Ultrashort pulse lasers with pulse duration in the range of a few picoseconds or femtoseconds show great use potential for the highly-precise structuring of a wide range of materials, in particular metals.

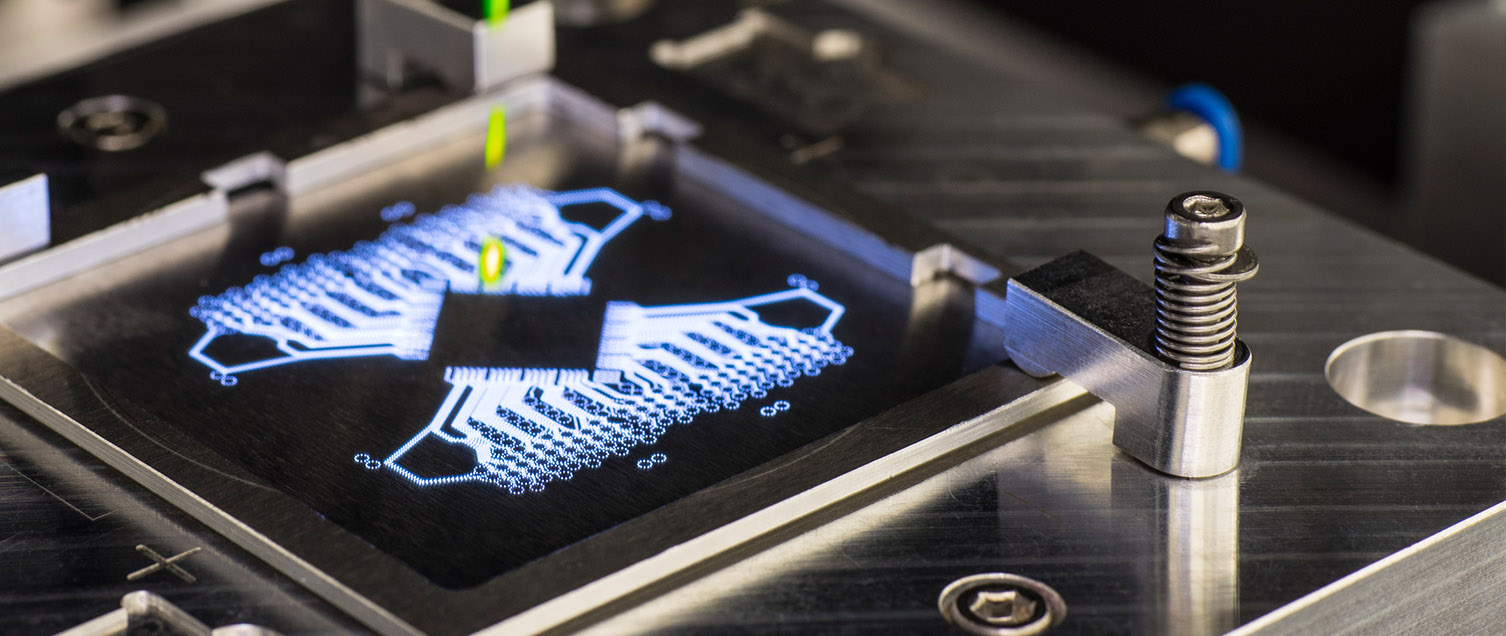

Due to the short energy deposition in one time range below the thermal relaxation time, surface removal – with suitable parameters – can be achieved with practically no mechanical or thermal damage (“cold” ablation). This generates minute structures which are only defined by the optical properties of the laser beam. The brief pulse duration with moderate pulse energies means a very high laser intensity. This enables the utilization of intense non-linear absorption processes. As a result, practically all materials, whether transparent or opaque, can be processed. In addition, specific three-dimensional structures are realizable in bulk.

The brief process times required by the production process can therefore be preferably realized with powerful ultrashort pulse laser sources. The fiber-based ultrashort pulse laser systems developed at Fraunhofer IOF offer high pulse repetition frequencies with high performance and outstanding beam quality. This results in an increase in processing speed and productivity.

Competencies at Fraunhofer IFAM encompass:

- Extensive knowledge of laser-matter interaction for process optimization

- Surface structuring and modification

- Processing of thin-film systems, e.g. for photovoltaic applications

- Precision drilling, e.g. drilling holes with high aspect ratio