Motivation

Polymethylmethacrylate (PMMA) is the preferred polymer material for precision optical applications. It shows excellent optical properties and can be injection moulded with low costs to complicate components like aspheres. For many applications the spectral transmission and scratch resistance of PMMA have to be improved by coatings. But, because of the danger of plasma damage during vacuum deposition processes, optimized process parameters are required to deposit coatings with high adherence to the substrate.

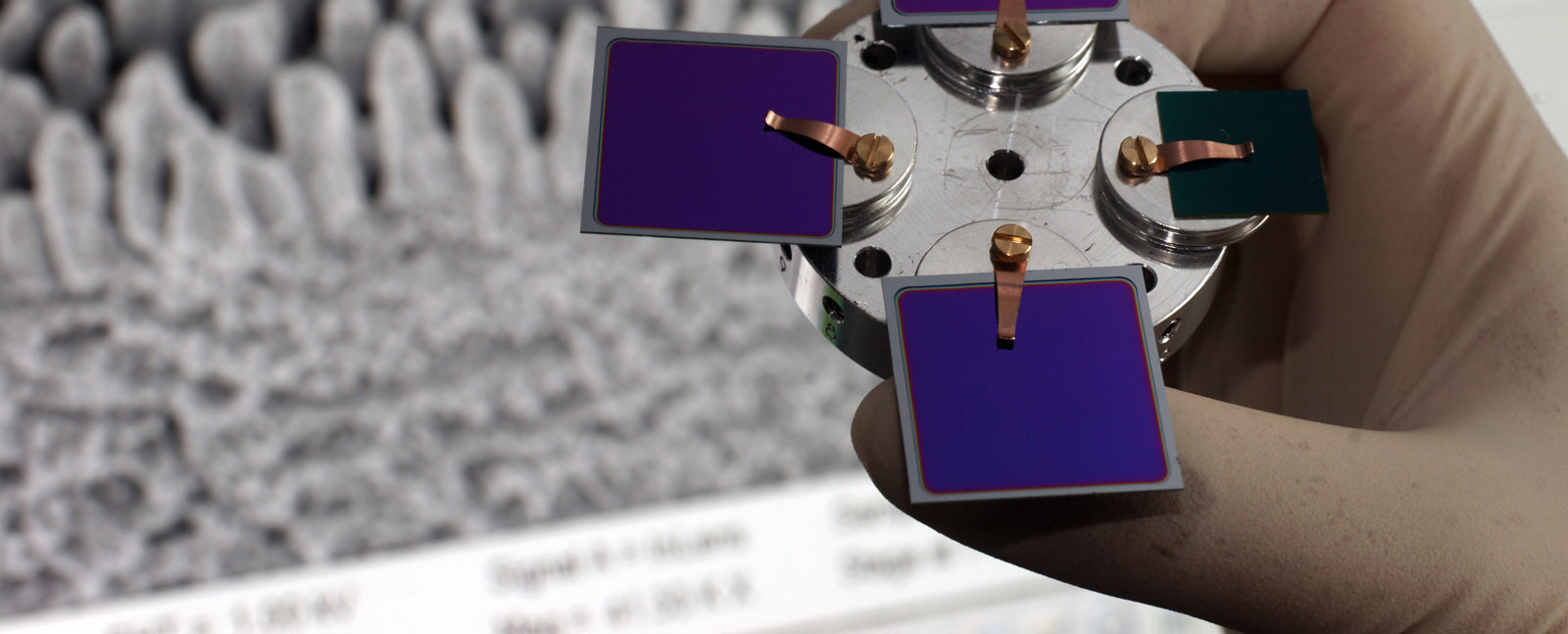

Our solution

Essential part of all coatings is a UV-protective layer which has to be deposited according to a patented technology (DE10201492B4). Coating designs for conventional thin antireflective coatings and for more durable AR-coatings AR-hard®are available. Plasma-ion assisted deposition (Plasma-IAD) can be applied by using customized parameters.

Properties

- Reflection (420-670 nm) < 1,5 %

- Adherence according to ISO9211-02-02

- Environmental durability according to ISO9022-2:

- - dry heat 16 h at +70 °C

- - cold 16 h at -40 °C

- - humidity 16 h at +55 °C, 95 % R.H.

- Coating AR-hard®: abrasion according to ISO9211-01-04: eraser test, force 10 N, > 40 rubs

Our work

Please ask for sample coating of your PMMA optical parts for a desired optical performance. A license to use the patented technology can be offered.