Coating technologies and freeform optics: Fraunhofer IOF at the Photonics West 2020

The Fraunhofer Institute for Applied Optics and Precision Engineering IOF will once again be presenting new state-of-the-art developments at North America’s largest photonics trade fair, including coating technologies and metal mirrors for space applications. A special highlight this year is the public workshop of the growth core fo+ [freeform optics plus] all around the topic of freeform technologies. Besides presentations by regional partners, the Fraunhofer IOF will present its competencies in the fields of metal optics and additive manufacturing. Admission is free.

When more than thirty companies and research institutions from Jena and the surrounding area make their way to San Francisco, this can only mean one thing: Photonics West is back on the agenda. From February 1st to 6th, 2020, the optics region will show what it can do at North America’s largest photonics trade fair. The Fraunhofer IOF Institute of Applied Optics and Precision Engineering IOF from Jena will be among the approximately 1300 exhibitors. The institute is represented at the German Pavilion with a variety of photonic technologies.

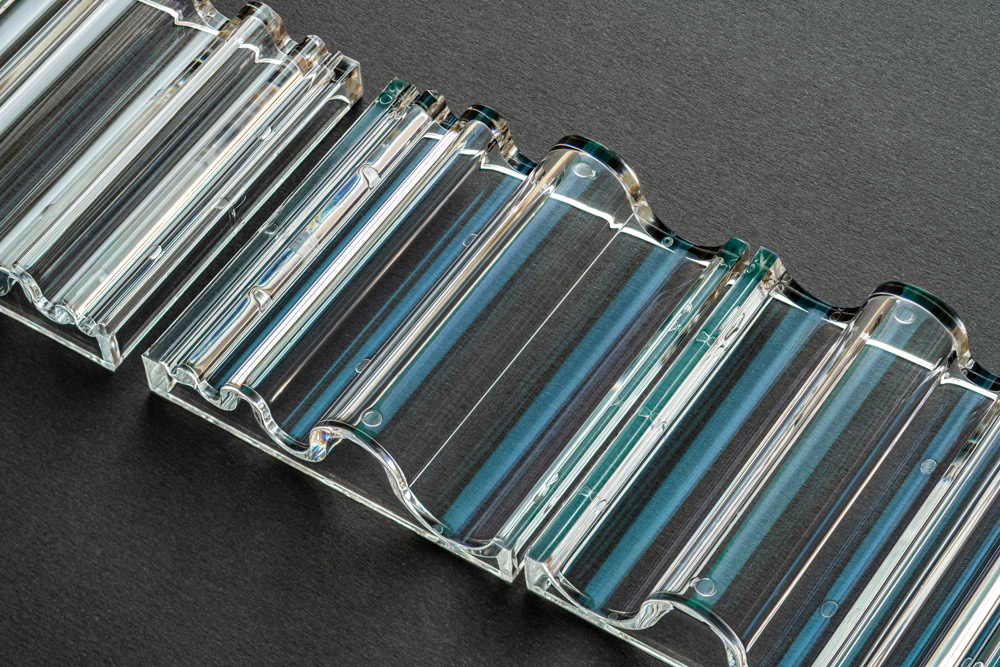

Coatings on surfaces of any shape

Among other things, new coating technologies will be on display. Atomic layer deposition (ALD) is currently a widely used technique in semiconductor manufacturing, and for improving the performance of solar cells or batteries. By ALD, optical layers are precisely applied to any shape of optics and nano-/microstructured components. Moreover, the thickness and composition of the films can be controlled by ALD down to sub-nanometer precision. Interference multilayer systems such as antireflective coatings, dichroic mirrors, and band-pass filters with exceptional uniformity are presented on domes and strongly curved lenses.

