Motivation

Antireflective nanostructures can be produced on many polymers by plasma etching. The structure formation occurs self-organized or after depositing of a thin layer. Typically the modified surfaces are soft and damageable. Additional thin layers are useful to protect the surfaces mechanically and to modify the wetting behaviour in various ways.

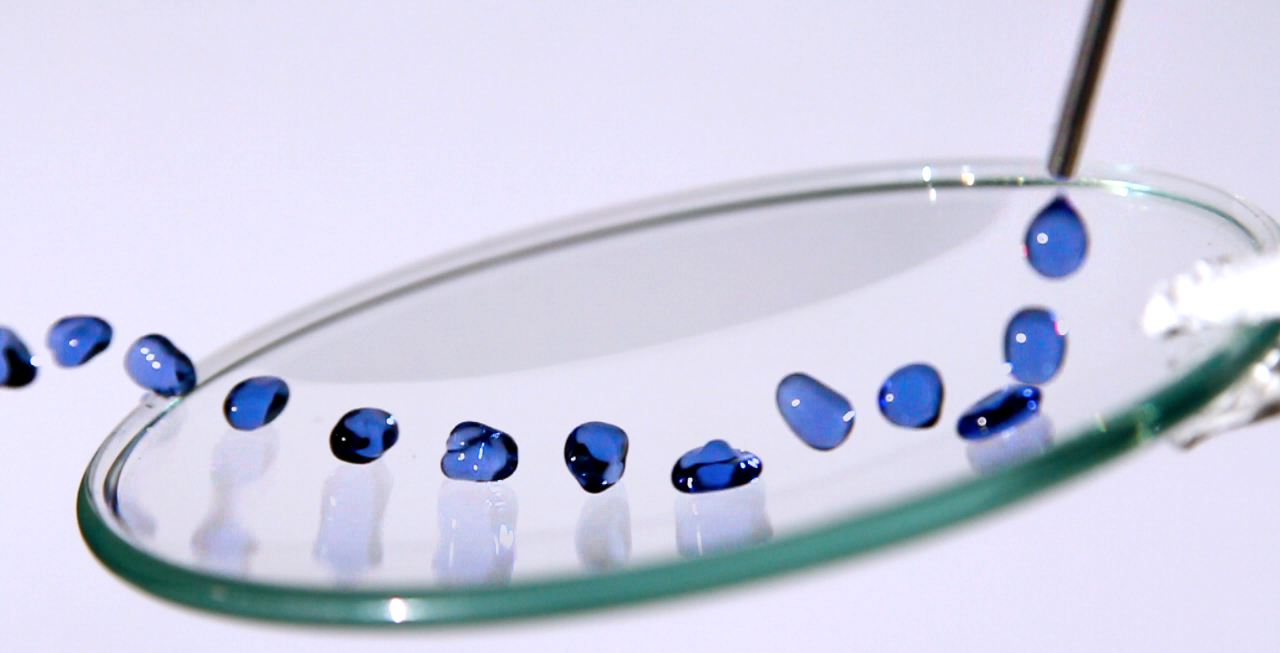

Easy cleanable hydrophobic and superhydrophobic surfaces

Superhydrophobicity can be achieved by depositing layer systems which comprise at least a fluoroalkylsilane component on top of plasma-etched polymers (i.e. PMMA). The procedure is useful for removing fingerprints easily.

- PMMA: cleaning with flowing water/detergent

- Zeonex: cleaning with cloth/ethanol

- Contact angle: > 150°

- Water drop roll-off angle on PMMA: < 10°

Hydrophilic surfaces providing antifogging properties

Thin oxide layers are useful for creating an antifogging effect on surfaces with antireflective structures. In addition, antifogging and antireflection can be achieved simultaneously by the direct plasma-etching of water absorbing polymers, i.e. antifogging lacquer SeeklearTM (Exxene Corp.).