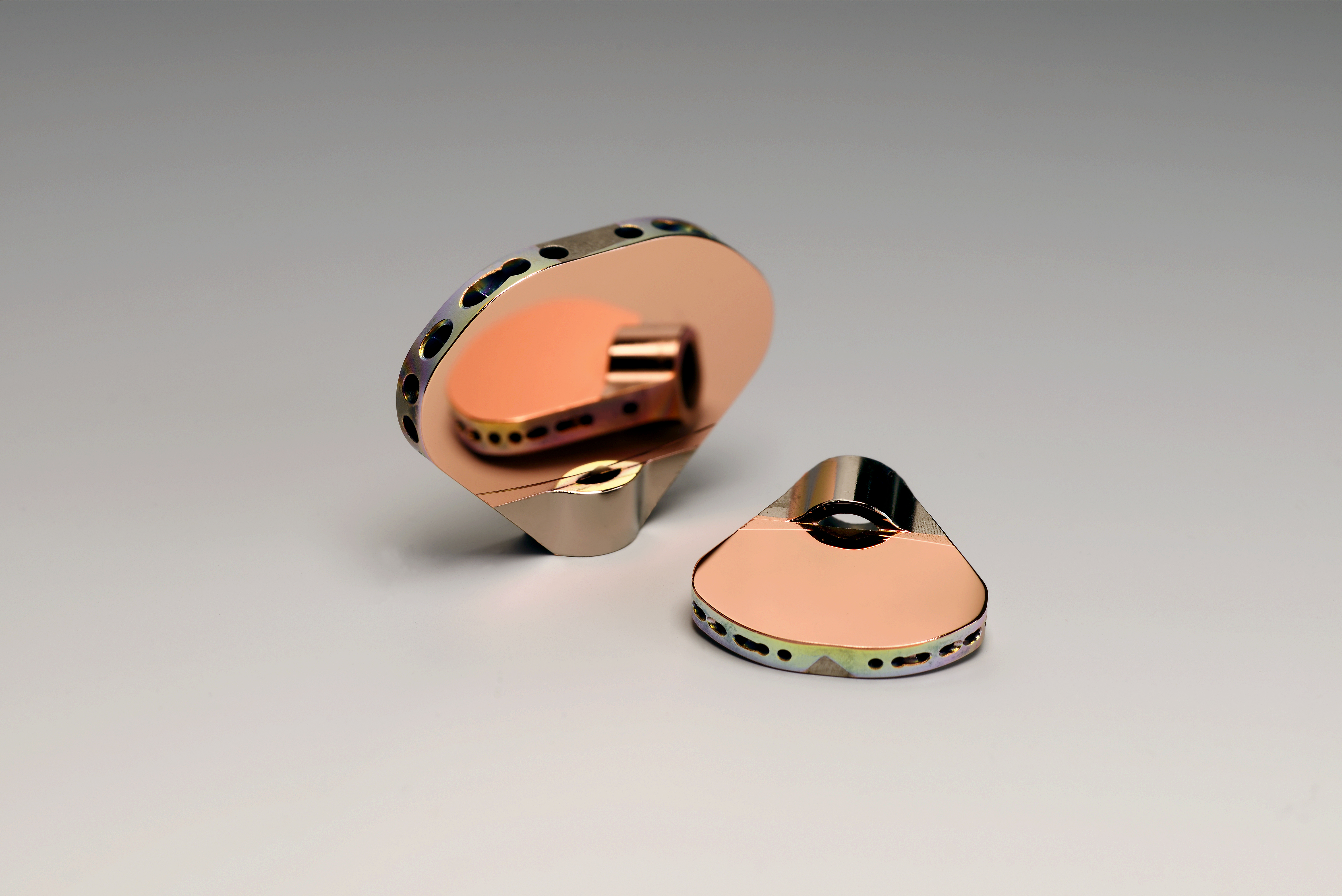

Scanning mirrors for ultrashort pulse-applications must have small mechanical inertia and a small mirror mass to allow very fast and precise positioning of the pulses. Due to the high acceleration, there are stringent demands on the stiffness of the mirrors. Moreover a high quality optical surface is required. Ultraprecise metal mirrors are an attractive solution that fulfils these requirements. In addition, the easy and cost-effective manufacturing technology is an important advantage in comparison to alternatives such as glass-, glass-ceramics-, and ceramic-mirrors.

At Fraunhofer IOF scan mirrors were manufactured from AlSi-composite material. Ultraprecise AlSi based lightweight mirrors with high surface quality can be manufactured by applying electroless deposited nickel (NiP) platings in combination with diamond turning and polishing. A surface roughness lower than 1 nm rms was achieved after polishing. The amorphous NiP and the AlSi alloy are thermally matched better than 0.5 ppm.

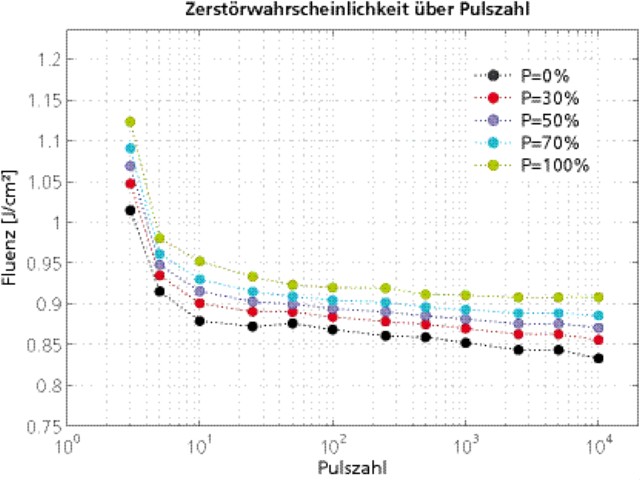

In order to achieve high reflectivity values in combination with a high laser damage threshold (LIDT) suitable for scan mirrors, the high reflectivity of metal-layers was enhanced by dielectric HfO2/SiO2 stacks. These coatings are considerably thinner than all dielectric high-reflective coatings and have sufficiently high damage thresholds above 1 J/cm2@8ps. The damage measurements were performed at a wavelength of 1030 nm.

Authors: Mark Schürmann, Stefan Risse, Helena Kämmer, Sandra Müller, Ralph Schlegel