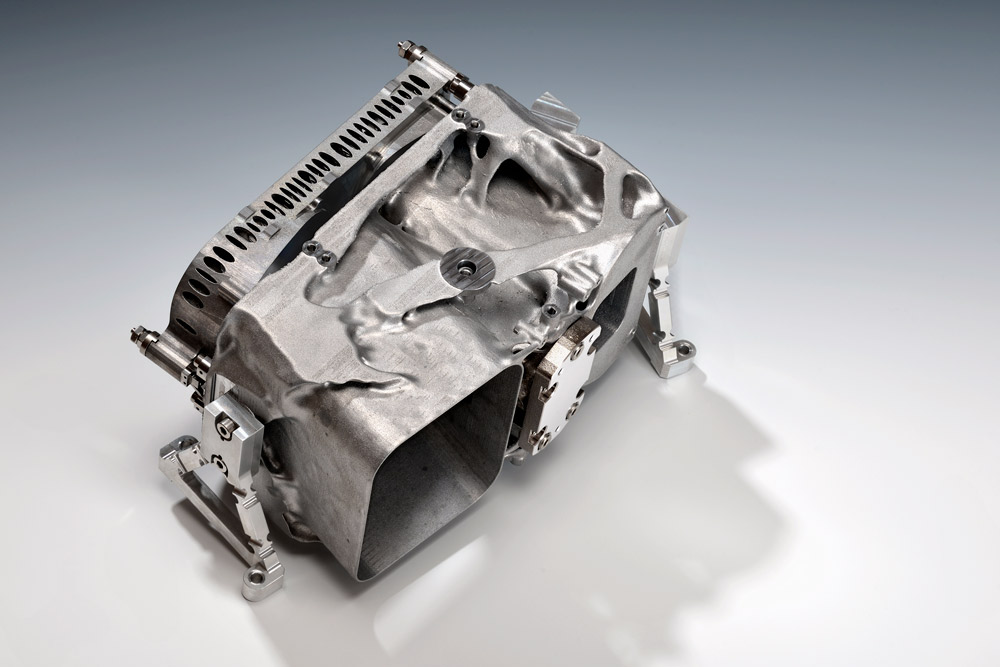

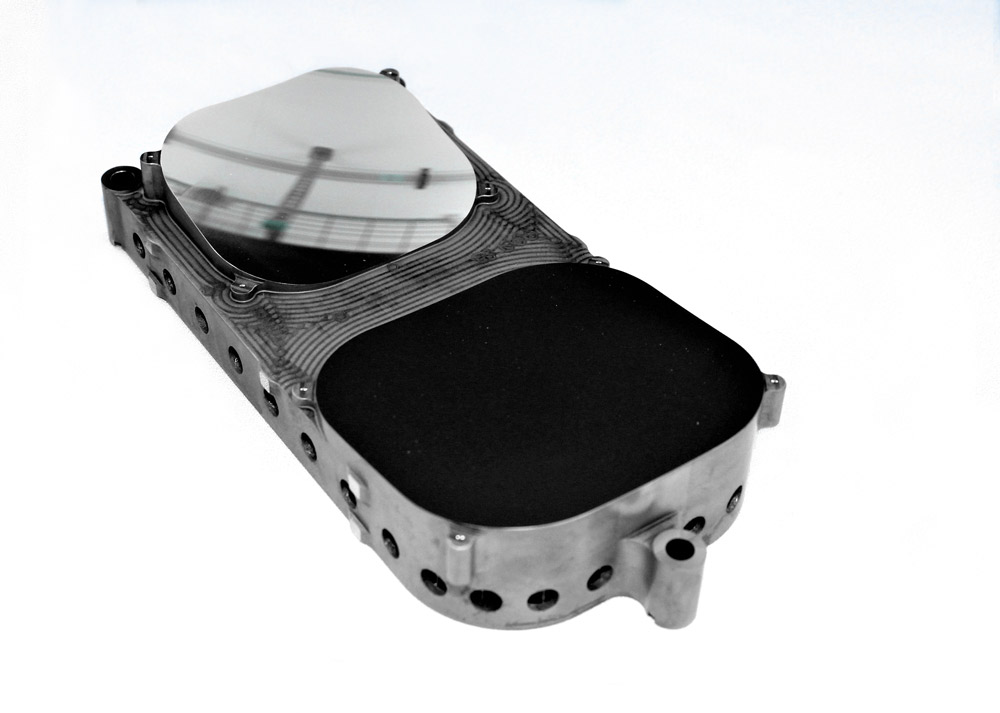

Additive manufacturing of optical freeform mirrors

Precision optics from the 3D printer - this sounds simple, but it requires the development of a complex process chain. In additive processes such as Selective Laser Melting (SLM), a metal powder is remelted by the laser along a predetermined contour in the powder bed. The process is repeated layer by layer until a complete metal workpiece is obtained, which can be reworked and tempered ultra-precisely for optical applications. Metal optics are still often manufactured conventionally, but additive processes offer several advantages and, besides increased design freedom, enable extremely lightweight construction and can connect different optical elements in a single lightweight structure. The adjustment effort can be significantly reduced and significant mass savings with high stiffness can be achieved.

The experts from Fraunhofer IOF will present conventionally and additively manufactured precision optics, including a topology-optimized, additively manufactured TMA mirror system with a double-walled frame construction for telescope applications, in which a mass reduction of about 70% has been achieved.

You will find us and our exhibits from February 1st to 6th, 2020 in the German Pavilion (Moscone Center), booth 4545-21.

Workshop »FREE your mind – FORM your optics«

Another highlight this year is the public workshop of the regional optics growth core fo+ [freeform optics plus], whose project partners are working on the development and marketing of innovative freeform optical systems, including applications in laser material processing, image processing, and automotive sensing. Exchange ideas and learn more about the unlimited possibilities of freeform optics - its design and materials, up to excellent coatings and production possibilities. The event begins on February 4th at 2:00 pm (Public Demo Area, Hall E/F). Admission is free.

Lectures

The world's leading trade fair is embedded in a scientific conference, in which researchers

from the Fraunhofer IOF will participate with many lectures, among others on

novel applications of ultra-short pulse lasers and laser sources. The results were obtained

within the Fraunhofer Cluster of Excellence CAPS ("Cluster of Excellence Advanced

Photon Sources"):

February 3th, 2020 | 1:30 – 2:00 pm

7.2-kW ultrafast fiber laser based on coherent combination

Michael Müller (Institute for Applied Physics, FSU Jena)

Session: Coherent Combination of Fiber Lasers

February 4th, 2020 | 3:30 – 4:00 pm

Soft x-ray high order harmonic generation driven by high repetition rate ultrafast thulium-doped fiber lasers

Martin Gebhardt (Institute for Applied Physics, FSU Jena)

Session: Thulium Doped Fiber Lasers and Amplifiers II

February 5th, 2020 | 11:10 – 11:30 am

The sensitivity of the mode instability threshold to different types of intensity noise

Christoph Stihler

Session: Mode Instability/Stimulated Thermal Rayleigh Scattering