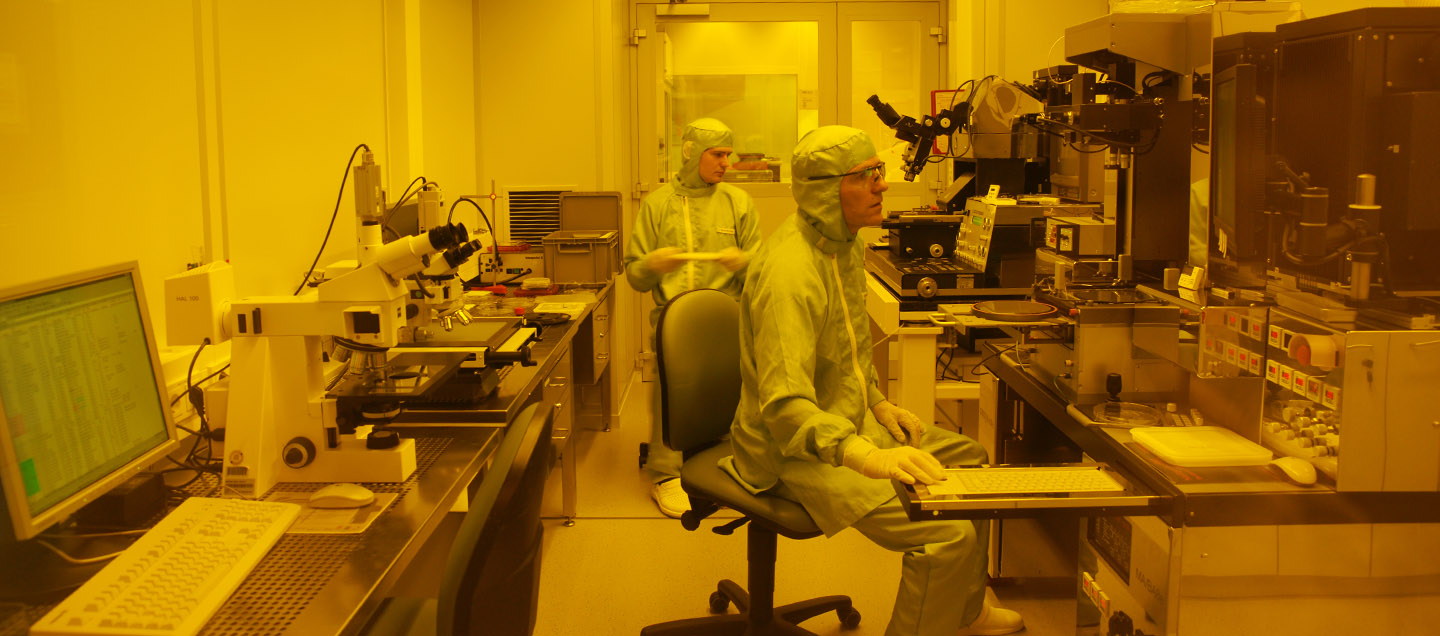

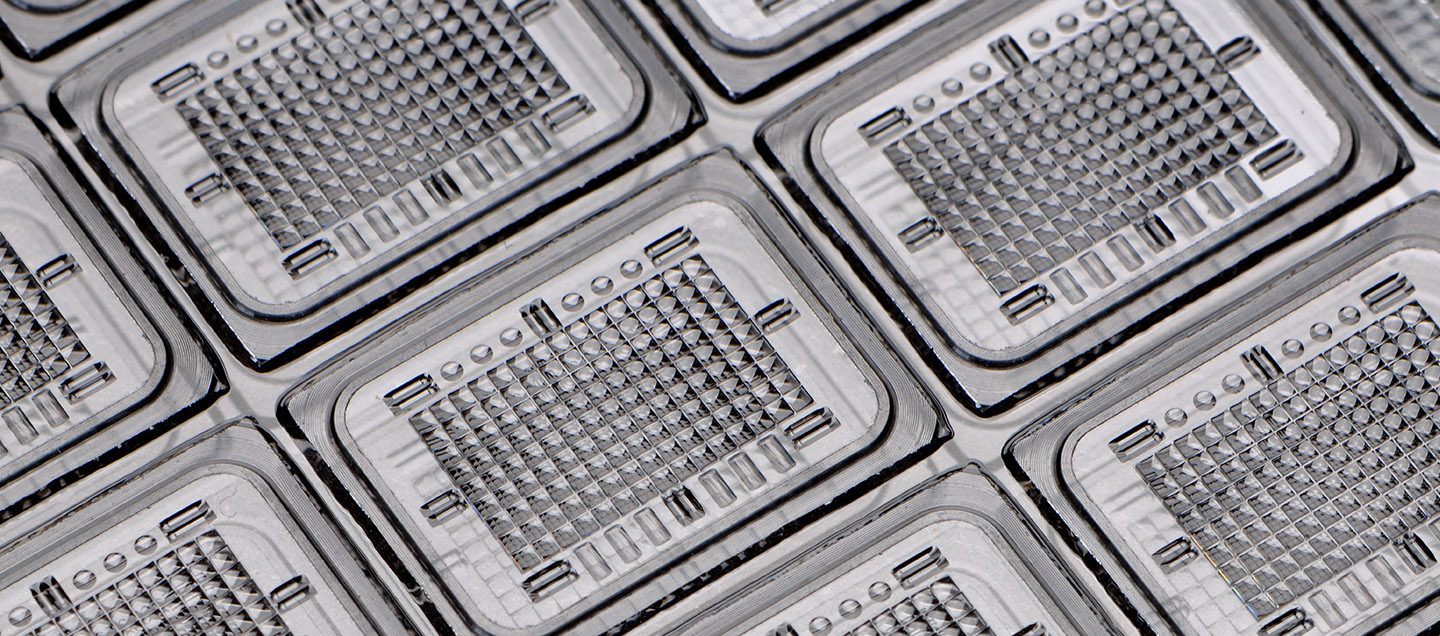

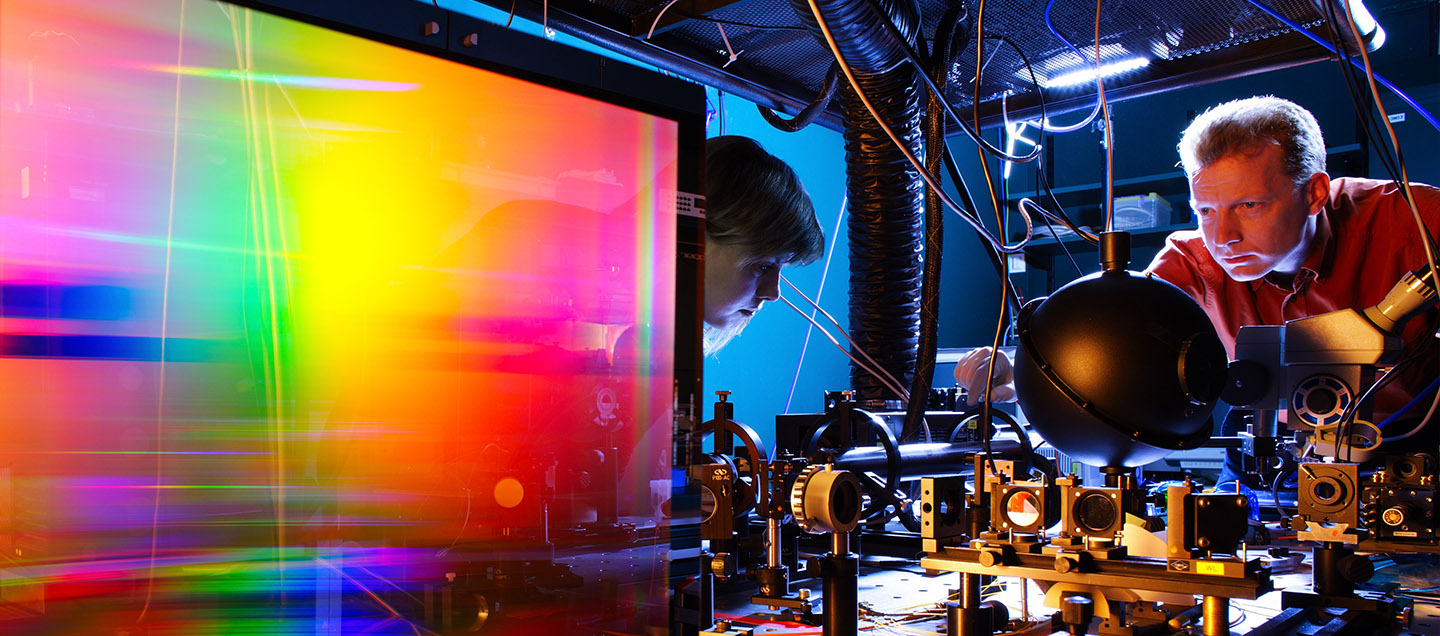

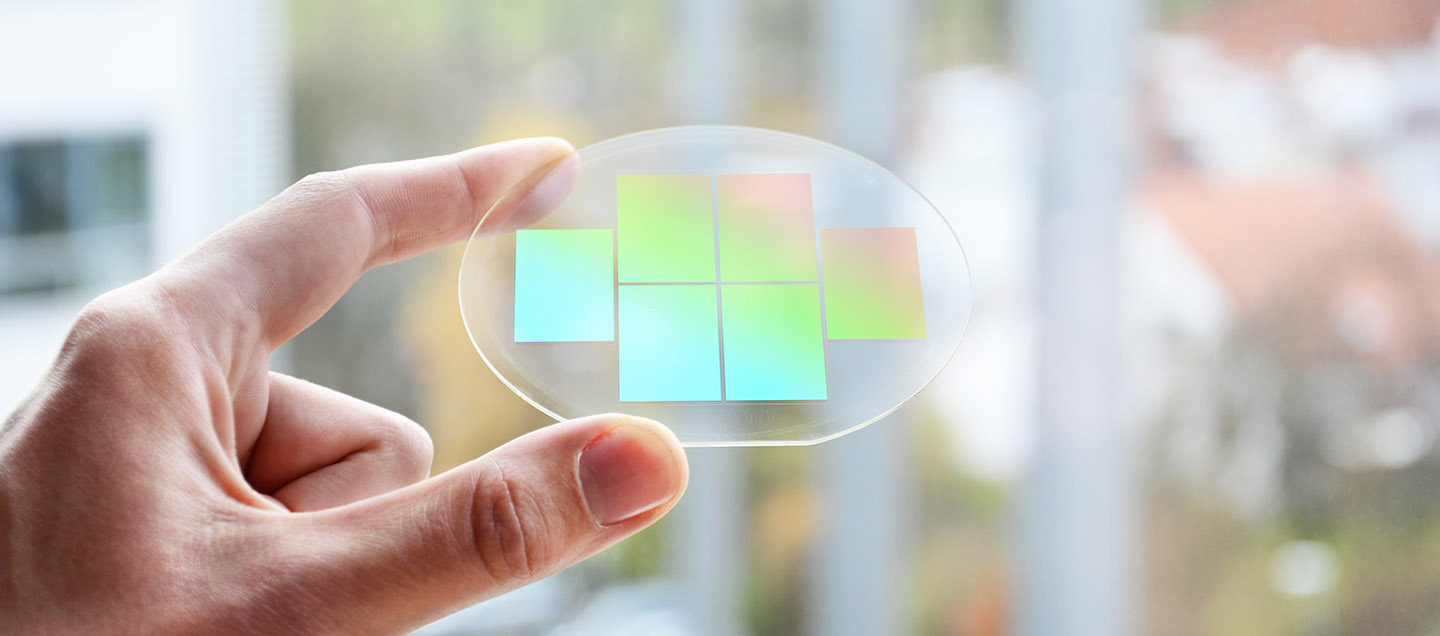

The generation and replication of optical micro- and nanostructures is the basis for modern complex optical systems. The technology available at Fraunhofer IOF - such as grayscale lithography, electron beam lithography, reactive ion etching, step & repeat replication, wafer-scale fabrication, or even molding techniques - allows the fabrication and characterization of high-end micro- and nanooptical elements of the highest resolution on up to 12" substrates and also on curved surfaces. Fields of application are for example diffraction gratings, CGHs (computer-generated holograms), microlens arrays, diffusers, or stochastic structures. Lithographic techniques allow the simultaneous production of a large number of elements with the highest lateral accuracy. As an extremely flexible direct-writing process, maskless grayscale lithography allows the generation of high-precision microstructures and surface profiles.