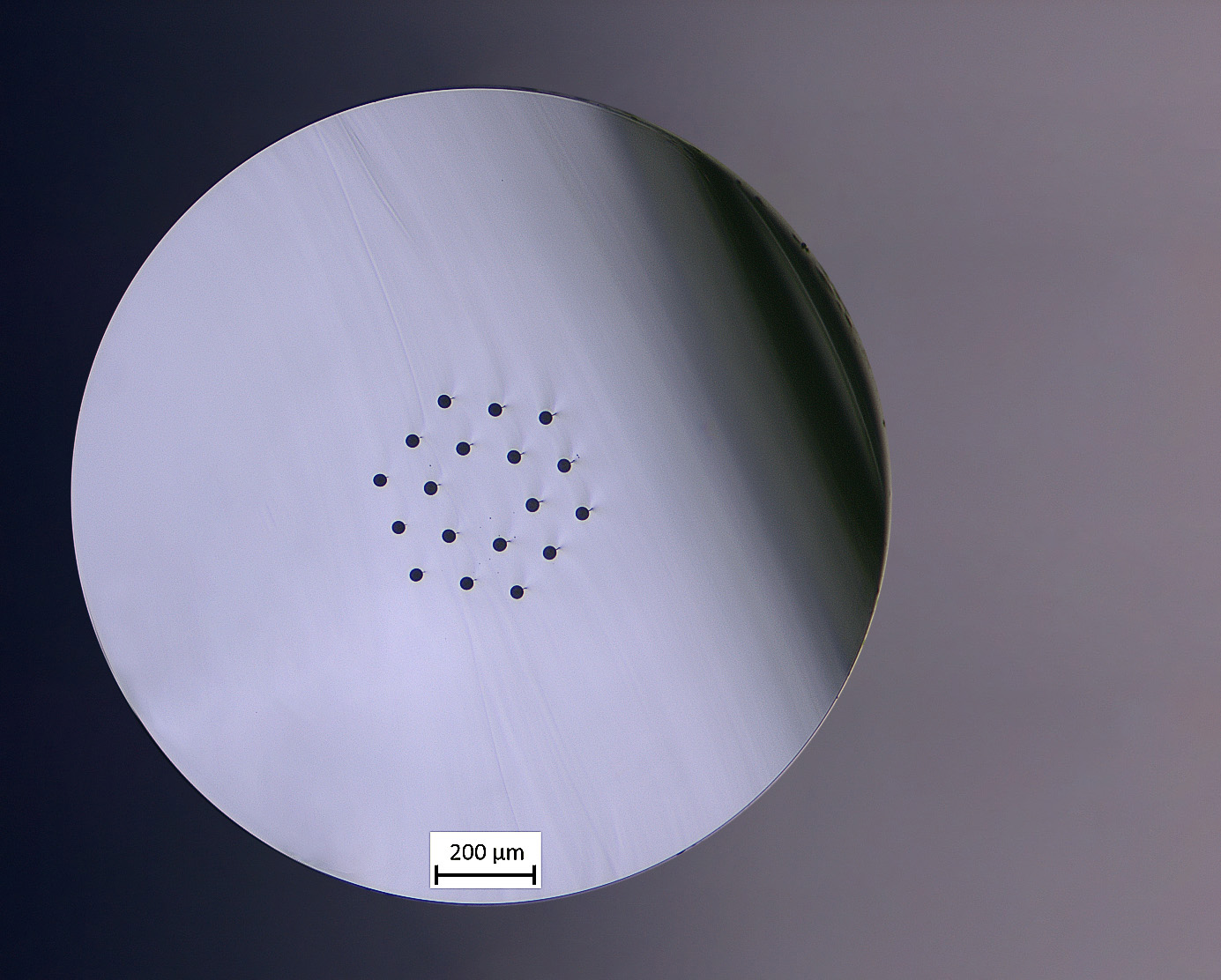

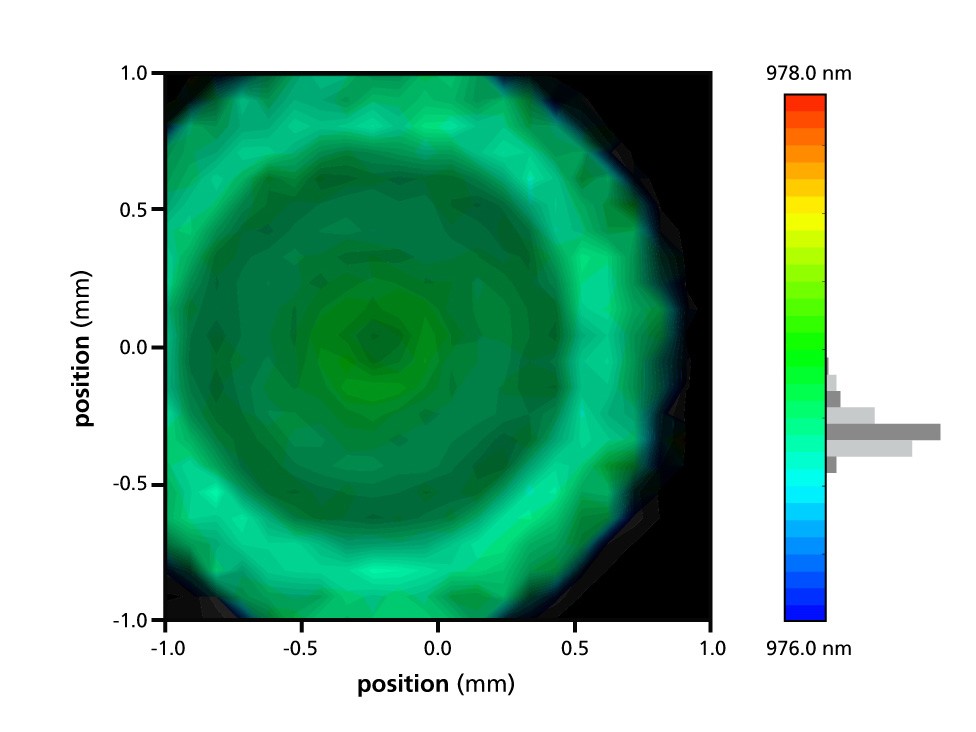

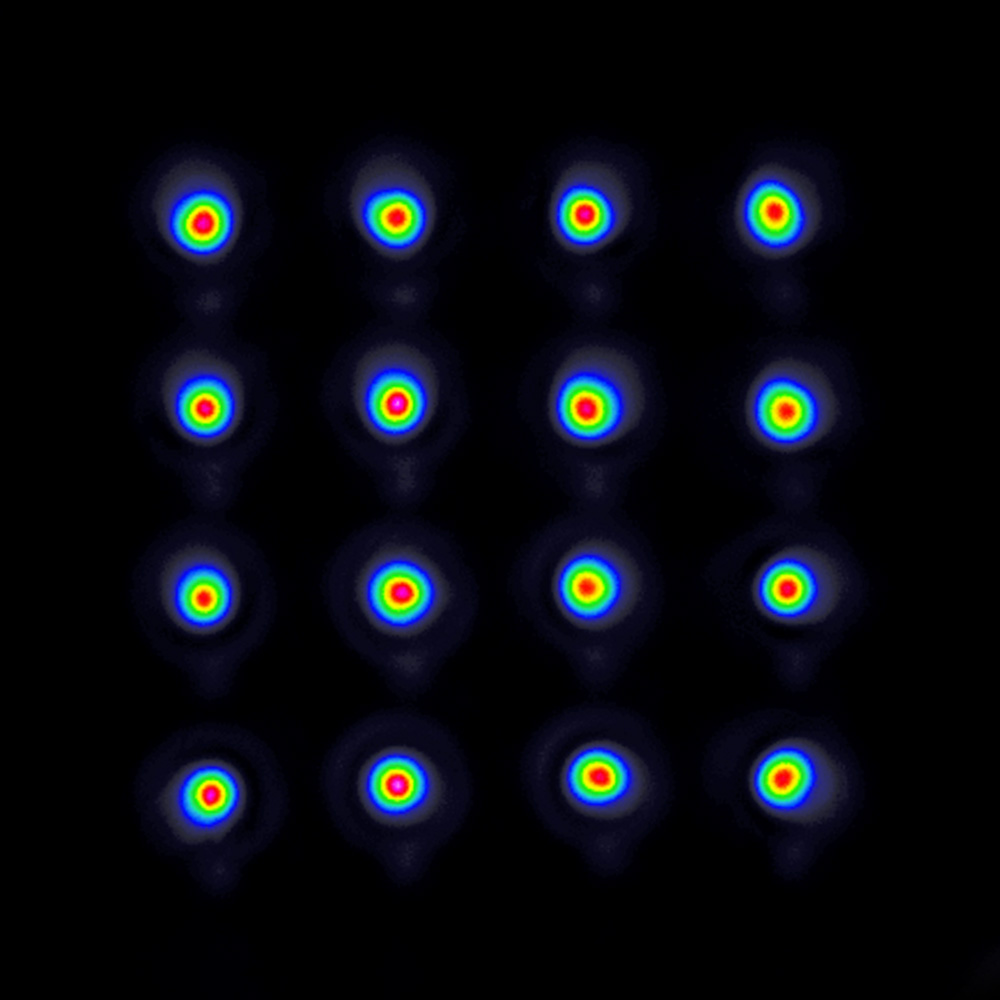

In many areas of modern society, such as telecommuni-cations, industrial manufacturing technology, and medical technology, it is hard to imagine life without glass fibers and their enabling technologies. Their use has already revolutionized several fields of application, such as data transmission in telecommunication, imaging in endoscopic systems, and laser material processing. Fraunhofer IOF has been developing a process chain for the production of speciality fibers since 2012. This year, this process chain was finalized with the completion of the fiber competence center, in particular with the commissioning of the fiber drawing tower. This means that the fabrication of laser-doped materials, preform technology, and fiber drawing technology is now established, thus speciality fibers can be made in-house. With the 16 m high fiber drawing tower for speciality fibers, consisting of two complementary drawing lines, the available options are extended by precise pressure control, the application of optical and mechanical functional layers, and the extrusion of thermoplastics with the produced fibers.