Your partner

We work closely with companies, institutions or other organizations to develop innovative solutions in the field of 2D, 3D and multimodal sensing, image processing and AI.

1. Research and development:

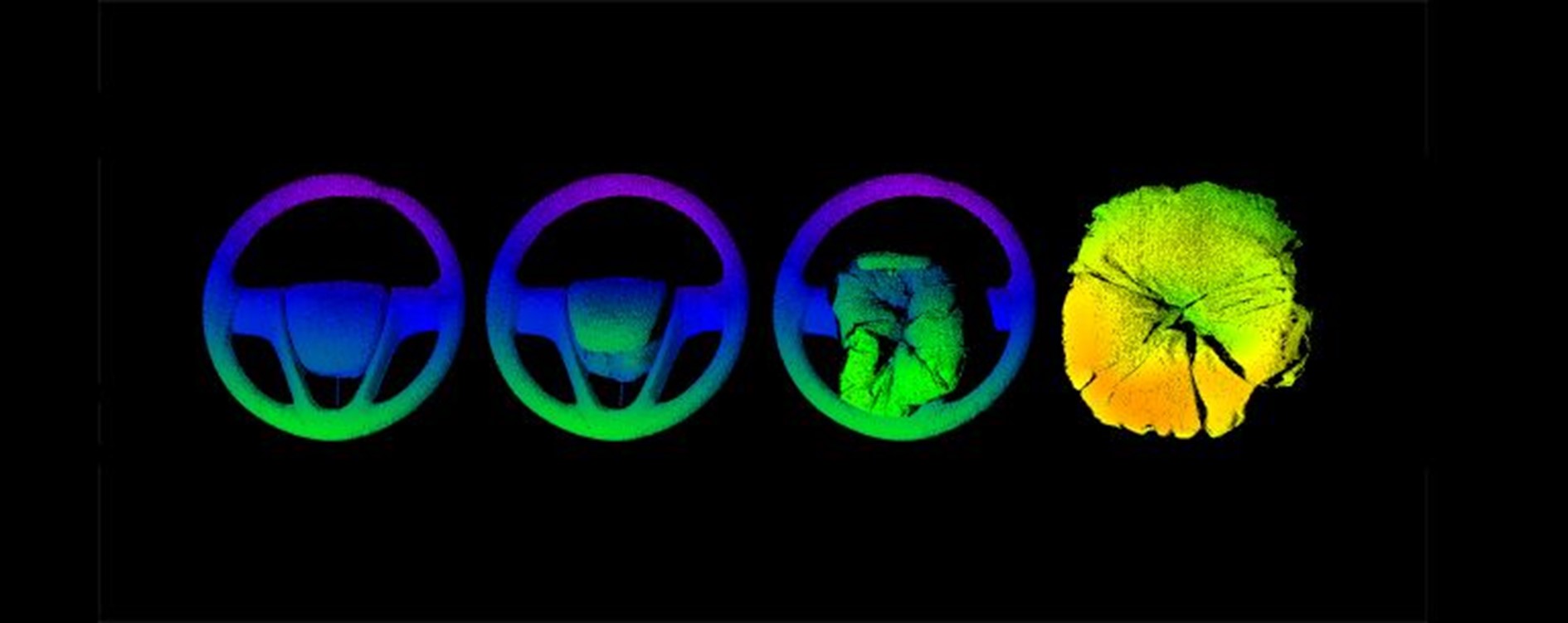

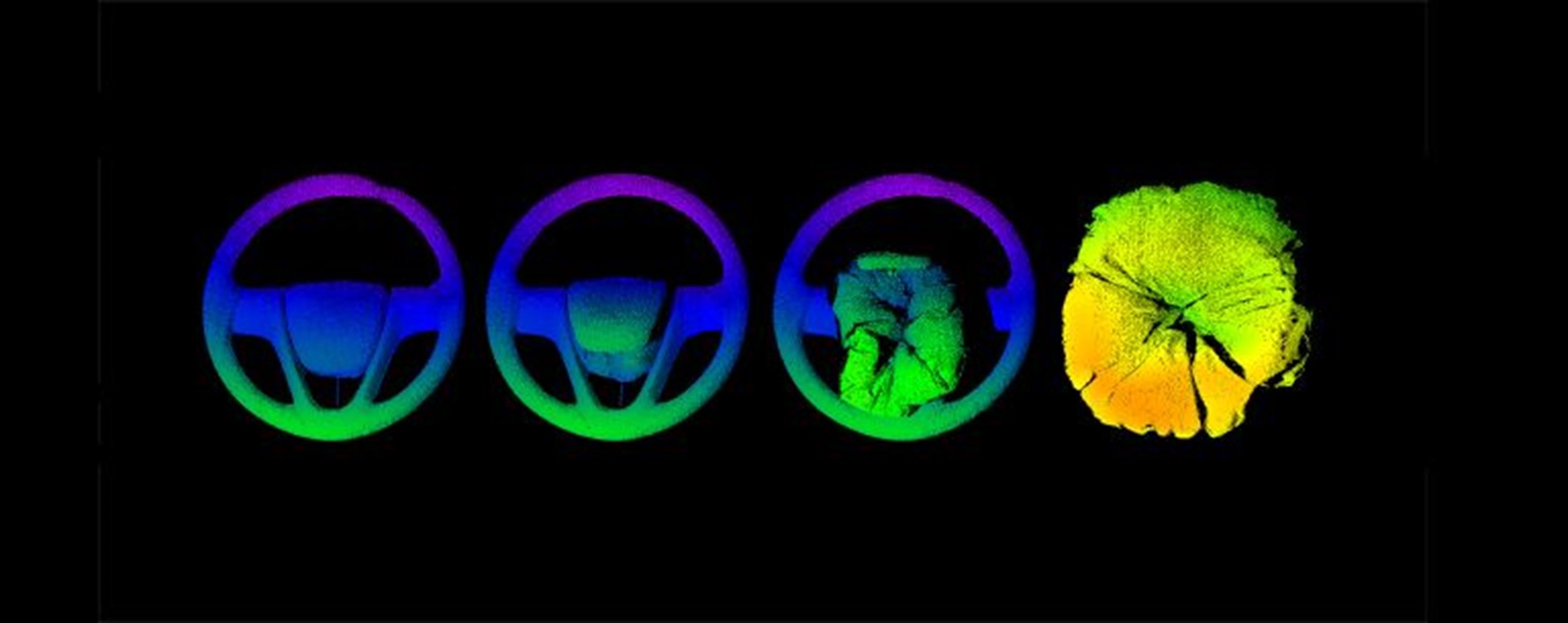

As your partner, we rely on comprehensive research and development work to study and develop new technologies, methods and algorithms in the fields of 2D, 3D and multimodal sensing, image processing and AI. Our approach includes not only identifying challenges and conducting experiments, but also the targeted development of prototypes and thorough evaluation of solutions to ensure they meet our customers' high standards.

2. Consulting and expertise:

As a partner, we offer comprehensive consulting services and in-depth technical expertise in 2D, 3D and multimodal sensing, image processing and AI. Our service includes a thorough evaluation of existing technologies, a precise analysis of your specific requirements and the selection of the optimal sensors and imaging systems that fit your application goals precisely. We support you not only with integration into your system landscape, but also with ongoing optimization to achieve the highest possible efficiency and performance.

3. Adaption and integration:

We specialize in adapting existing imaging systems and sensors precisely to the specific requirements of our customers and seamlessly integrating them into existing systems or processes. Our tailor-made solutions include the development of user-defined interfaces, the precise calibration of sensors and the adaptation of algorithms for optimized data evaluation.

4. Prototype development:

One of our particular strengths is the development of prototypes of imaging systems or sensor solutions to demonstrate their functionality and performance. This allows our partners and customers to test the technology in a real-world environment and provide valuable feedback. Our iterative development process ensures close alignment with customer needs to create tailor-made solutions that offer real added value.

5. Evaluation and validation:

We conduct evaluation and validation studies to assess the performance and reliability of imaging systems and sensors. We follow the most up-to-date standards and industry-specific requirements. Our process includes detailed testing under various conditions, careful analysis of data sets and comprehensive assessment of results to ensure that systems perform optimally under real-world conditions.

6. Technology transfer:

As a committed research and development partner, we support our partners in the transfer of research results into practice. This includes not only the training of employees in the form of customized technical workshops and webinars, but also targeted support in the certification of products and systems according to internationally recognized standards. We accompany the rollout of innovations and ensure that the implementation runs smoothly.